Water displacement type steel plate lubrication and rust prevention oil

A lubricating anti-rust, water replacement technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of easy rust and other problems, achieve long anti-rust time, ensure long-term durability, and low viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

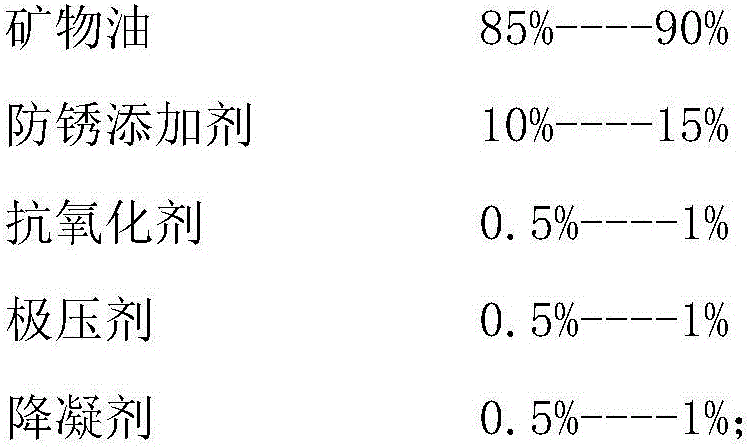

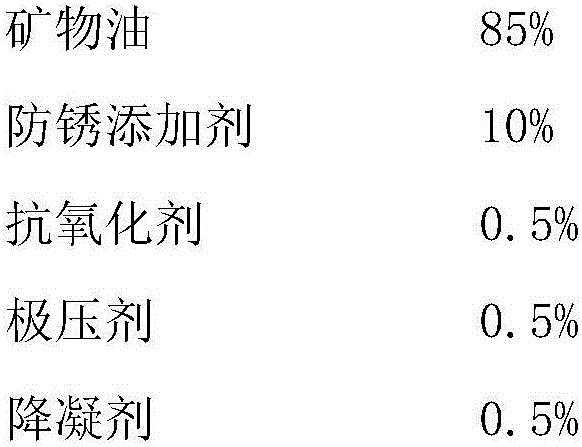

[0019] Embodiment 1: formula is:

[0020]

[0021] The production method is:

[0022] Add antirust additives, antioxidants and extreme pressure agents to mineral oil together, heat to 85±5°C and stir for about 60±5min to confirm that the solution is transparent, then add pour point depressant and another mineral oil to the solution, and then Stir at 40±5°C for about 20±5min, and pack it in barrels for storage after passing the QC test.

[0023] In the foregoing, the antirust additive is a sulfonate.

[0024] In this example, the quality characteristics of the lubricating and antirust oil for water-displaced steel plates are that a small amount of water is allowed to remain on the steel plate, and the requirements for drying the steel plate are not so harsh, so that the process requirements are reduced, energy is saved, and the use effect is improved. In order to completely prevent rust on the surface of the steel plate for a period of time.

[0025] The invention is suit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com