Remaining-life predicting method for ball end mill for chrome steel blade profile

A ball-end milling cutter and life prediction technology, which is applied in the field of mechanical cutting, can solve problems such as complex mathematical models, low efficiency, and high cost, so as to fully tap the potential of tool life, improve product quality and production efficiency, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

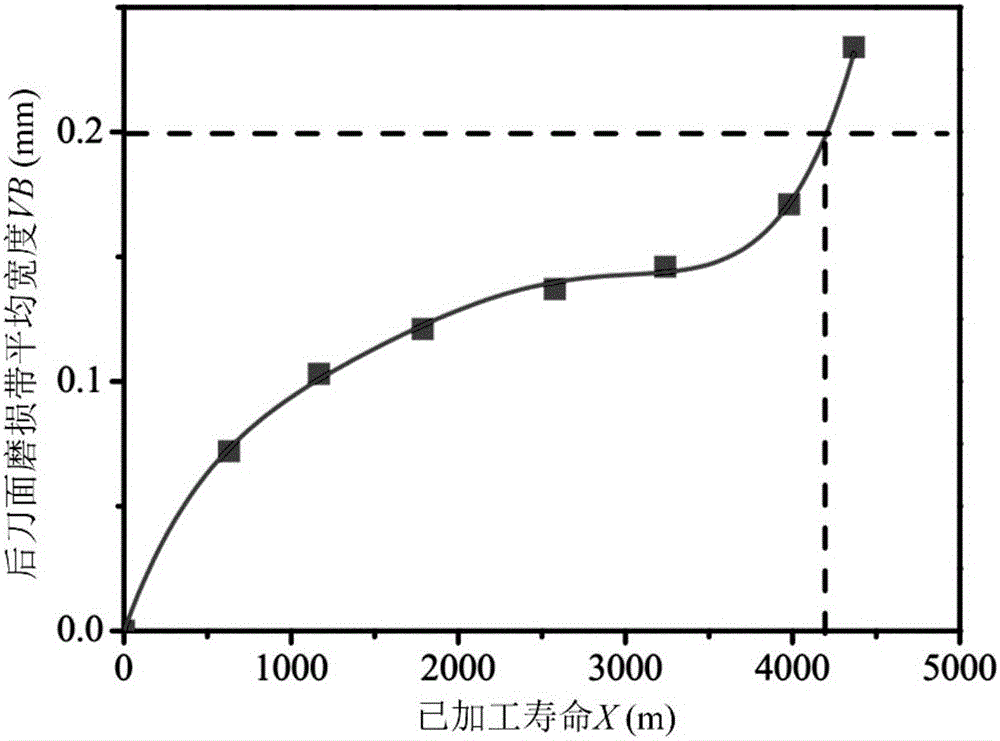

[0060] The test tool is a domestic R5 ball end milling cutter with 4 flutes, and the specific parameters are R5×4°×D16×120L. The CNC machine tool used for processing is the VMX42 five-axis linkage CNC machining center produced by the American Hurco Company, and the processed samples are chrome steel blades.

[0061] Applying the present invention to the method for predicting the remaining life of the ball end milling cutter for processing the chrome steel blade profile, the specific steps are as follows:

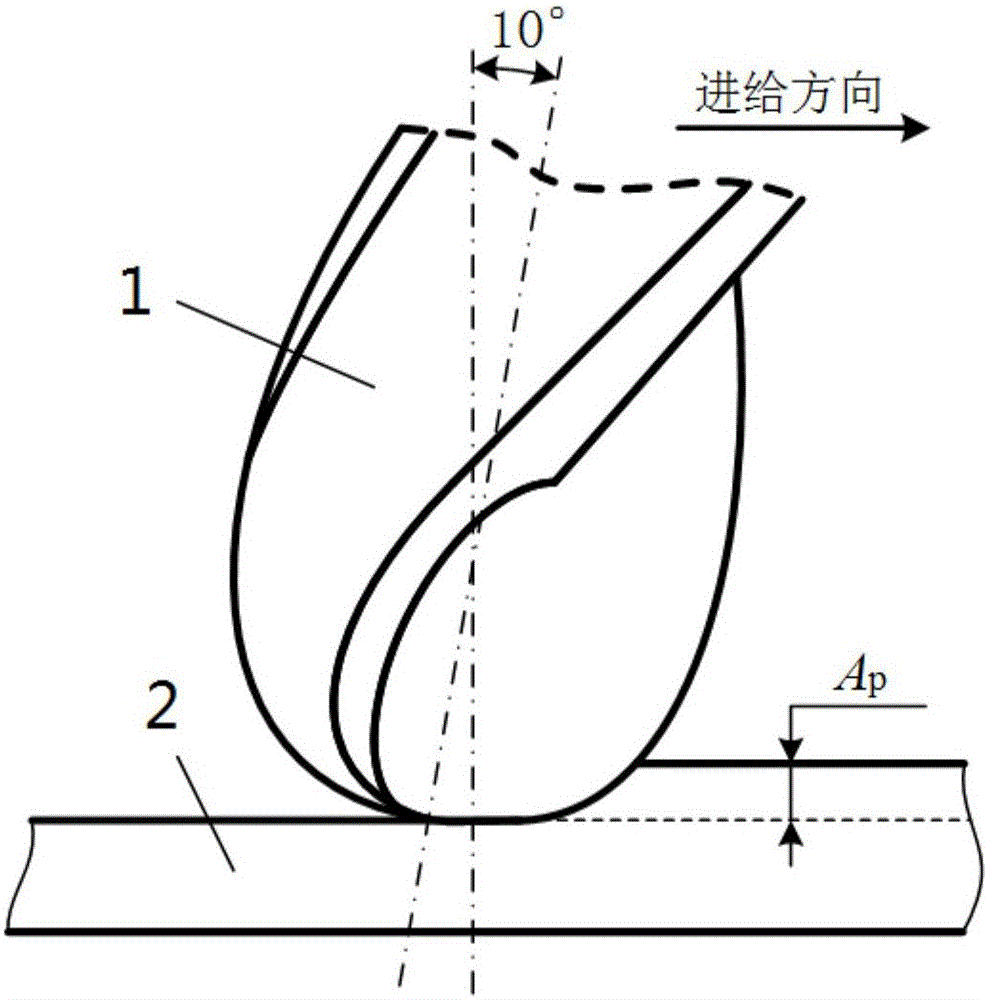

[0062] (1) Install the ball end milling cutter 1, such as figure 1 Shown, and check before starting the CNC machine tool;

[0063] (2) Fix the chromium steel blade sample 2 on the workbench through a special fixture, keep the profile face up and its outer normal deflected at an angle of 10° with the center line of the ball end milling cutter;

[0064] (3) Turn on the machine tool, at the spindle speed N 1 3800rpm, feed F 1520mm / min and cutting depth A p Under the conditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com