Fuel oil pre-atomization device, fuel oil atomization joint and manufacturing method of fuel oil pre-atomization device

A technology of fuel atomization and fuel oil, which is applied to combustion engines, internal combustion piston engines, injection devices, etc., can solve the problems of unfavorable fuel full combustion, inability to realize fine filtration and pre-atomization of fuel, and achieve good pre-atomization effect , Avoid impurity stuck, guarantee cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

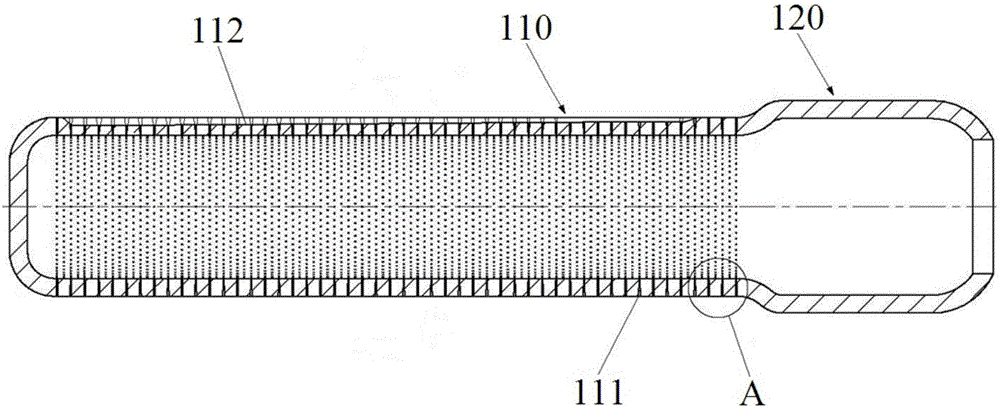

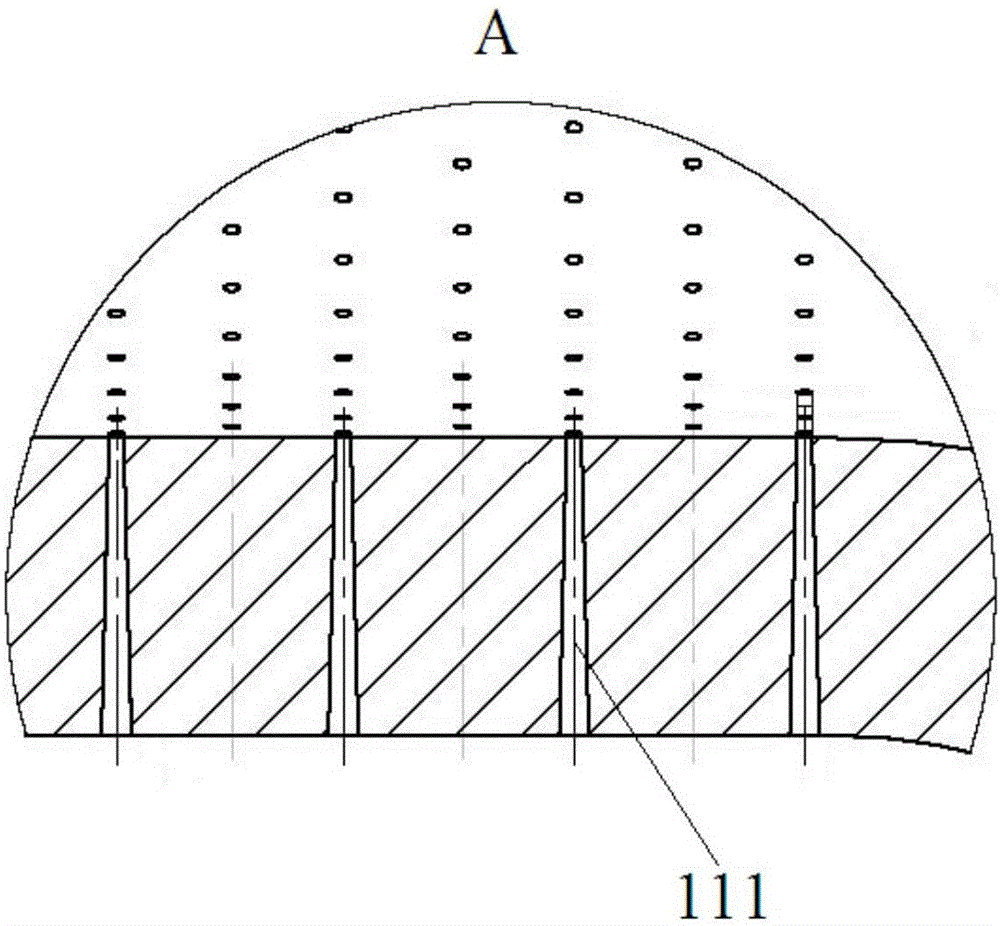

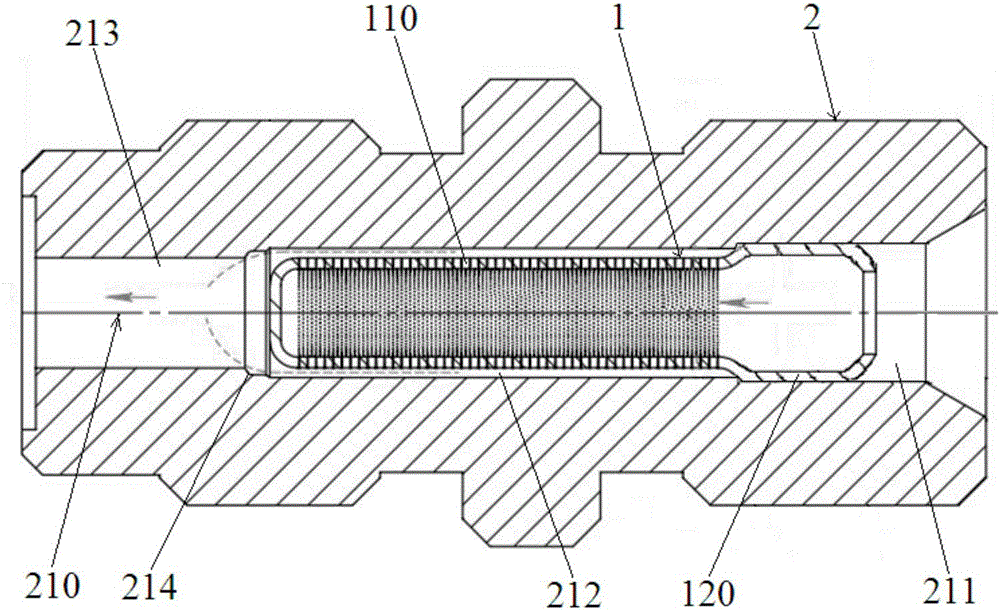

[0031] like figure 1 and figure 2 As shown, a fuel pre-atomizer provided according to an embodiment of the present invention includes a cup-shaped body 1, one end of the cup-shaped body 1 is a blind end, and the other end is an open end, and the cup-shaped body 1 The side wall is provided with an atomizing part 110 and a mounting part 120, the atomizing part 110 is adjacent to the blind end, the mounting part 120 is located at the open end of the cup-shaped body 1, and the atomizing part 110 A plurality of atomization holes 111 are arranged on the side wall of the side wall, and the diameter of the atomization holes 111 is 10-60um.

[0032] In the above embodiments, the fuel oil pre-atomizer is used for pre-atomizing diesel oil, and the atomizing part 110 of the cup-shaped body 1 is provided with a plurality of atomizing holes 111 with diameters ranging from 10 to 60 um, which can The diesel oil passing through the cup-shaped body 1 is pre-atomized when it flows out evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com