Gulfweed-cuttlefish sausages and making method thereof

A technology of sargassum and cuttlefish, which is applied in food science and other directions, can solve the problems of more loss of nutrients, limited consumer groups, and loss of water in products, and achieves low economic value, reduces residues, and improves food and economic value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

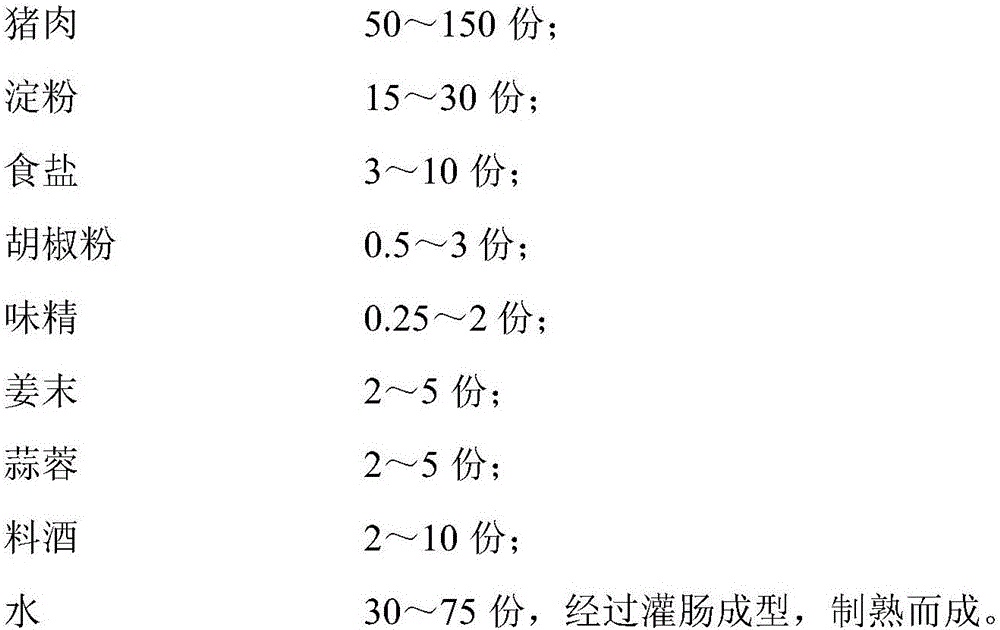

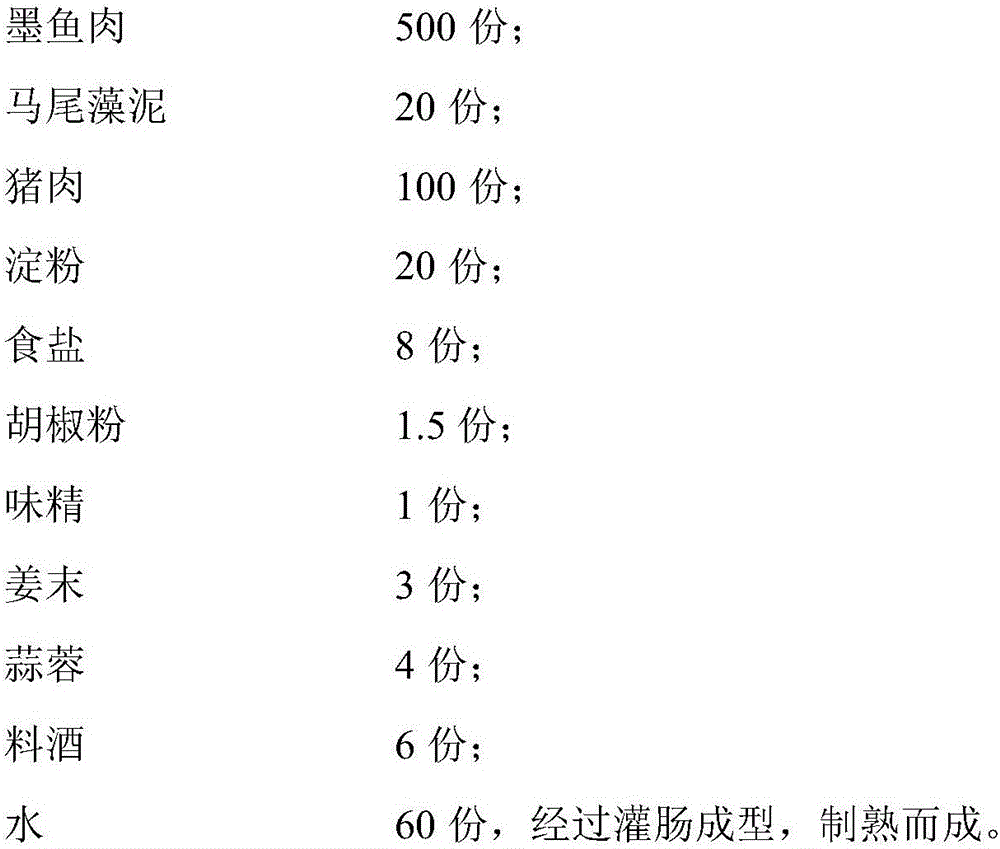

Image

Examples

Embodiment 1

[0030] According to Table 1, prepare the required weight parts of each composition. Specifically, the preparation method of Sargassum cuttlefish sausage includes the following steps:

[0031] S1. Raw material pretreatment

[0032] S11. Pretreatment of cuttlefish meat: Put the cleaned cuttlefish meat into a masher and smash it, then stir the minced cuttlefish meat for 2 minutes, then add salt and continue stirring for 1 minute to obtain minced cuttlefish meat for use;

[0033] S12. Pretreatment of pork: take the diced pork cut from fresh pork, put it into a meat grinder and chop it for later use;

[0034] S2. Mixing: First add the pork obtained in step S12 to the minced cuttlefish obtained in step S11 and stir for 5 minutes, then add other components except the sargasso mud and continue to stir for 3 minutes, and finally add the sargasso mud and stir for 5 minutes. Proceed in the same direction to get the semi-finished sargassum cuttlefish sausage;

[0035] S3. Enema molding and cooking...

Embodiment 2~6

[0038] The difference between Examples 2 to 6 and Example 1 is that the required parts by weight of the components are prepared according to the distribution ratio of each group specified in Table 1, and the other conditions are the same. The sensory evaluation results are shown in Table 3.

Embodiment 7

[0040] Different from Example 1, the Sargassum cuttlefish sausage was prepared as follows:

[0041] S1. Raw material pretreatment

[0042] S11. Pretreatment of cuttlefish meat: Put the cleaned cuttlefish meat into a masher and smash it, then stir the minced cuttlefish meat for 2 minutes, then add salt and continue stirring for 1 minute to obtain minced cuttlefish meat for use;

[0043] S12. Pretreatment of pork: take the diced pork cut from fresh pork, put it into a meat grinder and chop it for later use;

[0044] S2. Mixing: First add the pork obtained in step S12 to the minced cuttlefish obtained in step S11 and stir for 3 minutes, then add other components except the sargasso mud and continue to stir for 3 minutes, and finally add the sargasso mud and stir for 3 minutes. Proceed in the same direction to get the semi-finished sargassum cuttlefish sausage;

[0045] S3. Enema molding and cooking: The semi-finished sargassum cuttlefish sausage obtained in step S2 is subjected to enema a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com