Three-way catalyst assembly

A three-way catalytic converter and assembly technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as the fracture of the intake end cone, and achieve the effects of firm installation, weight reduction, and enhanced strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

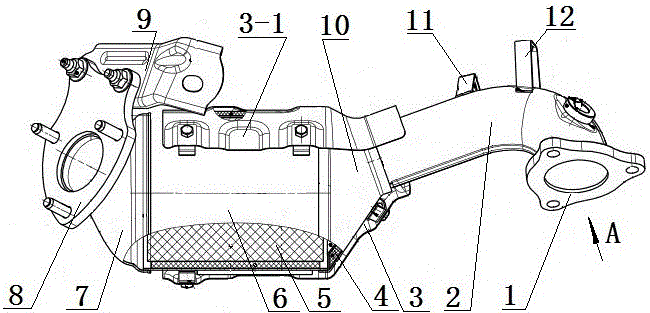

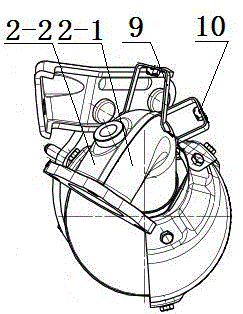

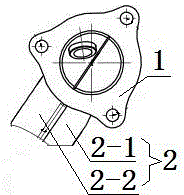

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing:

[0013] Such as figure 1 , figure 2 and image 3 The shown three-way catalytic converter assembly includes a cylinder body 6 with a catalyst assembly 5 inside, one end of the cylinder body 6 is connected to the gas outlet flange 8 through the gas outlet end cover 7, and a heat insulation device is installed on the gas outlet flange 8 through bolts. The bracket 9; the other end of the barrel 6 is connected to the air intake pipe 2 through the air intake end cover, and the air intake end cover has an air intake inner end cover 4 and an air intake outer end cover 10 set outside the air intake inner end cover 4; The front end of the intake pipe 2 is welded with an intake flange 1, and the intake pipe 2 is formed by butt welding of the intake pipe I half-shell 2-1 and the intake pipe II half-shell 2-2 to enhance the strength and rigidity of the intake pipe; The air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com