New energy AC charging gun cable

A technology of AC charging and new energy, applied in the direction of power cables, insulated cables, cables, etc., can solve the effects of cold resistance, wear resistance, oil resistance, acid and alkali resistance, water resistance, UV resistance, external pressure resistance and thermal stress. Very ideal, the outer layer of the cable is easy to harden, detachment, cable replacement and maintenance increase, etc., to achieve the effect of enhancing anti-interference performance, increasing hand feel and appearance, and safe and error-free operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

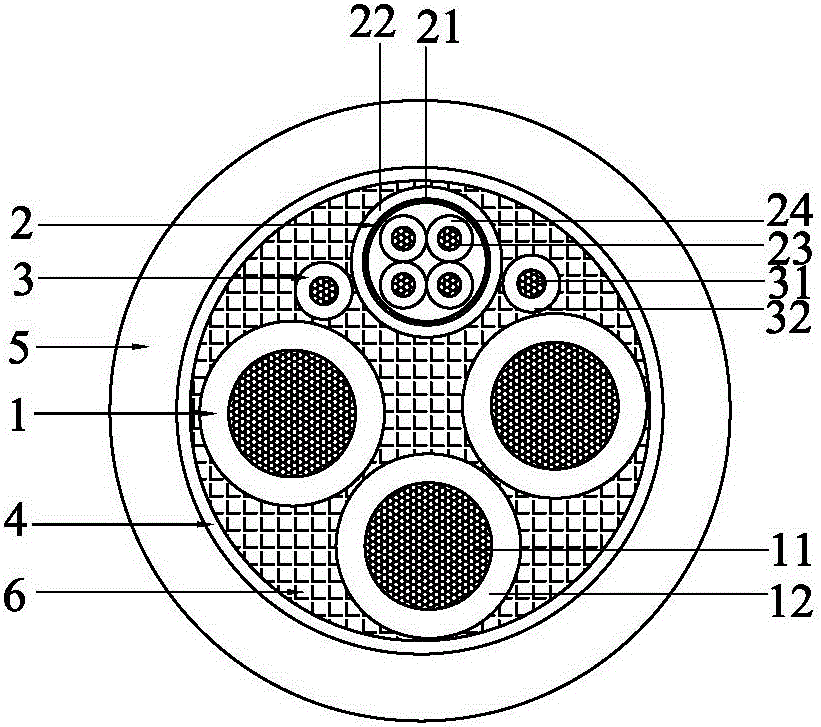

[0017] see figure 1 , a new energy AC charging gun cable provided in this embodiment, which includes a power transmission line 1, a signal transmission line 2, an auxiliary line 3, a tissue layer 4 and a TPE protective layer 5, three power transmission lines 1 and a signal transmission line 2 in the form of The center of the circle is symmetrically arranged, and the two auxiliary lines 3 are symmetrically arranged on both sides of the signal transmission line 2. The gap between the power transmission line 1, the signal transmission line 2 and the auxiliary line 3 is filled with a filler 6 to form a core line, and the tissue paper layer 4 and TPE The protection layer 5 covers the core wire sequentially from inside to outside. The thickness of the tissue paper layer 4 is preferably 2.3-2.7 mm. The thickness of the TPE protective layer 5 is preferably 24-27 mm.

[0018] Specifically, the power transmission line 1 includes a conductor 11 formed by twisting 450-550 bare copper wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com