Single-module drive circuit for multiple pulsed lamps

A technology for driving circuits and pulse lamps, which is applied to electric light sources, electrical components, light sources, etc., can solve the problems of high procurement cost, increased cost, and large actual usage of drive circuit modules, and achieves simplified control and maintenance costs and reduced production. and cost of use, ease of use and assembly, and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings.

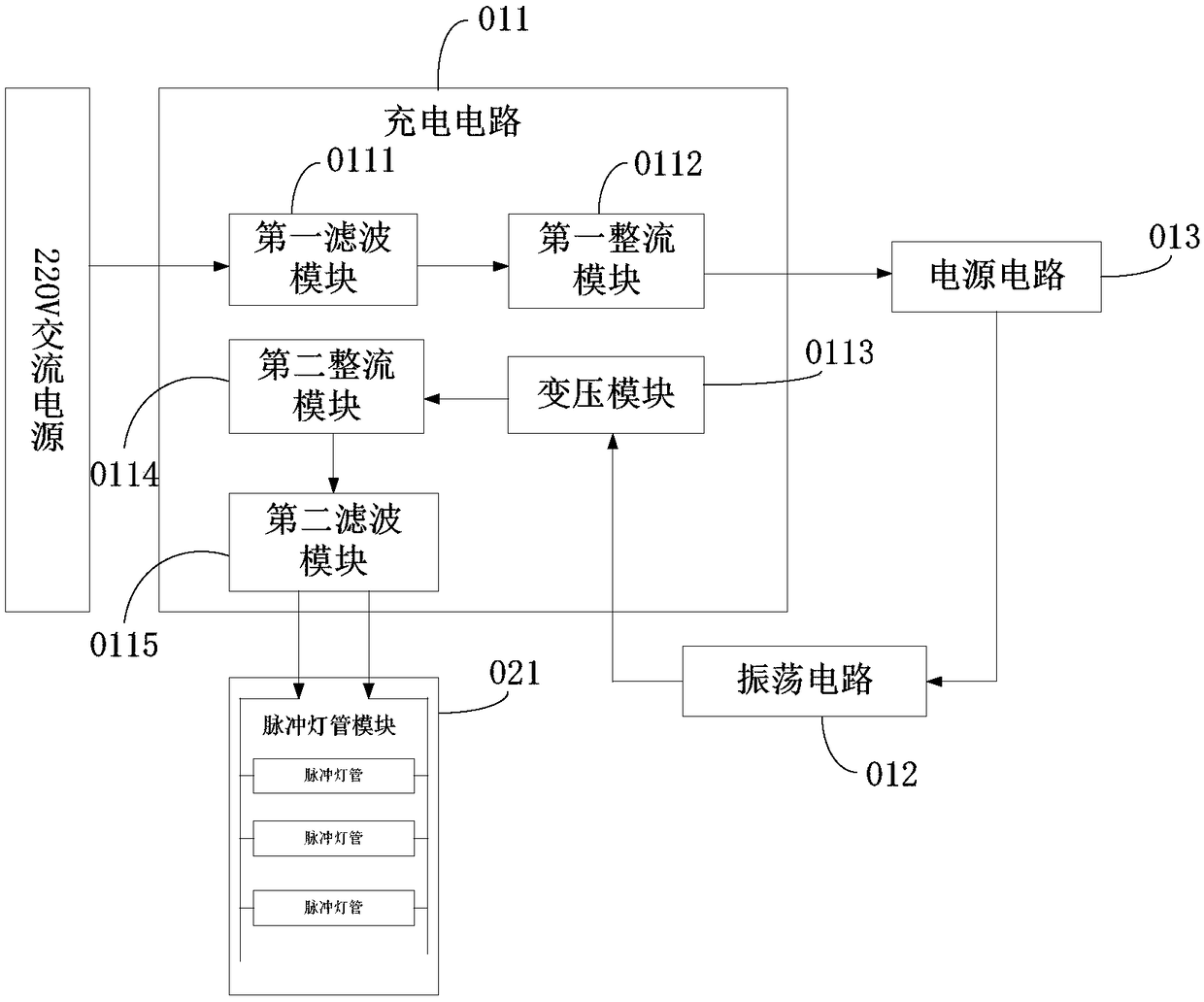

[0042] Such as figure 1 As shown, this solution includes a charging circuit 011, an oscillation circuit 012, and a power supply circuit 013; wherein, the charging circuit 011 includes a first filtering module 0111, a first rectifying module 0112, a transformer module 0113, a second rectifying module 0114, and a second filtering module module 0115;

