A magnetic flux leakage inversion method for pipeline defects based on adaboost-rbf collaboration

A defect and magnetic flux leakage technology, applied in the field of pipeline defect magnetic flux leakage inversion based on Adaboost-RBF collaboration, can solve the problems of easy failure, dependence on detection experience, low accuracy, etc., to prevent pipeline leakage, ensure generalization ability, The effect of improving calculation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

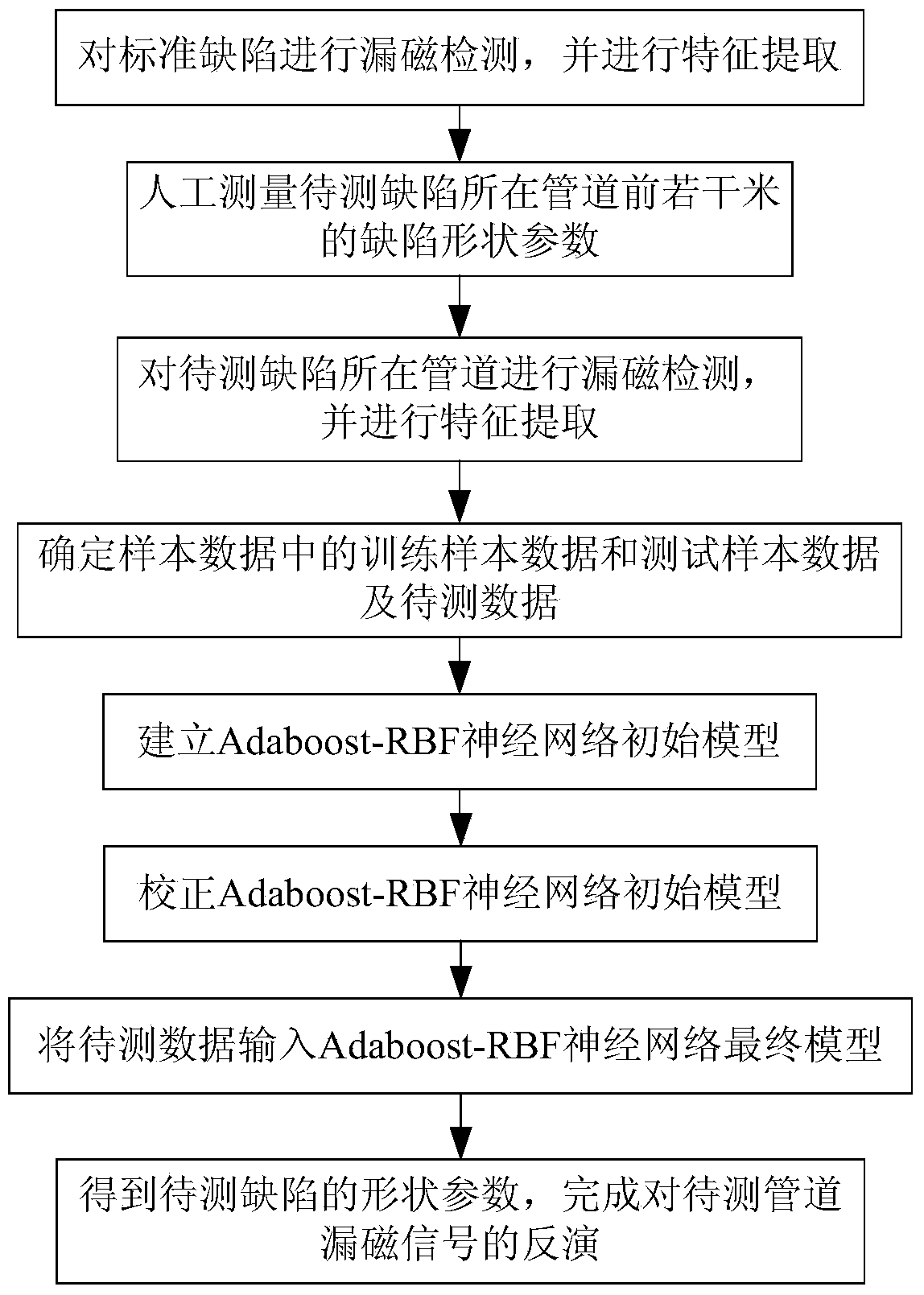

[0054] A magnetic flux leakage inversion method for pipeline defects based on Adaboost-RBF collaboration, such as figure 1 Shown is a general flowchart of the method of this embodiment, and the method of this embodiment is specifically described as follows.

