Integrated high-rotation-speed swash-plate-rotating motor pump

A motor pump and rotary technology, which is applied in the direction of liquid variable displacement machinery, variable displacement pump components, liquid fuel engines, etc., can solve the problems of increased possibility of overturning of moving parts, low power factor and power density, and unreliable reliability. Improvement and other issues to achieve the effect of improving fault tolerance and reliability, reducing the difficulty of processing and assembly processes, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

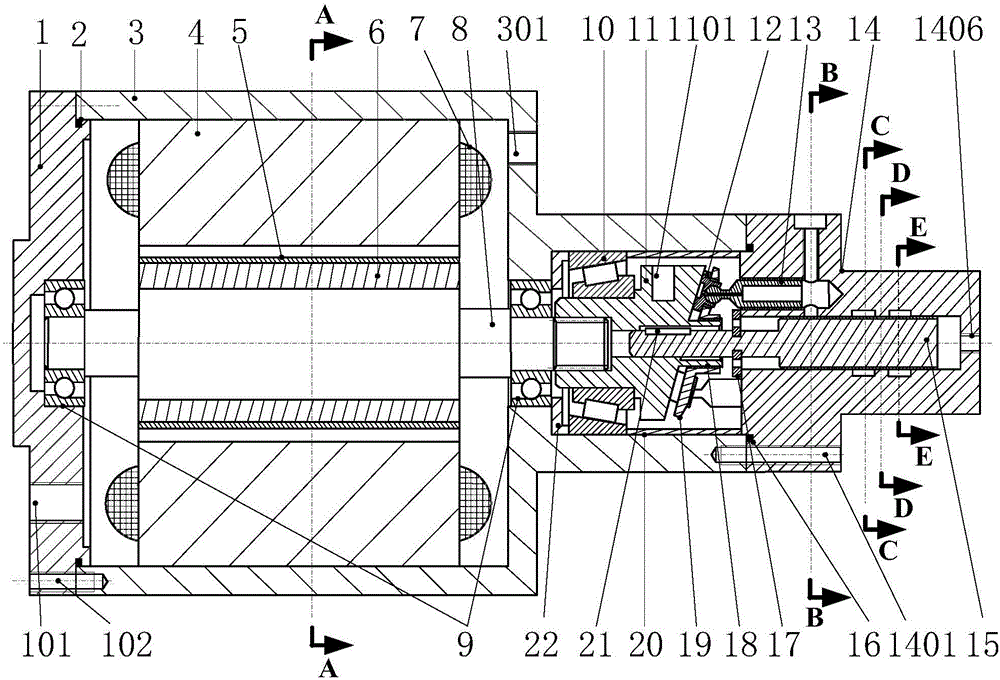

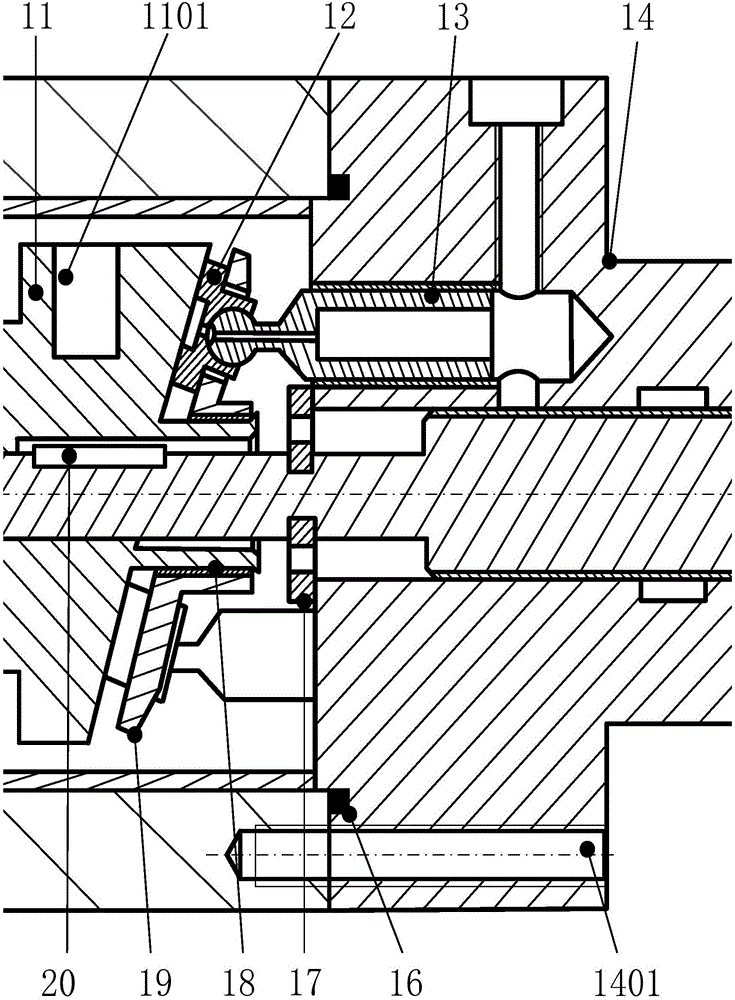

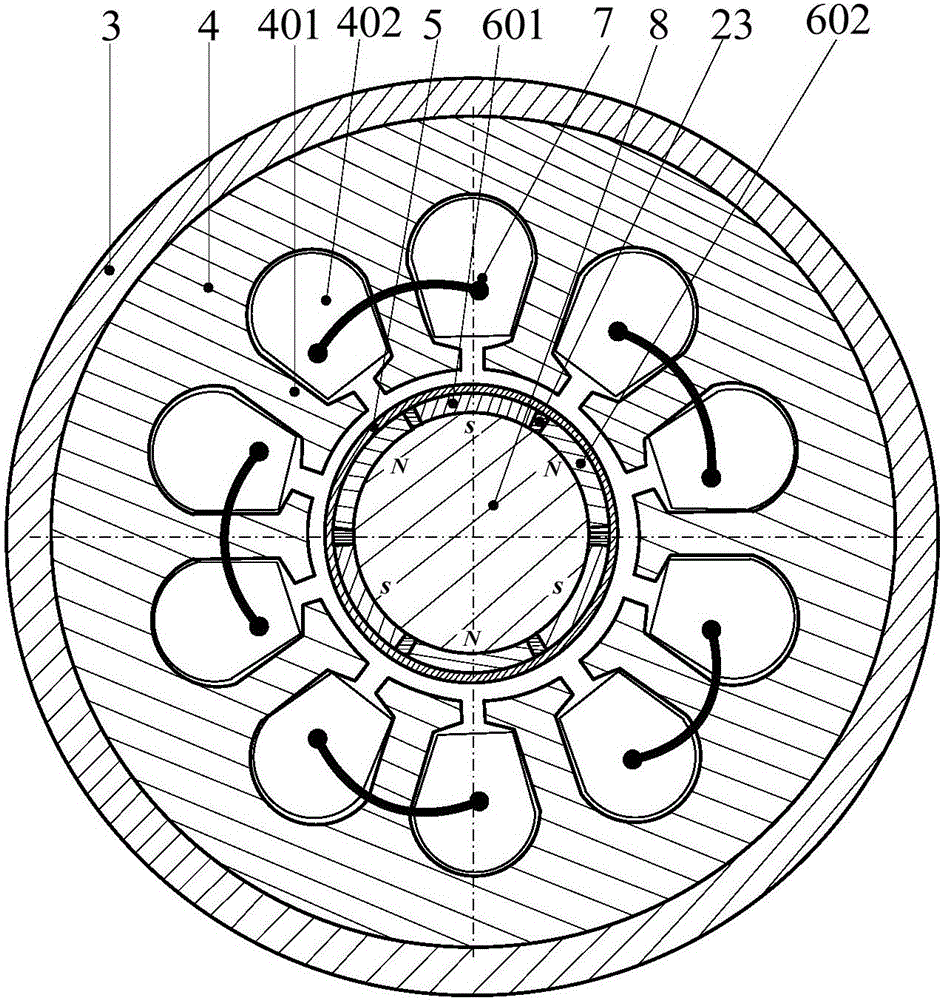

[0042] Attached below Figure 1 to Figure 9 The present invention will be further described with specific examples.

[0043] Such as figure 1 As shown, the present invention includes a motor pump housing 3 and a motor and a swash plate 11 integrally installed in the motor pump housing 3. The motor pump housing 3 is a structure connected by a large end housing and a small end housing. The end face of the end shell is installed with the end cover 1 through the threaded hole 102, and is sealed by the first sealing ring 2; the end face of the small end shell is installed with the rear pump body 14 through the threaded hole 1401, and is sealed by the second sealing ring 16; The large-end housing and the small-end housing are respectively provided with a large-end cavity and a small-end cavity. The large-end cavity and the small-end cavity are connected. A motor is installed in the large-end cavity, and a swash plate mechanism is installed in the small-end cavity. The motor and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com