A system and method for measuring surface pressure of pump impeller blades

A technology of impeller blades and surface pressure, applied in pump control, non-variable pumps, machines/engines, etc., to achieve high resolution, strong received signal, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

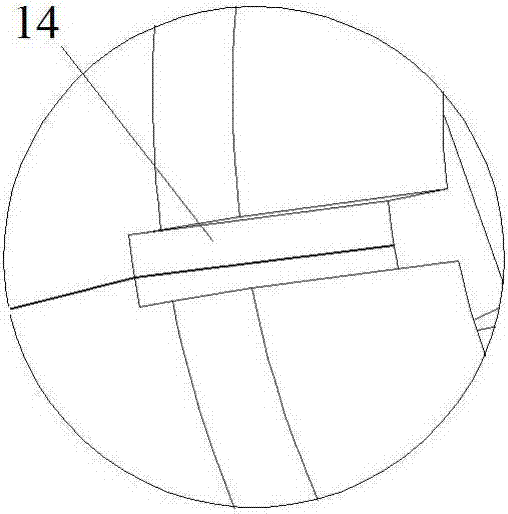

[0031] A centrifugal pump with a specific speed of 165, its main parameters are: the width of the impeller outlet b 2 =37mm, impeller outlet diameter D 2 =278mm, impeller hub diameter d h =37mm, pump shaft diameter d=25mm.

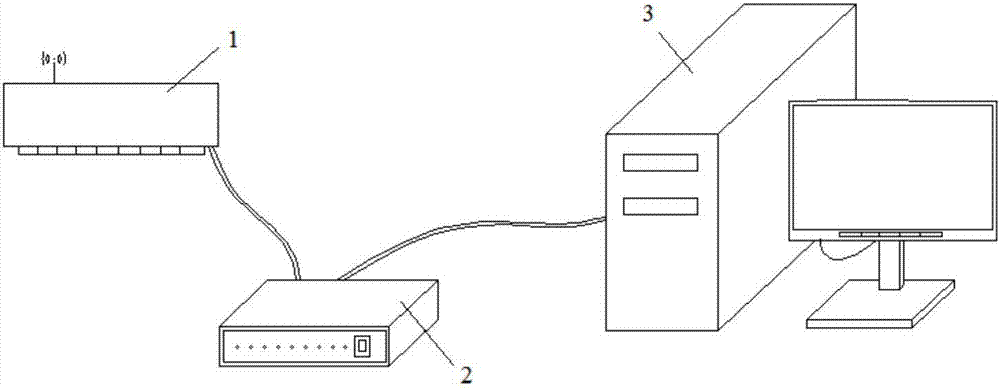

[0032] as attached figure 1 As shown, after the pressure vibration signal of the impeller blade of the pump device is measured by the measuring point of the piezoelectric film sensor 5, it is transmitted to the signal sending device 18 through the lead wire 6, and the signal sending device 18 converts the pressure signal into a digital signal for wireless transmission , the signal receiving device 1 receives the digital signal sent by the signal sending device 18 through its external trigger, and transmits the digital signal to the data acquisition and monitoring system 2. After the pressure signals of all measuring points are measured, the digital signal is transmitted to the computer 3 for analysis.

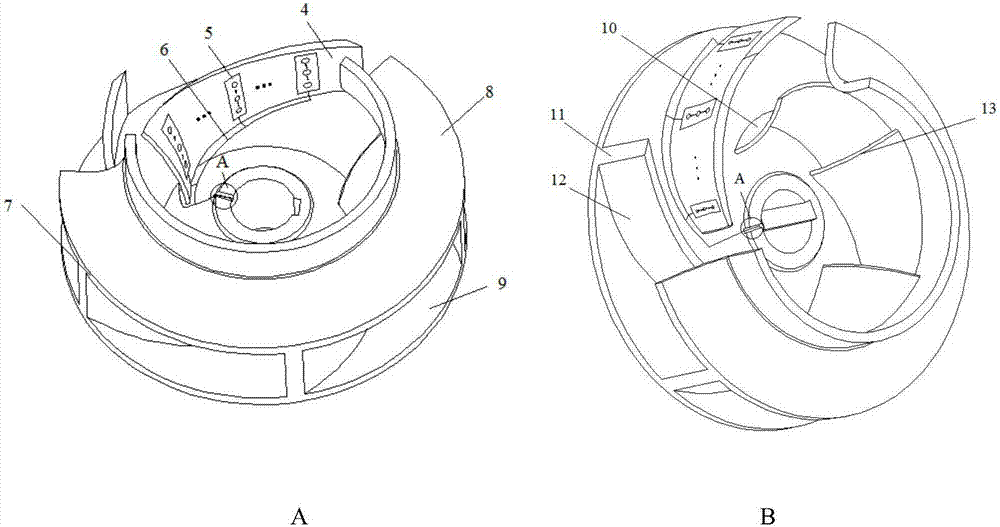

[0033] as attached figure 2 As shown, on the im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com