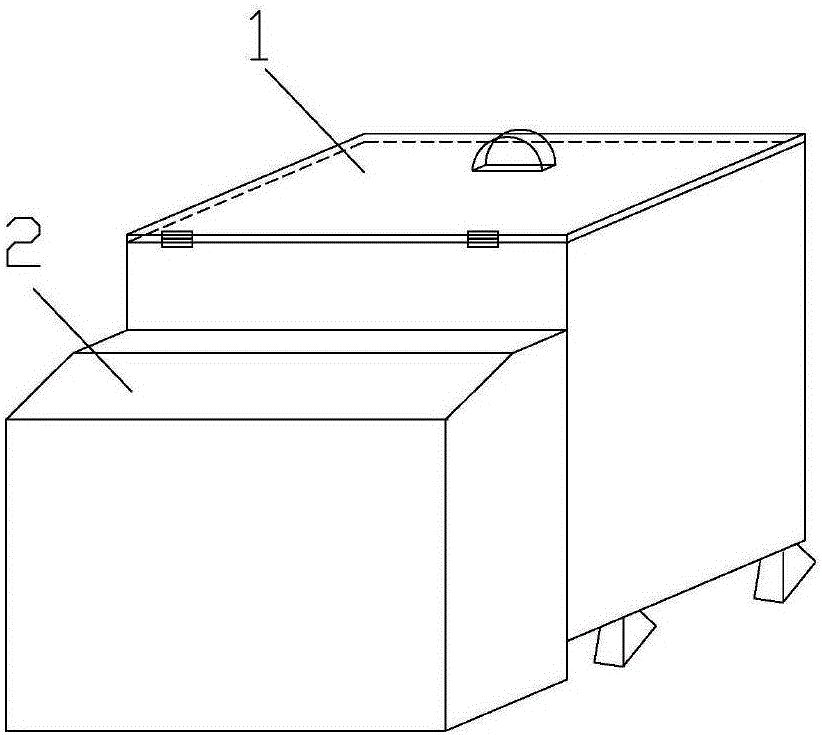

Colostrum pasteurization machine

A technology of pasteurization and disinfection machine, which is applied to the preservation of dairy products, other dairy products, and milk. It can solve the problems of non-adjustable stirring speed, affecting heat utilization effect, and insufficient stirring, so as to avoid scale agglomeration, The effect of shortening the defrosting time and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

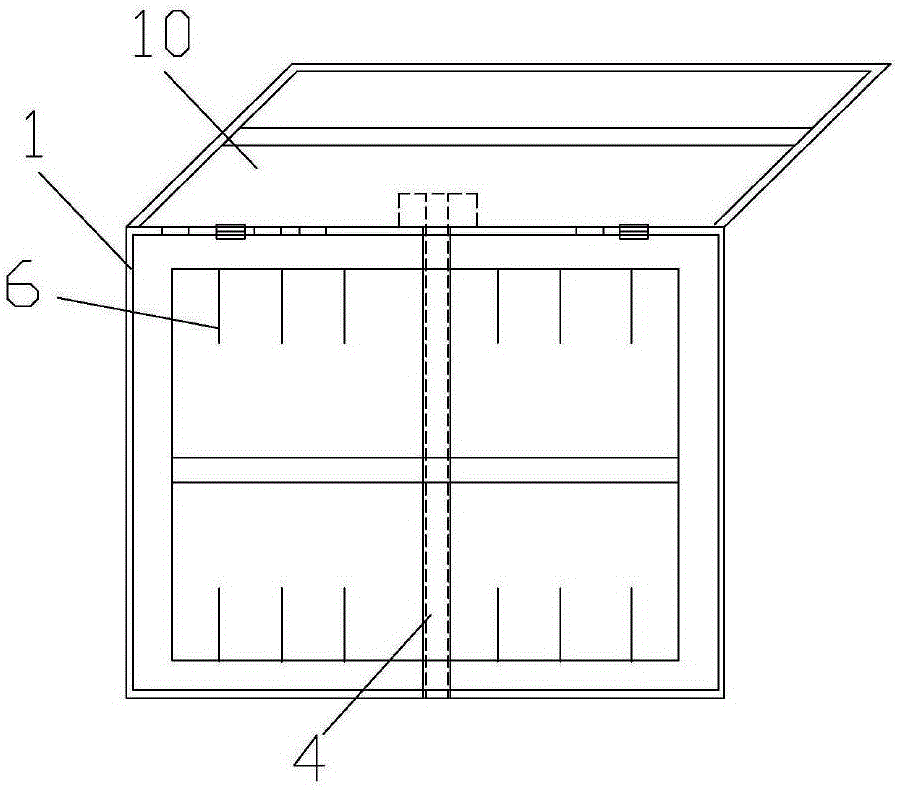

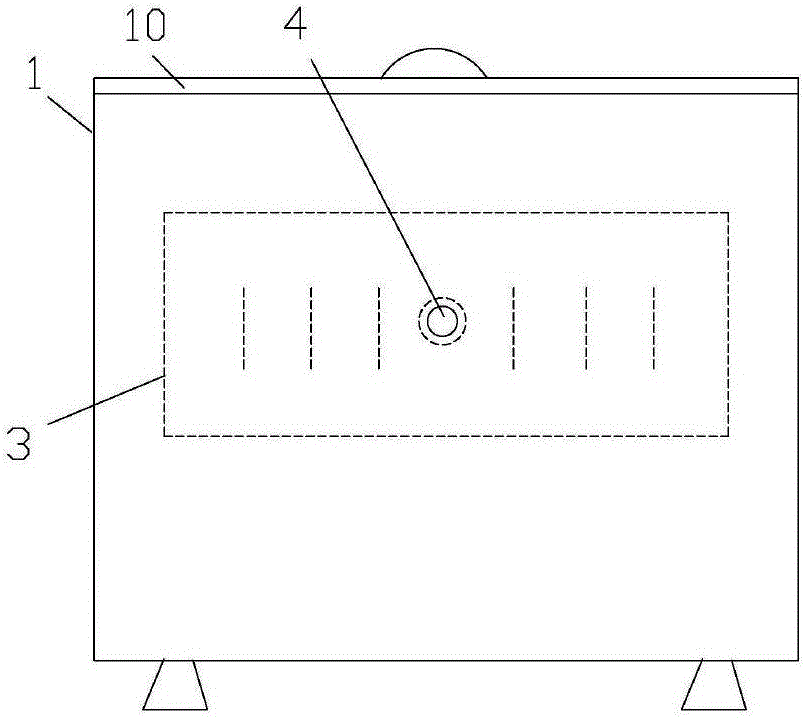

[0045] Embodiment: after the pasture newborn calf is born, need to carry out the supply of 4L colostrum within 12 hours, before carrying out colostrum feeding, the colostrum bag of freezing is taken out from refrigerated place and puts into the thawing basket, opens the bar Then the thawing basket is stuck in the clamping part formed by the adjacent fixed basket clips 6. Twelve fixed basket clips 6 form eight clamping parts in total, so it can be put into eight bags at a time. breast bag. After putting away, the case cover 10 is closed, and the heating device and the circulating water device are filled with water. Since the circulating water in the plate heat exchanger 9 is connected to the pasteurization case 1, the pasteurization case 1 is also in the same time. Filled with water, the water level exceeds the top contour line of rotating drum 3. At this time, start two electric heating rods to heat the water in the two heating tanks 11 at the same time, and then the first wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com