X-ray tube

An X-ray tube and cathode technology, applied in the field of X-ray tubes, can solve problems such as leakage of X-ray tubes, and achieve the effect of suppressing punch-through discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

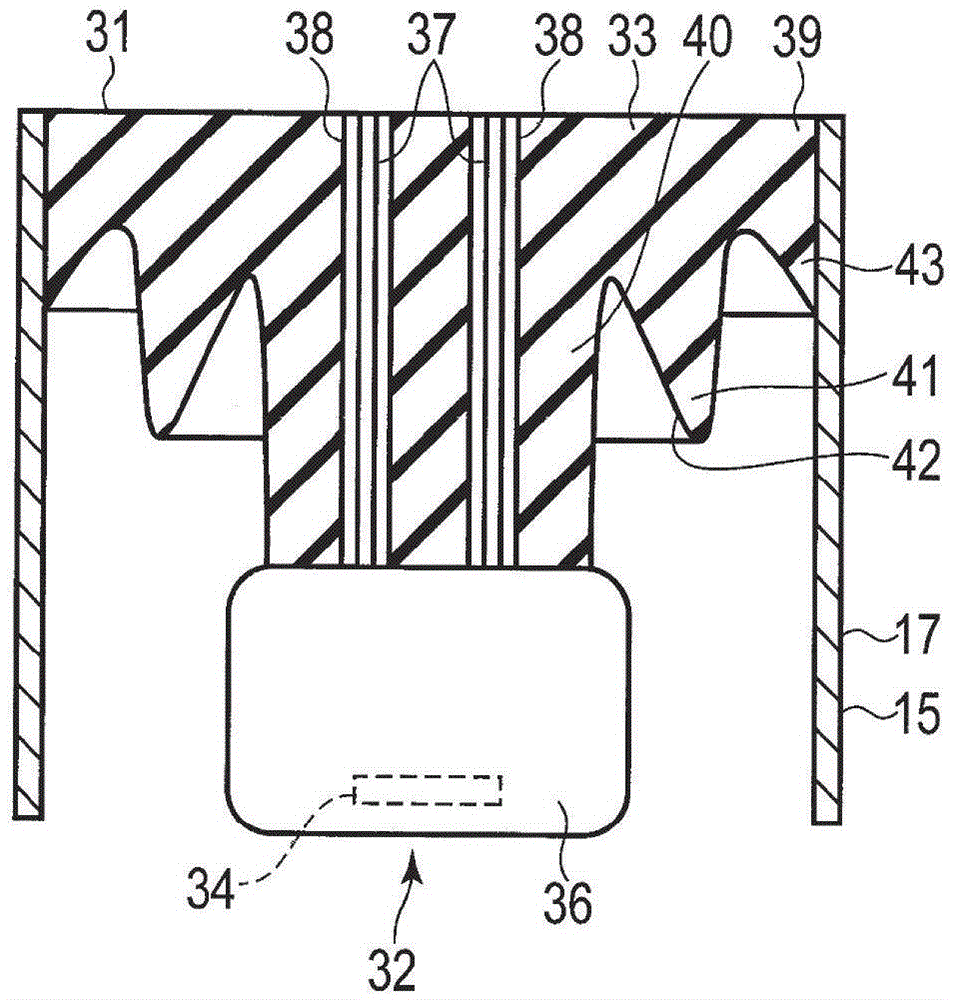

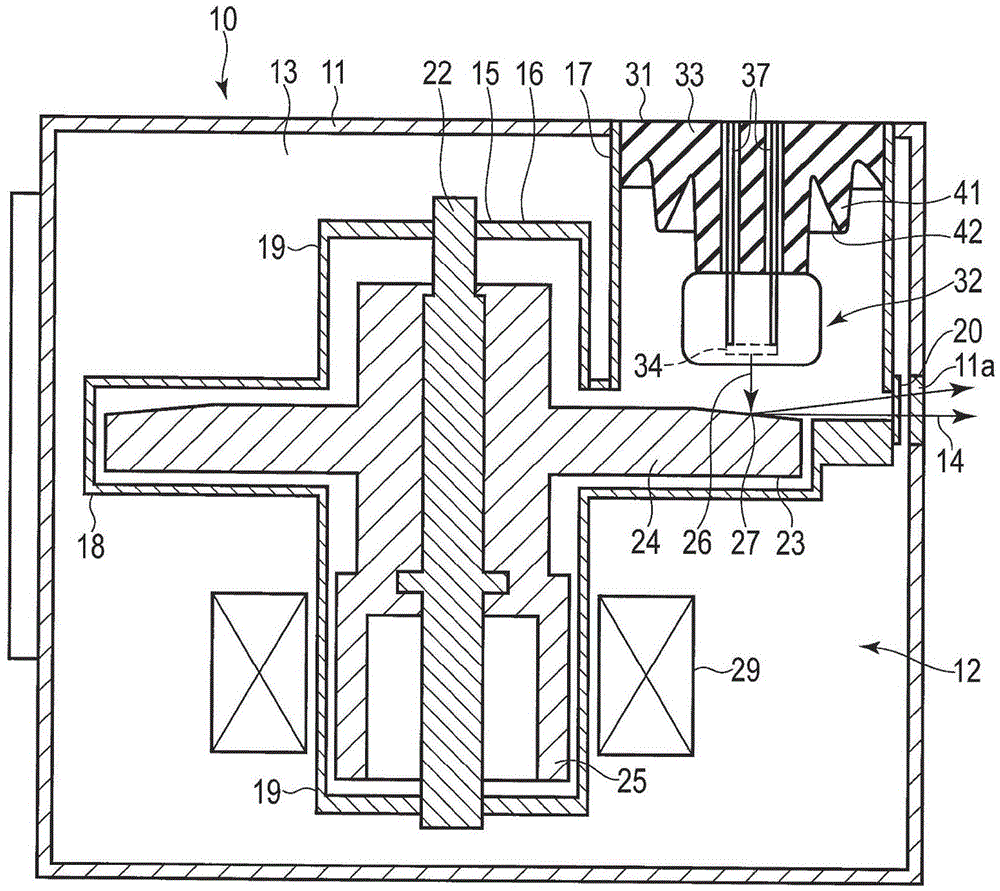

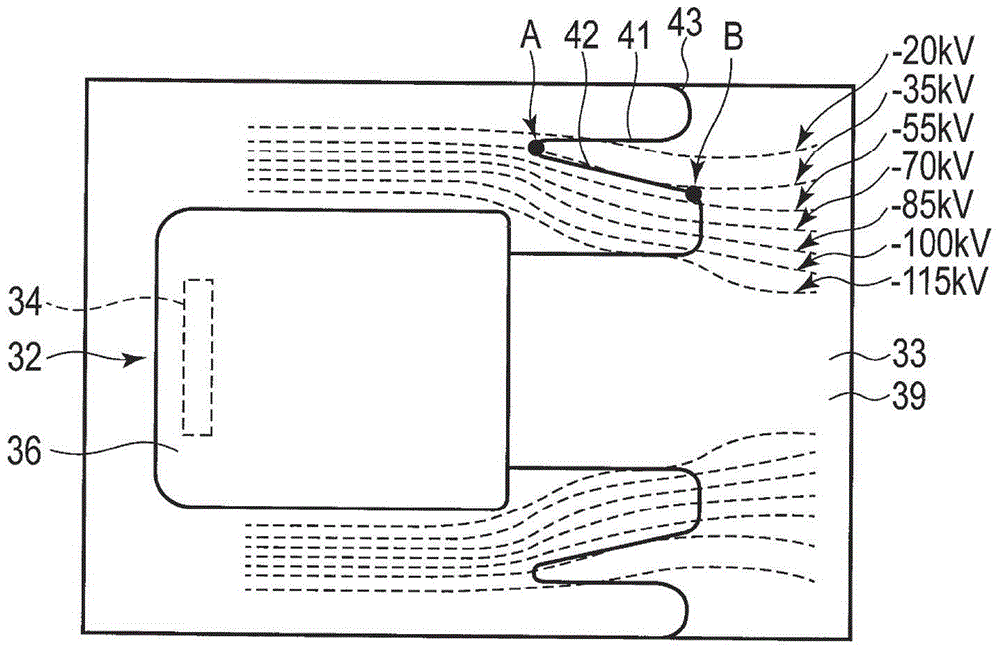

[0017] According to an embodiment, an X-ray tube according to the present invention includes: a vacuum envelope; and an anode and a cathode structure disposed opposite to each other within the vacuum envelope. The cathode structure includes: a cathode; and an insulator that supports the cathode and is installed in the vacuum envelope. The insulator has: a base attached to the vacuum envelope; a supporting portion protruding from the base to support the cathode at its tip; and a cylindrical protrusion protruding from the base and facing the periphery of the supporting portion. .

[0018] Below, refer to Figures 1 to 8B Embodiments will be described.

[0019] figure 2 An X-ray tube device 10 is shown. The X-ray tube device 10 includes: a casing 11 ; and an X-ray tube 12 arranged in the casing 11 . The X-ray tube 12 is an anode-grounded type X-ray tube and is a rotating anode type X-ray tube. The anode potential is ground potential. The space between the housing 11 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com