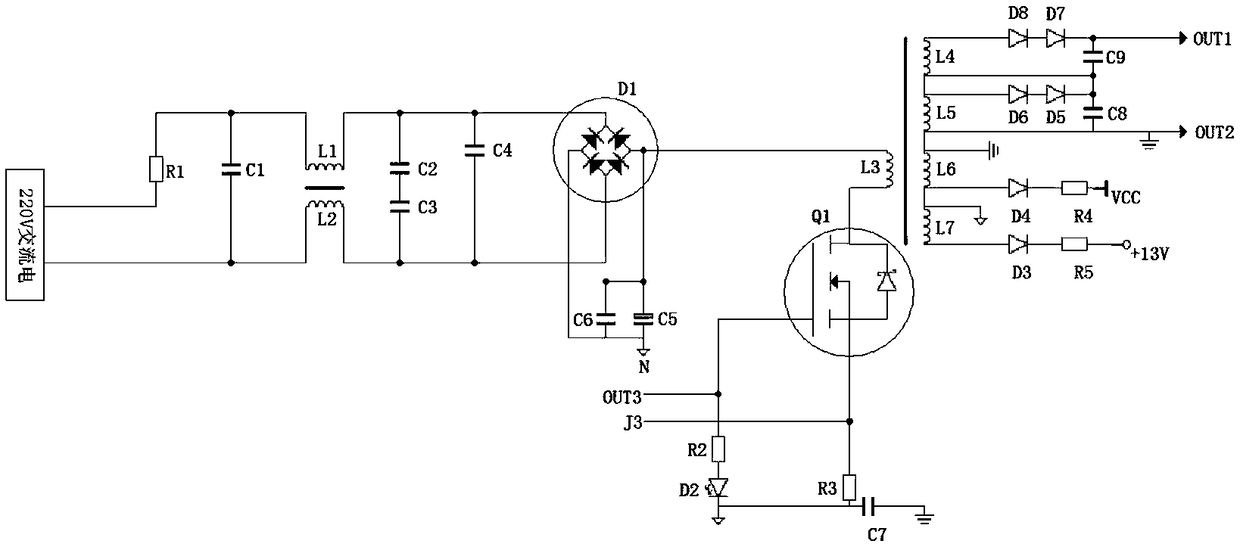

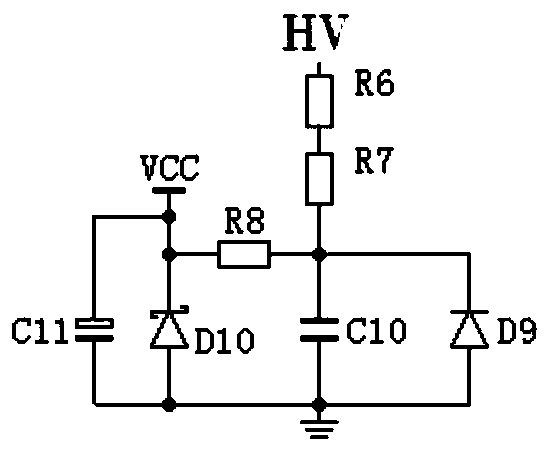

[0043] After the 220V AC power is filtered and rectified by the first filter module 0111 and the first rectifier module 0112, a stable DC signal is output; the DC signal then passes through the joint action of the power supply circuit 013 and the oscillation circuit 012 to output a high frequency The pulse voltage signal is boosted by the transformer module 0113 to generate a high-voltage and high-frequency pulse voltage signal, and the high-frequency and high-voltage pulse voltage signal is rectified and filtered by the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com