Method for selecting scheelite at normal temperature

A scheelite, normal temperature technology, applied in the field of scheelite flotation, can solve the problems of large fluctuations in sorting index, ore adaptability is not as good as heating, and low cost of beneficiation, so as to reduce water environmental pollution and improve recovery rate , the effect of reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Blending: will contain WO 3 0.42% scheelite raw ore is injected into the flotation machine after grinding and grading, adjust the slurry concentration to 30% and the slurry pH value to about 9, and stir for 5 minutes.

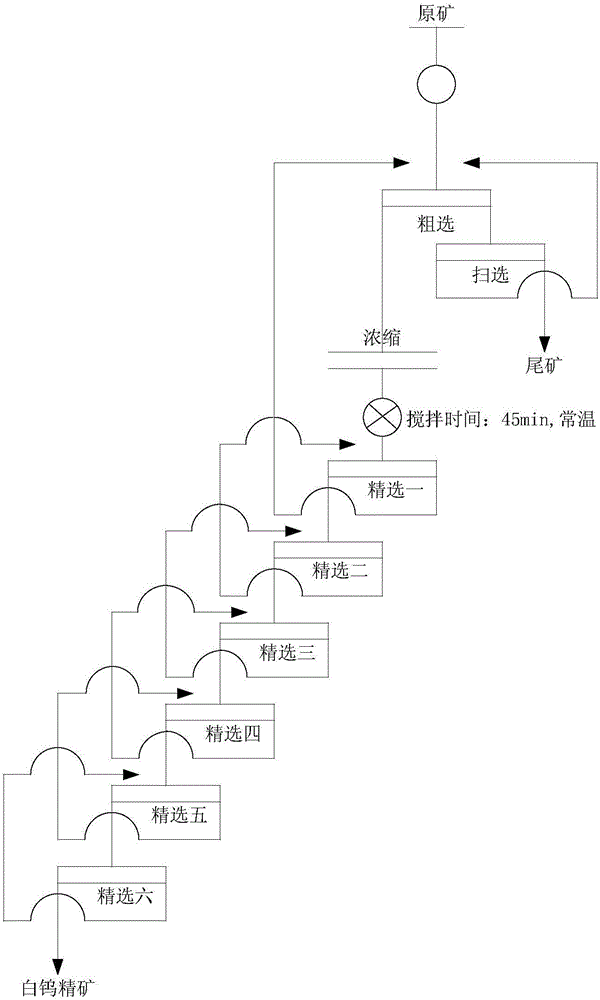

[0023] 2) Rough selection: add yfb312 inhibitor (water glass and sodium humate, the weight ratio of the two is 10:1) 1600g / t, stir for 3min, then add the combined collection of sodium oleate and benzhydroxamic acid Agent 800g / t, through flotation to obtain scheelite coarse concentrate.

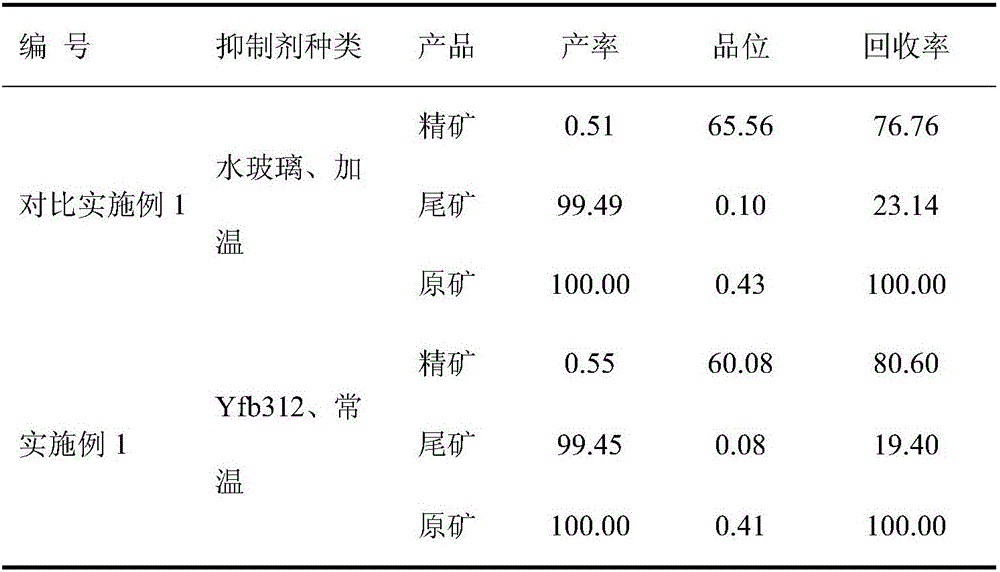

[0024] 3) Concentration: Concentrate the scheelite crude concentrate to 60%, use yfb312 (water glass and sodium humate, the weight ratio of the two is 10:1) as the inhibitor, the dosage is 1500g / t, and cool at room temperature After vigorously stirring for 30 minutes under the action of a magnetic field, dilute to a mass concentration of 30%, and obtain scheelite concentrate through six closed-circuit processes of blank selection.

[0025] Contrasting the concrete ...

Embodiment 2

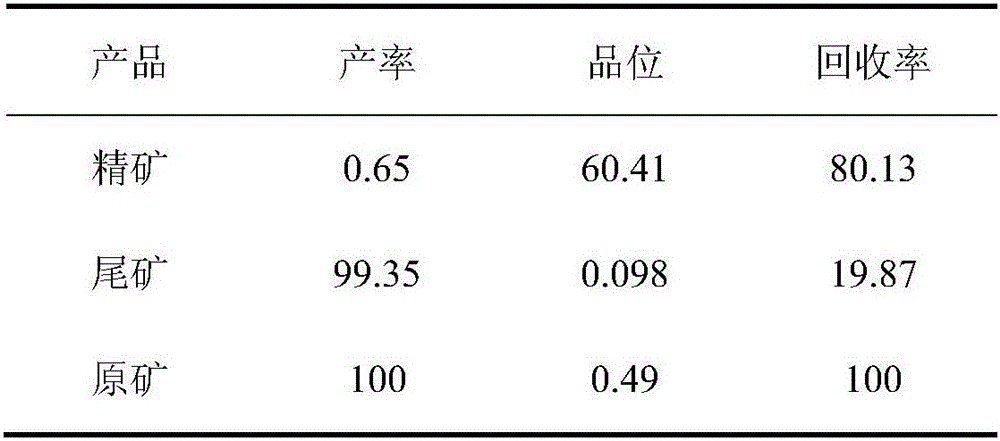

[0030] 1) Blending: will contain WO 3 The 0.49% scheelite raw ore is injected into the flotation machine after grinding and grading, and the slurry concentration is adjusted to 33% and the pH value of the slurry is about 9, and stirred for 5 minutes.

[0031] 2) Rough selection: add yfb312 inhibitor (water glass and sodium humate, the weight ratio of the two is 10:1) 1650g / t, stir for 3min, then add the combined collection of sodium oleate and benzhydroxamic acid 750g / t of scheelite is used for rough separation of scheelite to obtain rough concentrate of scheelite.

[0032] 3) Selection: Concentrate the scheelite coarse concentrate to 60%, use yfb312 (water glass and sodium humate, the weight ratio of the two is 10:1) inhibitor, the dosage is 1800g / t, and the normal temperature magnetic field After stirring vigorously for 40 minutes under action, dilute to a mass concentration of 30%, and obtain scheelite concentrate through a closed-circuit process of six times of blank sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com