Automatic grain boundary extraction method for steel grain

An extraction method and a technology of grains, which are applied in the field of automatic grain boundary extraction of steel grains, can solve problems such as image brightness sensitivity and noise sensitivity, and achieve the effect of simple algorithm, fast algorithm operation speed, and reduction of false feature points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

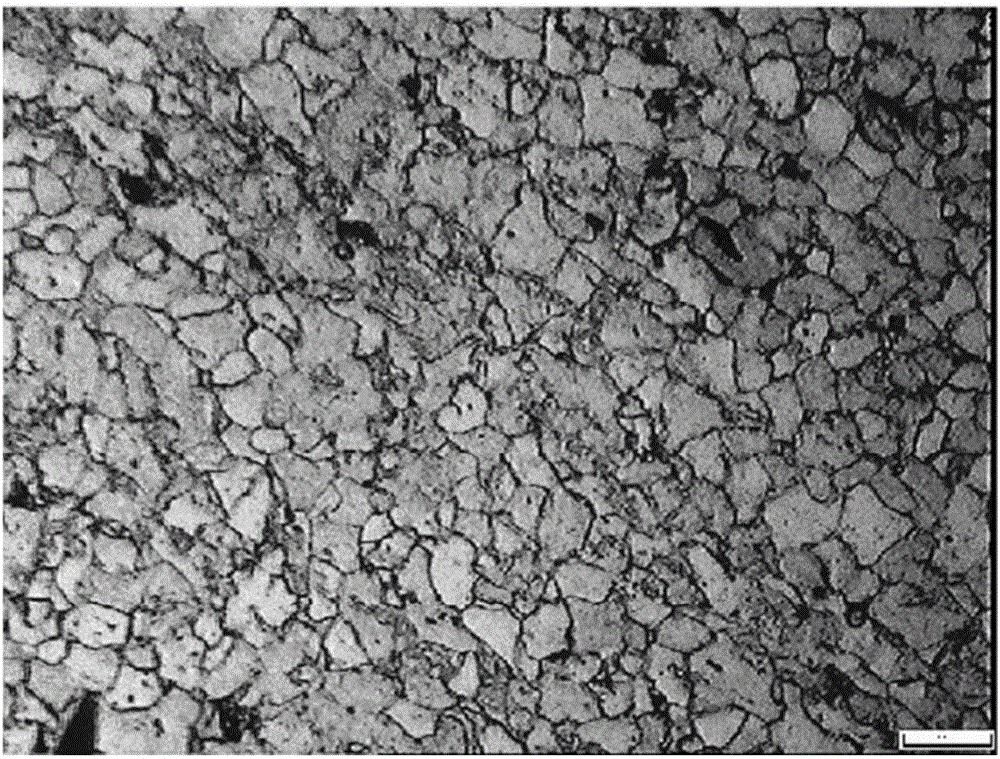

[0057] In order to deepen the understanding of the present invention, the method and extraction process of the improved automatic grain boundary extraction of steel grains in the present invention will be further described below in conjunction with the accompanying drawings.

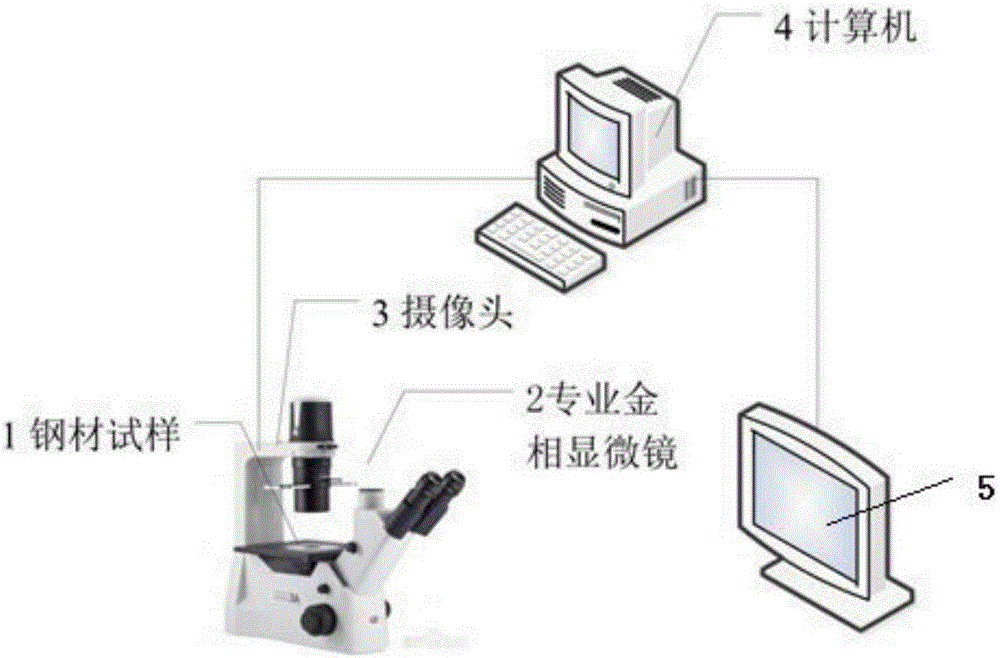

[0058] The present invention is applied to the field of metallographic quantitative intelligent analysis of the microscopic grain structure of iron and steel materials, such as figure 1 Shown is a schematic diagram of the hardware system for the automatic grain boundary extraction of the present invention. The hardware system consists of a steel sample 1, a professional metallographic microscope 2, a camera 3, a computer 4 and a display 5.

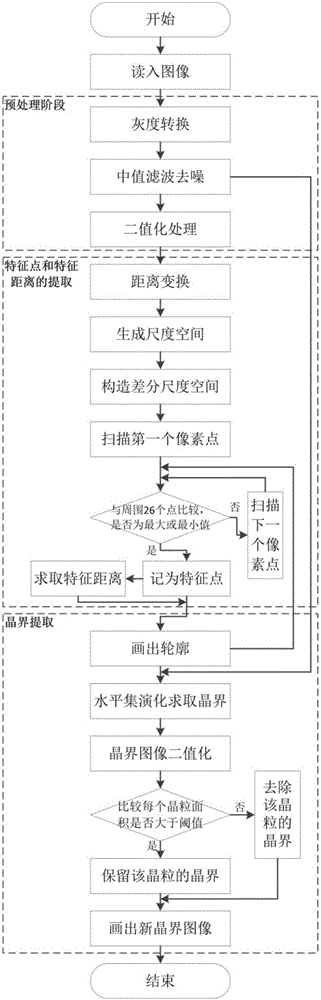

[0059] The automatic grain boundary extraction method proposed by the present invention includes the step of collecting metallographic images and the step of extracting grain boundaries from the collected metallographic images, and the specific implementation include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com