Lead screw thread bottom hardness micro-magnetic nondestructive detection method

A non-destructive testing and screw-tooth technology, applied in the direction of measuring device, material magnetic variable, material analysis by electromagnetic means, etc., can solve the problem that the depth of the hardened layer of the screw cannot be reflected, and reduce the influence of the skin effect of the material. The effect of shortened inspection time and non-destructive inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

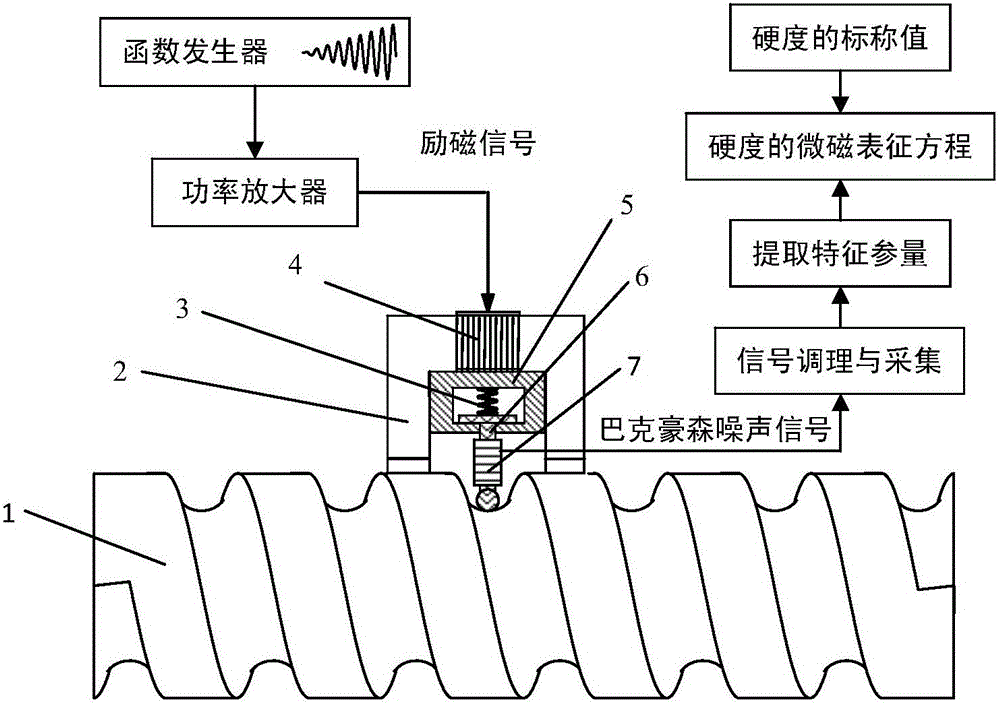

[0022] The steps of the micromagnetic nondestructive testing method mainly include:

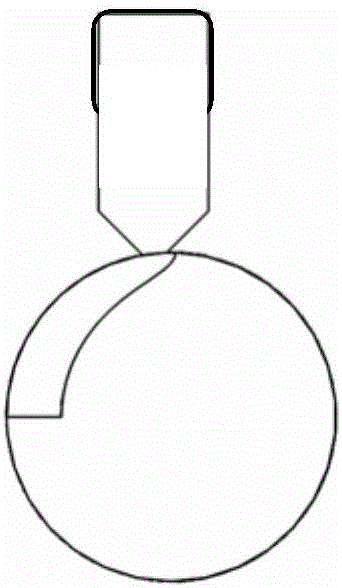

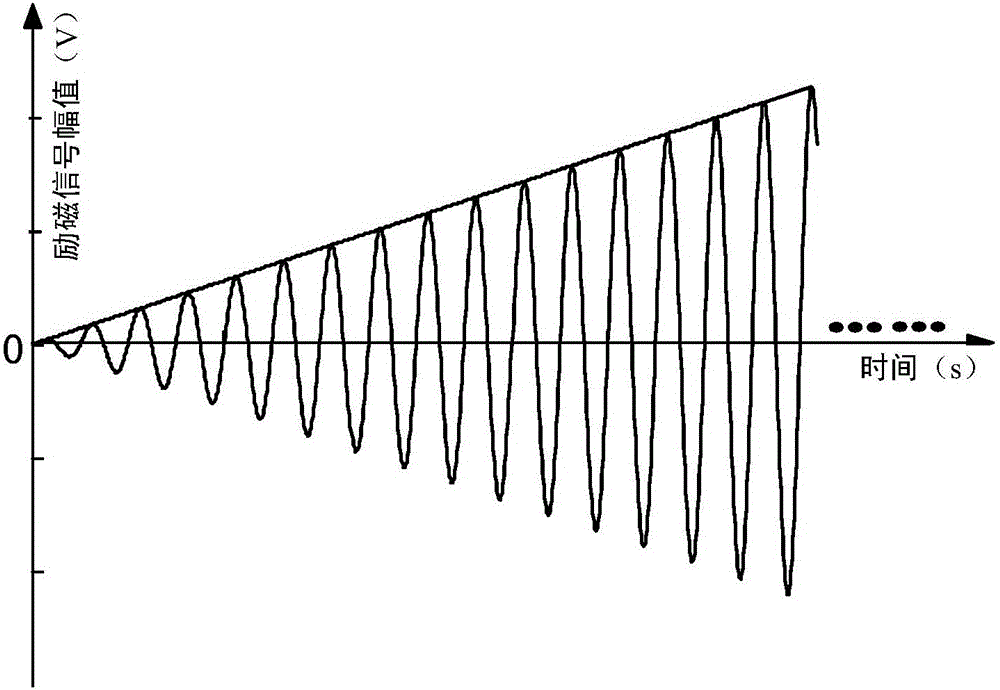

[0023] Fit the two pole pieces of the micro-magnetic probe closely on the two adjacent crests of the lead screw, so that the electromagnet and the lead screw form a closed magnetic circuit, so that the excitation signal of the excitation coil is coupled between the two crests of the lead screw , forming a stable alternating magnetic field at the bottom of the screw tooth. An arbitrary function generator provides an alternating excitation signal with a gradually increasing amplitude to AC excite the electromagnet. The excitation field passes through the excitation circuit, and the electromagnet is coupled between the two crests of the lead screw. A stable alternating magnetic field with a crescendo in amplitude is formed.

[0024] Under the action of the alternating magnetic field, due to the existence of the Barkhausen effect, the detection coil near the bottom of the screw tooth induces a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com