Large-span bamboo truss structure roof with heat insulation function and construction process thereof

A technology of truss structure and function, applied in the direction of truss structure, roof covering, roof, etc., can solve the problem that the bearing capacity cannot meet the requirements of design and use, can not achieve full utilization of materials, and cannot meet the requirements of economy, etc. On-site assembly is simple, the material is green and environmentally friendly, and the deflection is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

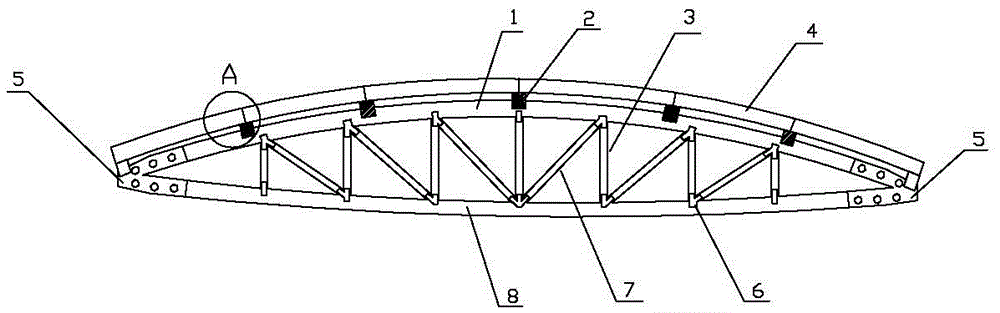

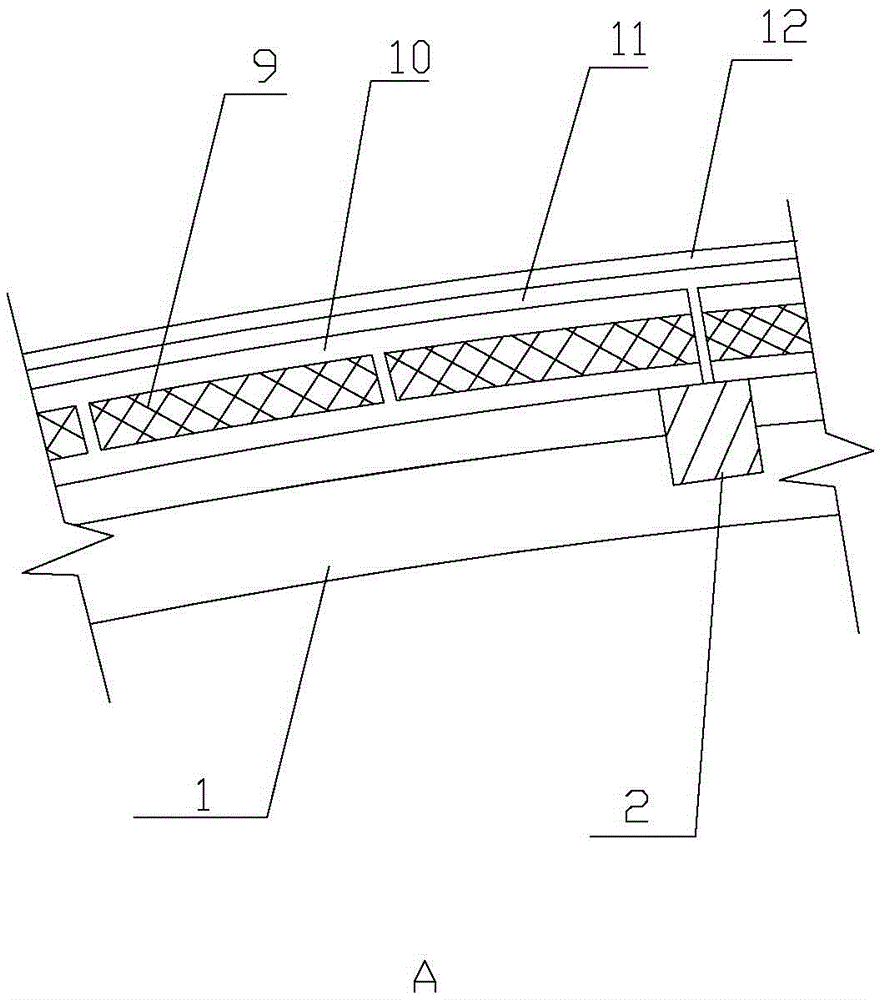

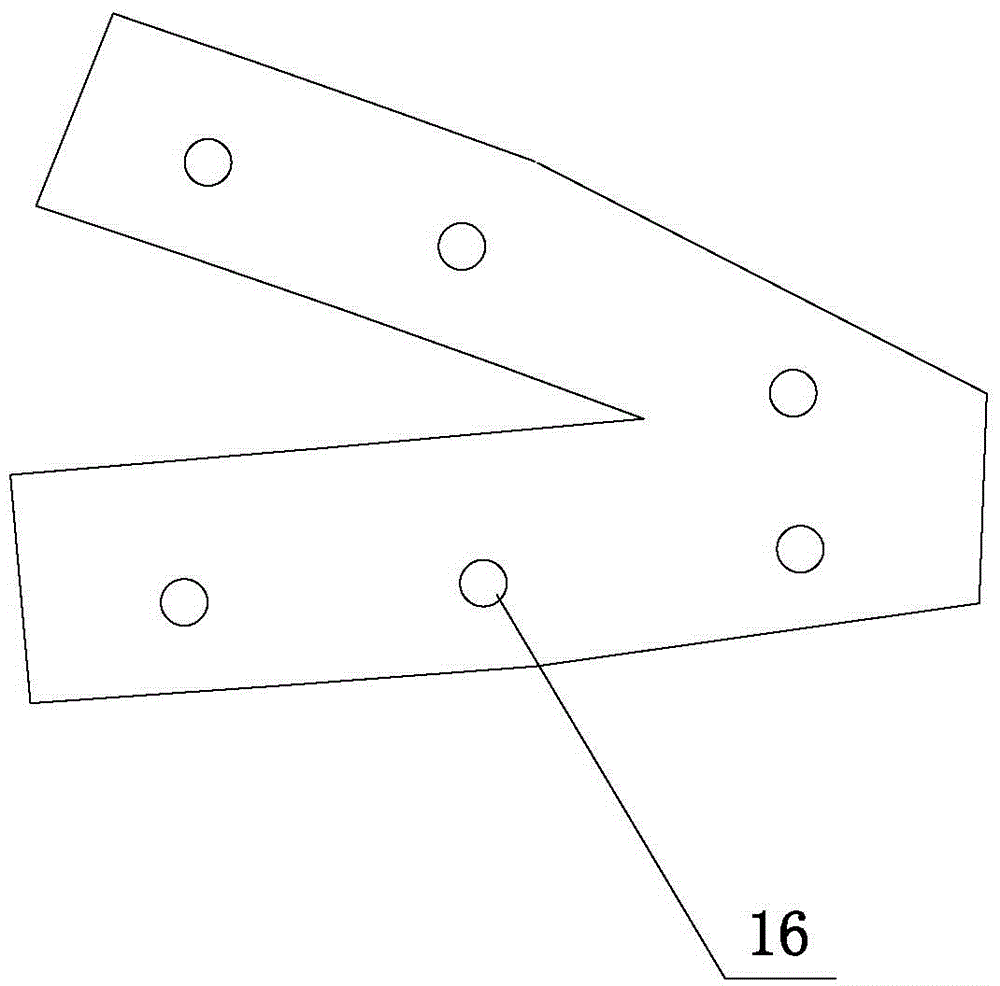

[0034] Such as figure 1 and 2 As shown, a long-span bamboo truss structure roof with thermal insulation function includes multiple trusses. Each truss is composed of a chord and a web; both the chord and the web are made of bamboo, for example, glued bamboo can be used. The chord includes an upper chord 1 and a lower chord 8 which are both arc-shaped, and are connected to each other at both ends, so that an ellipse is formed between the upper chord 1 and the lower chord 8 . The webs include a plurality of vertical webs 3 and oblique webs 7 in the form of straight rods. Wherein, the vertical web 3 is vertically arranged between the upper chord 1 and the lower chord 8, and an oblique web 7 is arranged between every two vertical webs 3, so that all The two ends of each oblique web 7 are connected to the upper and lower ends of two different vertical we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com