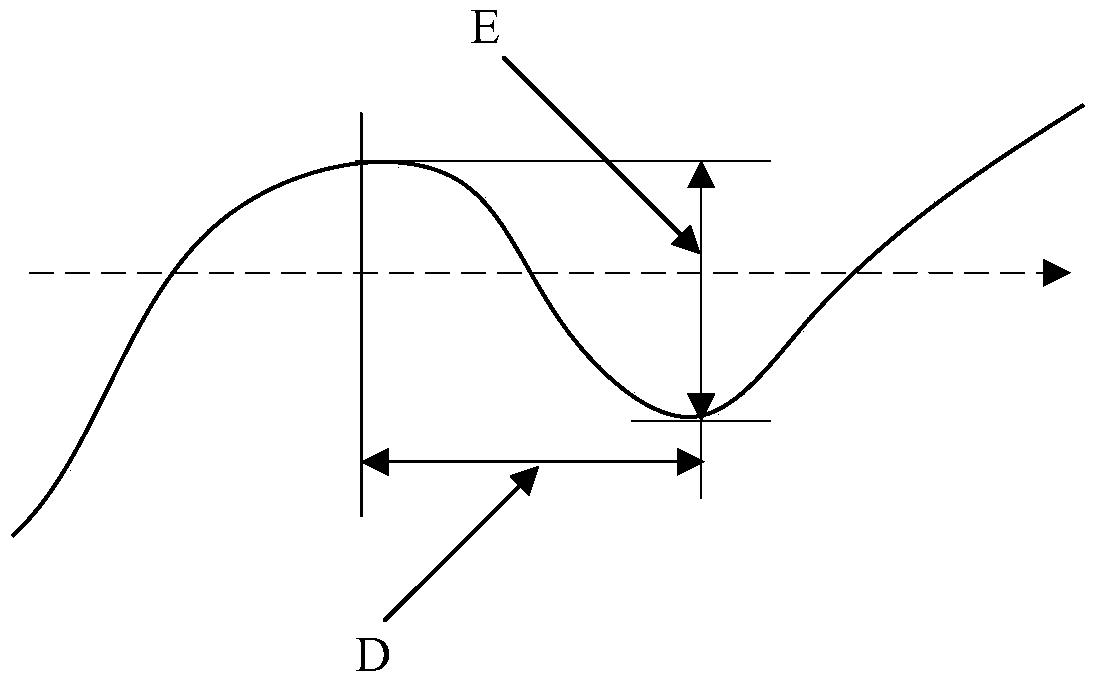

[0055] Step 1: Perform magnetic flux leakage detection on standard defects, and perform feature extraction on the magnetic flux leakage signal.

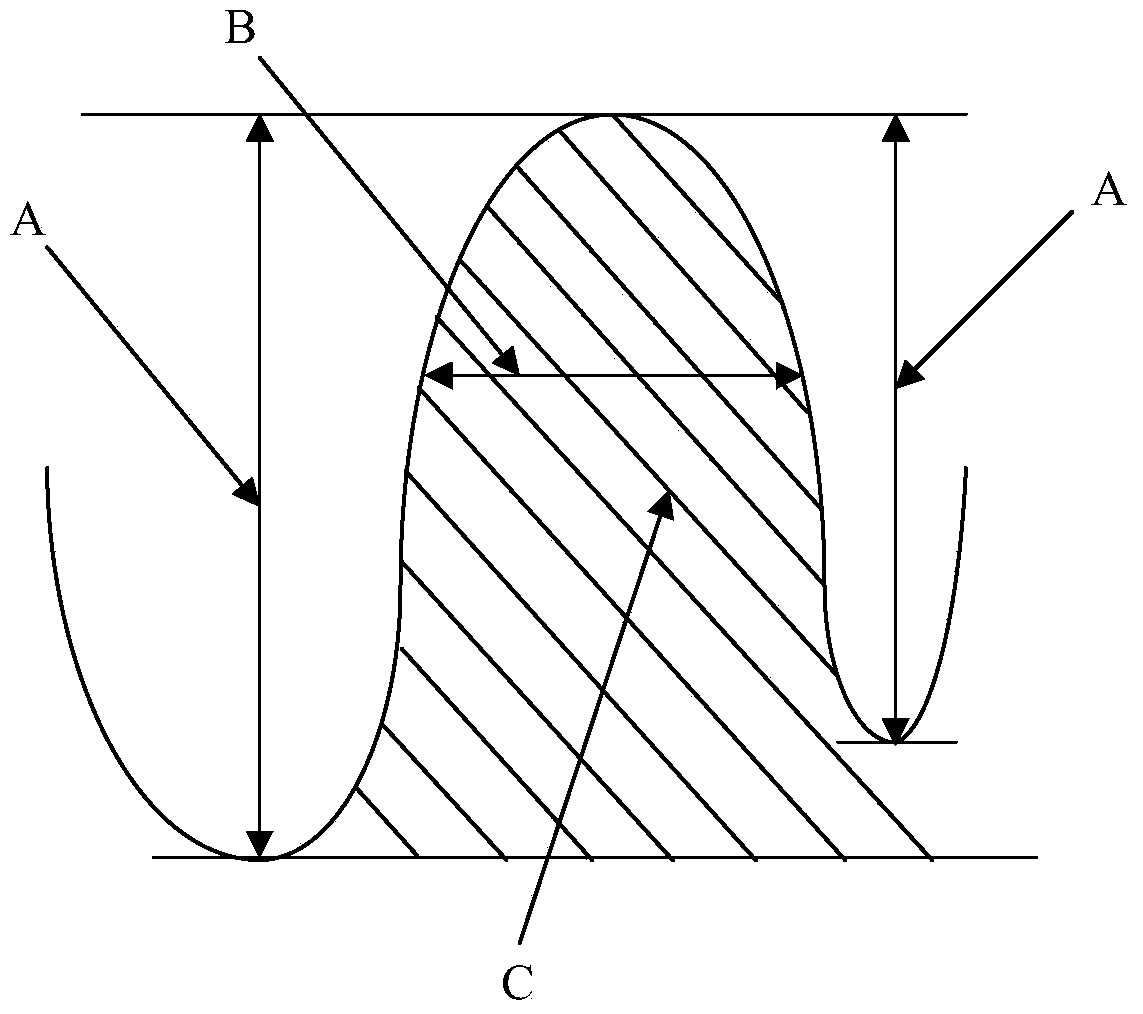

[0056] Step 101: Take a standard pipe of the same material and specification as the pipe where the defect to be tested is, and process a given standard defect on it according to the specification in Appendix B of the national standard NB / T47013.12-2015. In the specific implementation, the length of the standard pipe should be as long as the actual working conditions allow; the processed standard defect size should be classified into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com