Automobile door framework structure

A skeleton structure, automobile door technology, applied in doors, vehicle parts, transportation and packaging, etc., can solve the problems of heavy weight, unfavorable cost, single structure, etc., and achieve strong adjustable plasticity, simplified production process, and good structural stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

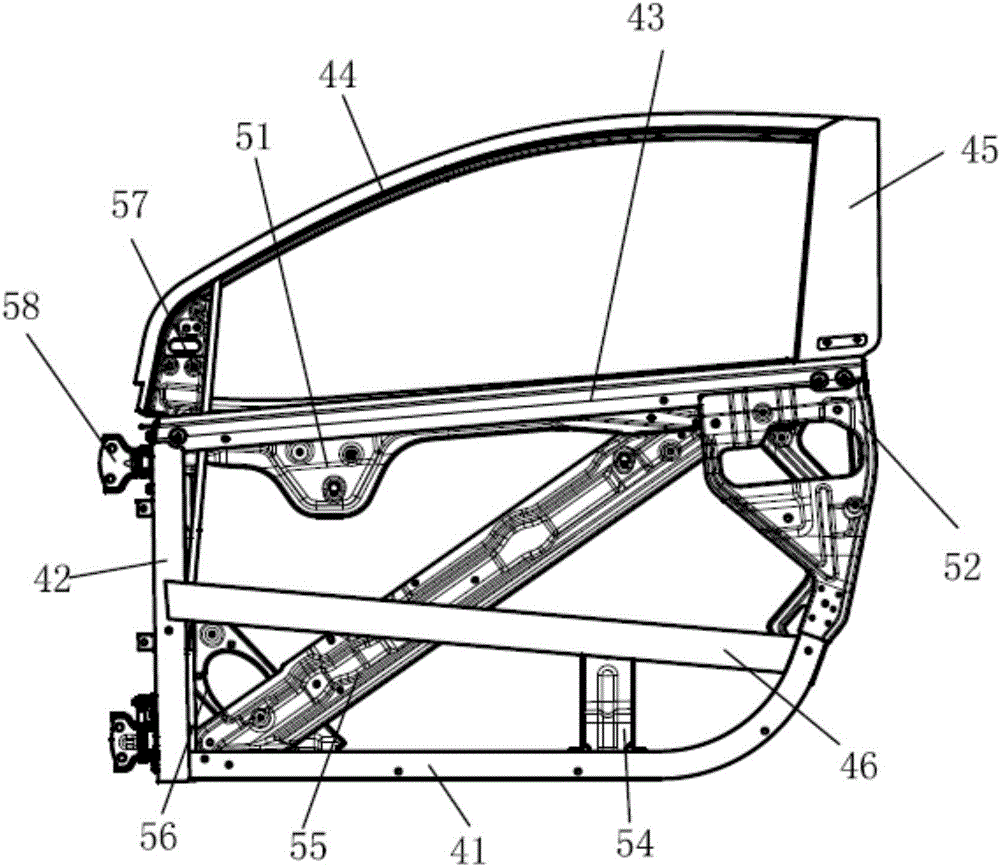

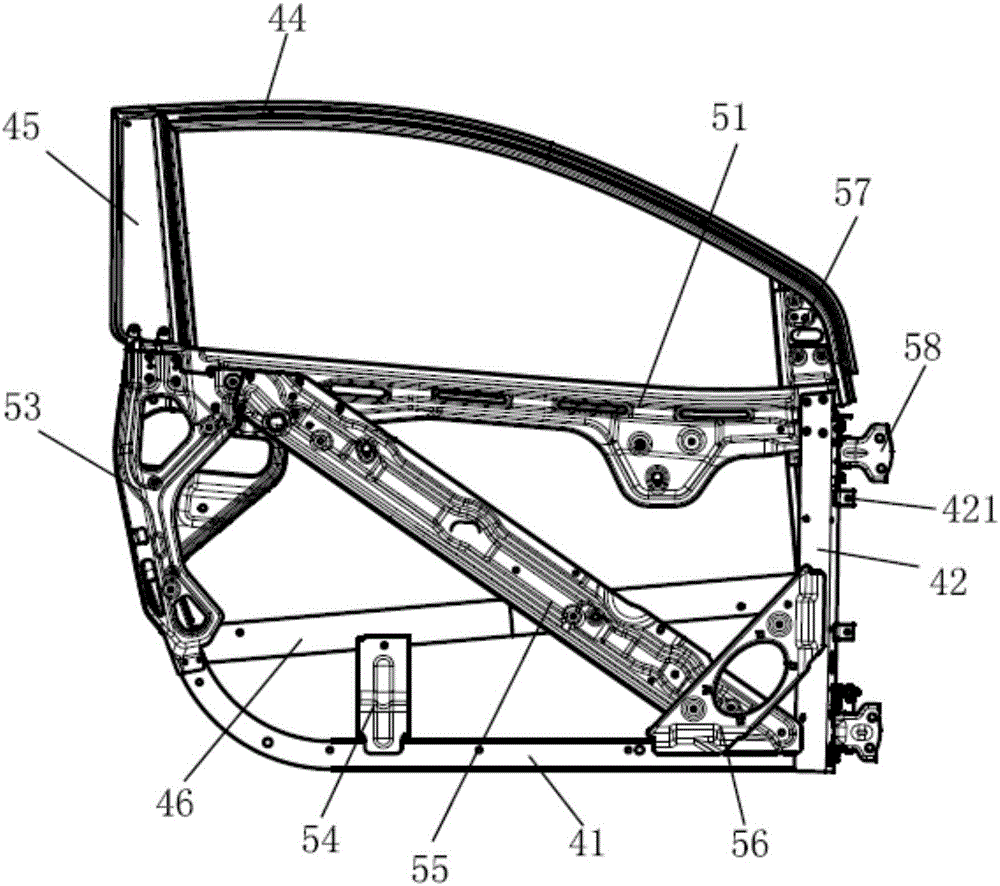

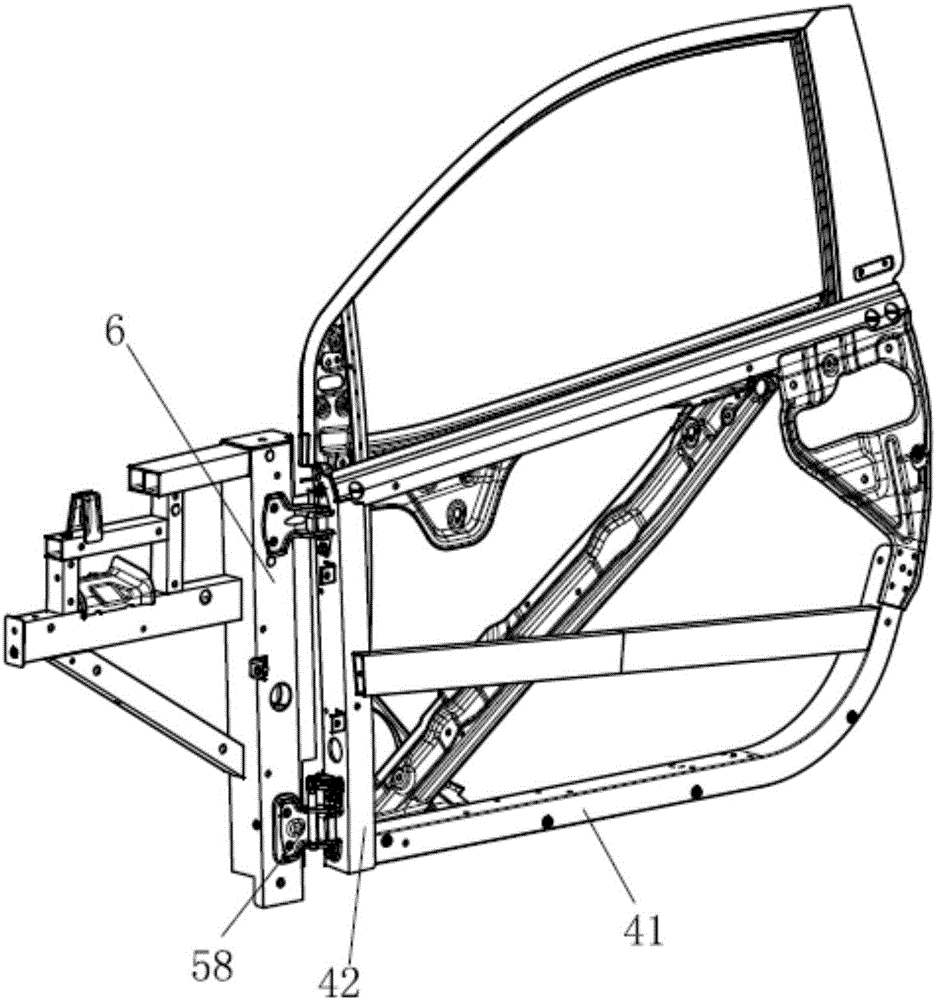

[0028] The car door skeleton structure of the present invention, as figure 1 , 2 As shown, it includes the lower frame of the car door and the window frame structure connected to the lower frame. The lower frame includes the lower frame of the car door 41, the front end of the lower frame of the door 41 is connected to the lower end of the front frame 42 of the car door, and the upper end of the front frame 42 of the car door is connected to the outer window sill of the car door. The beam 43 is provided with a door handle reinforcement plate 53 and a door lock mounting plate 53 below the door sill beam 43. The lower frame 42 of the car door, the front frame 42 of the car door and the outer sill beam 43 of the car door are all hollow aluminum alloy profile structures. In the present invention, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com