Oil filling pipe with double-side zinc-plating structure and processing method thereof

A processing method and technology of filling pipes, which are applied in the layout combined with the fuel supply of internal combustion engines, pipeline protection, pipes/pipe joints/pipe fittings, etc., can solve problems such as incomplete galvanization, incomplete plating, and easy to be corroded, and achieve processing The method is simple, the service life is improved, and the processing cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

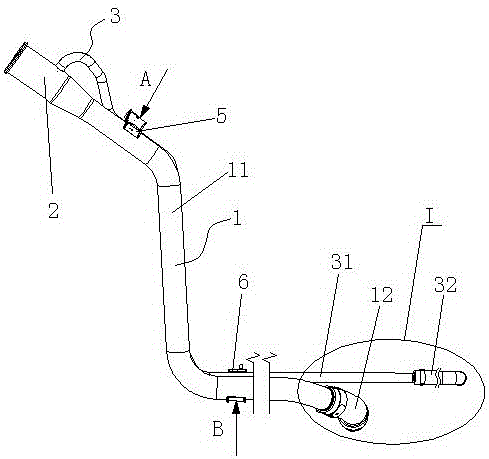

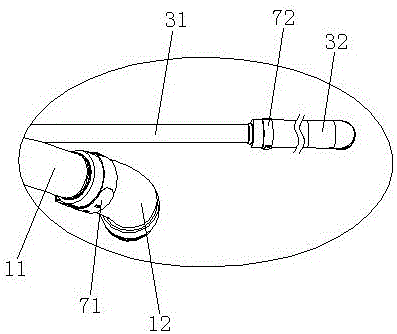

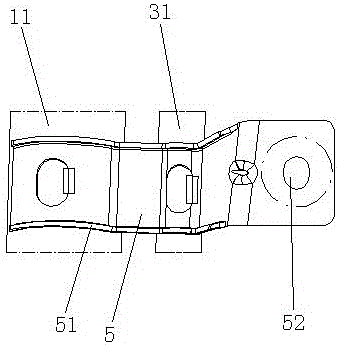

[0031] Such as Figure 1 to Figure 6 Shown is the structural representation of the present invention,

[0032] The reference signs therein are: filling pipe body 1, filling steel pipe 11, filling rubber hose 12, filling port 2, fluorocarbon resin adhesive layer 2a, connecting thread 21, tapered buffer cavity 22, ventilation pipe 3, ventilation steel pipe 31, ventilation Rubber hose 32, galvanized layer 4, first fixing bracket 5, first reinforcement edge 51, first installation hole 52, second fixing bracket 6, second reinforcement edge 61, second installation hole 62, first clamp 71, The second clip 72 .

[0033] Such as Figure 1 to Figure 6 as shown,

[0034] A refueling pipe with a double-sided galvanized structure, including a refueling pipe body 1, the refueling pipe body 1 is formed by connecting and fixing a refueling steel pipe 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com