Auxiliary supporting fixture for circular tube cutting

A technology of auxiliary supports and fixtures, applied in welding/cutting auxiliary equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of complex structure of support fixtures, weak practical functions, expensive prices, etc., and achieve low processing difficulty and structural design. Reasonable and simple, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings, wherein the schematic embodiments and descriptions are only used to explain the present invention, but not as a limitation to the present invention.

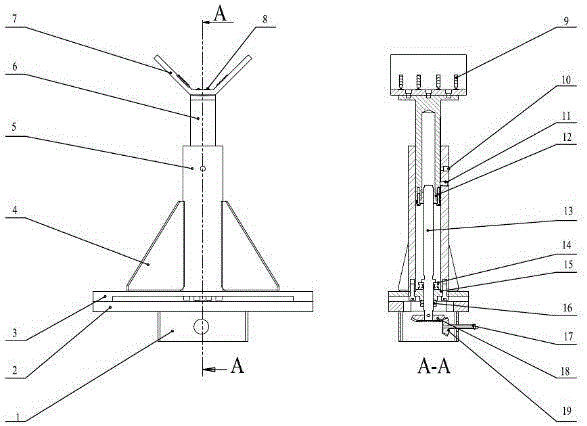

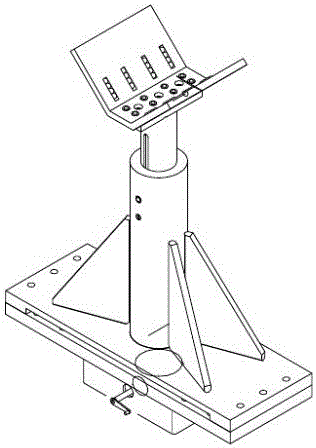

[0012] Such as figure 1 As shown, a circular pipe cutting auxiliary support fixture, the 18 driven gears in its structure are assembled with the 13 threaded shafts through positioning pins.

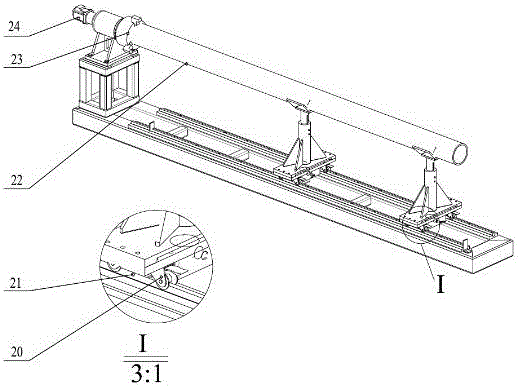

[0013] Select described 20 wheels for use, be to adopt the wheel of band braking rubber, roll on 21 hexagonal steel guide rails; 20 wheels are connected with 2 lower base plates; 2 lower base plates are connected with 3 upper base plates; The reinforcing rib is connected with the 5 sleeves; thereby driving the whole fixture to move.

[0014] The 6 lifting frames are connected with 12 ball nuts, and the 13 threaded shafts cooperate with the 12 ball nuts to form a screw nut pair. The shaft rotates to push the 12 ball nuts to rise or f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com