Anti-substrate deformation structure

A substrate deformation and substrate technology, applied in the direction of electrical connection of printed components, printed circuit components, printed circuits connected to non-printed electrical components, etc. Achieve the effect of suppressing the deformation of the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

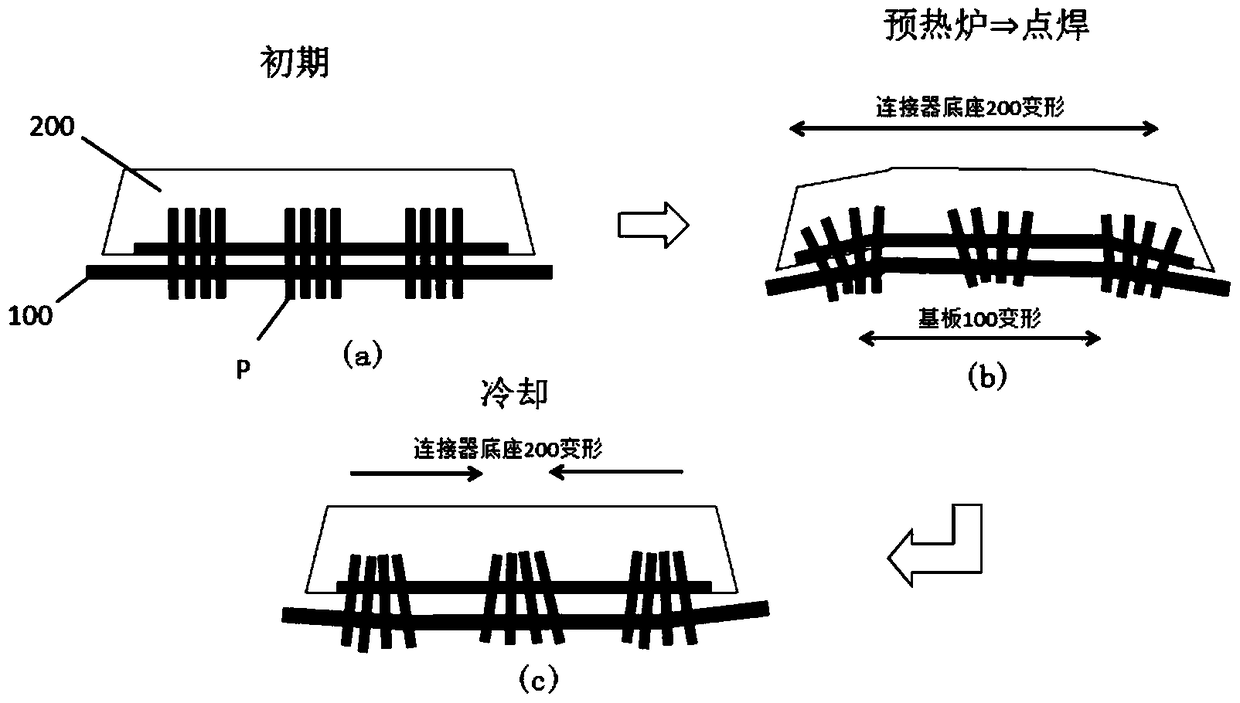

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

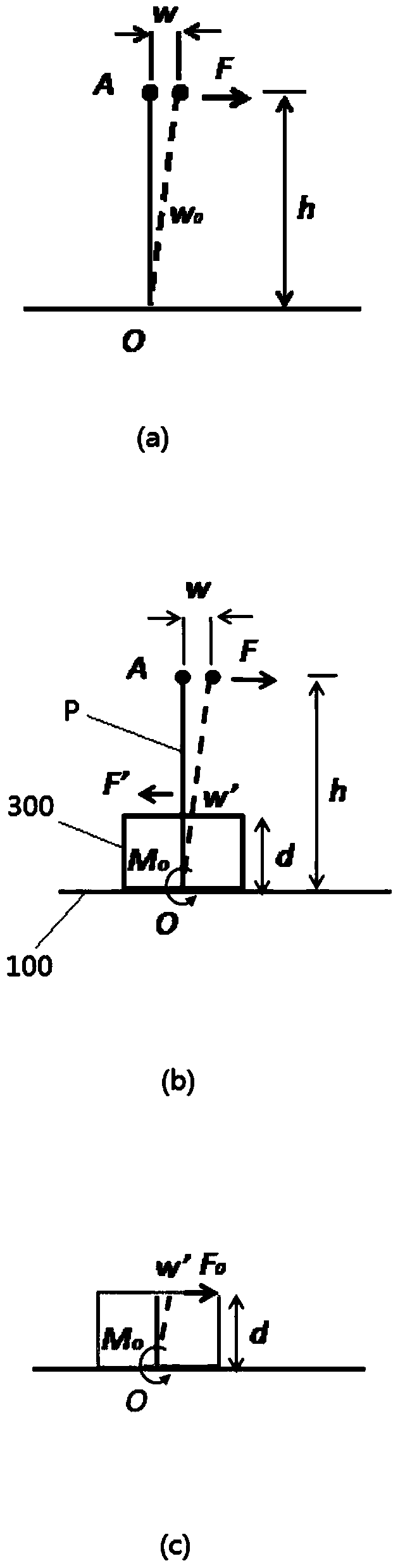

[0021] Below, refer to Figure 2 to Figure 5 , the substrate connection structure B and the force analysis in the substrate connection structure B according to the embodiment of the present invention will be described.

[0022] like figure 2 As shown in (a), the resin plate 300 is interposed between the substrate 100 and the connector base 200, and the substrate 100, the resin plate 300 and the connector base 200 are connected by 2a rows×2b columns of connector terminals P. Additionally, if Figure 5 As shown in (a), solder paste SP is applied between the resin board 300 and the connector base 200 .

[0023] Suppose the length of the resin plate is 2am, the width is 2bn, and the height is d, then as figure 2 As shown in (b), the length of the substrate 100 , the connector base 200 and the resin board 300 corresponding to a single connector terminal P is m, the width is n, and the height of the resin board 300 is d. In addition, assume that the connection point between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com