A kind of anatomical bone plate of coronoid process of ulna

A coronoid process and bone plate technology, applied in the field of ulna coronoid anatomical bone plate, can solve the problems of increasing the exposure range of the incision, no anatomical plasticity, easy to fail, etc., to increase the flexibility of the fixation, improve the treatment effect, and facilitate the postoperative Restoration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

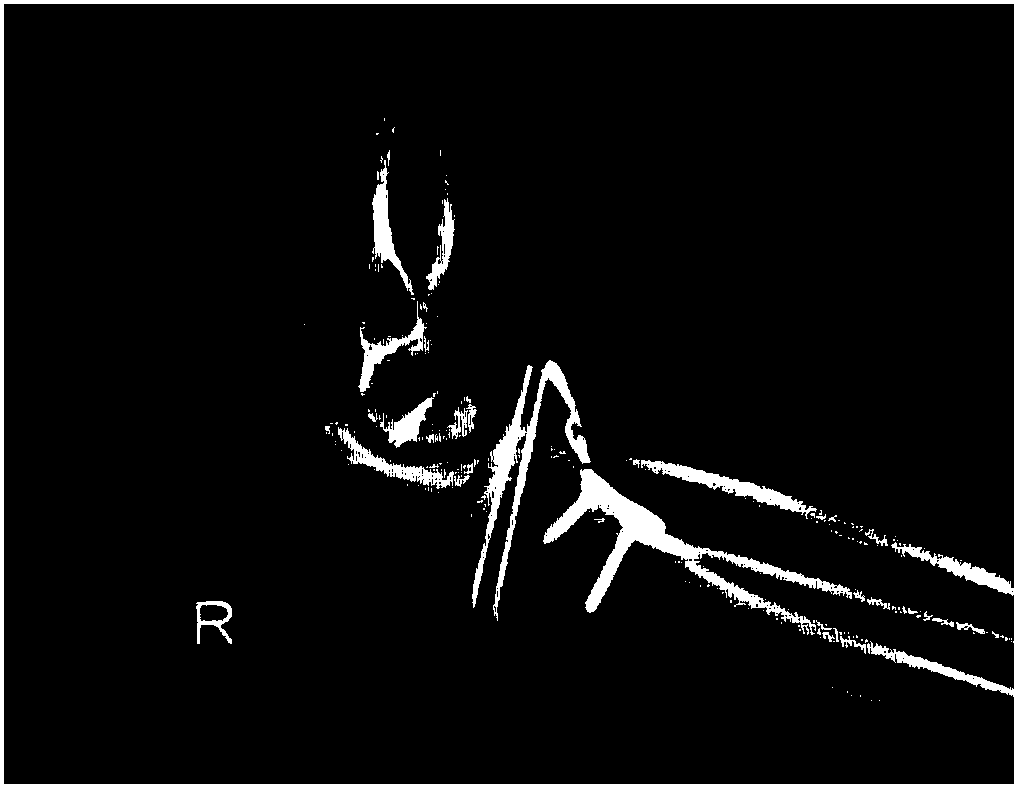

[0041] Image measurement of anatomical bone plate in coronoid process of ulna

[0042] The imaging center of Shandong University Qilu Hospital (Qingdao) selected 44 cases of normal elbow joint CT reconstruction films for imaging measurement, and measured the height, length, projective distance, curvature, width, and tangent clip of the coronoid process and the olecranon olecranon. Angles are listed in Table 1, and the average value is calculated. Among them, the CT machine used in the measurement is produced by Philips in the Netherlands, and the computerized tomography (CT) model is Brilliance64-slice.

[0043] Table 1 The image measurement data of the anatomical bone plate of the ulnar coronoid process

[0044]

[0045]

[0046] In the data given in Table 1, the average value is calculated after removing the maximum and minimum values under each data item, which can reduce the error and make the calculated data more accurate. Combined with the above The parameters ...

Embodiment 2

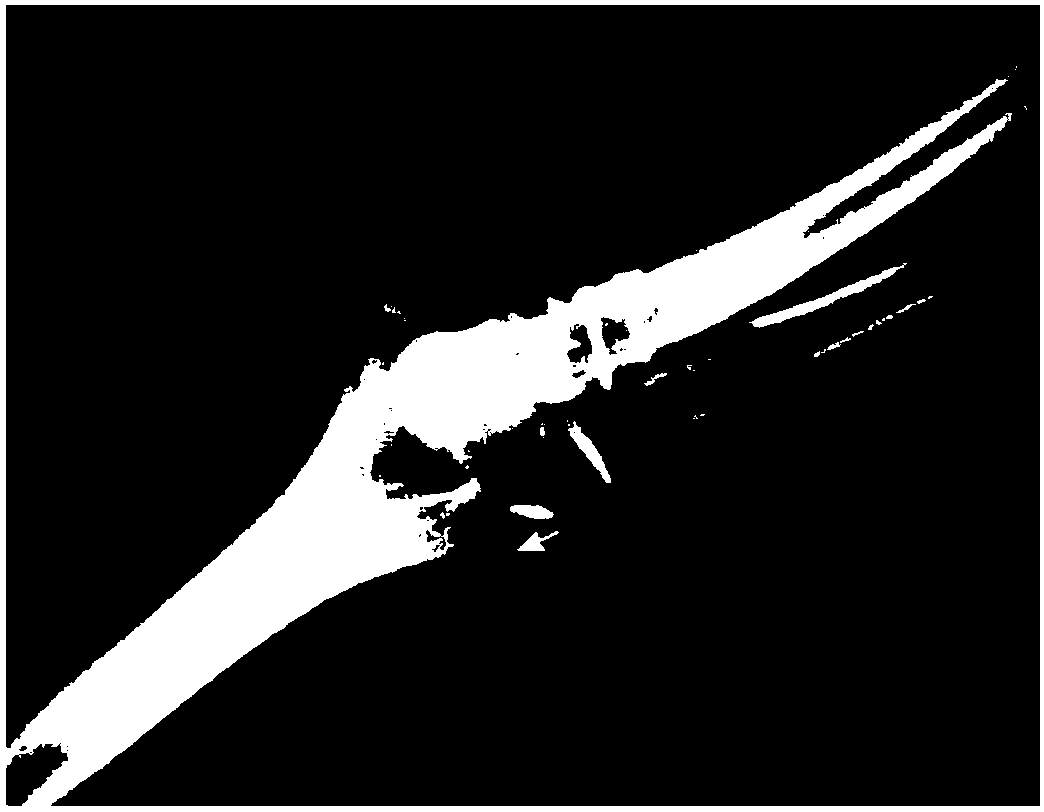

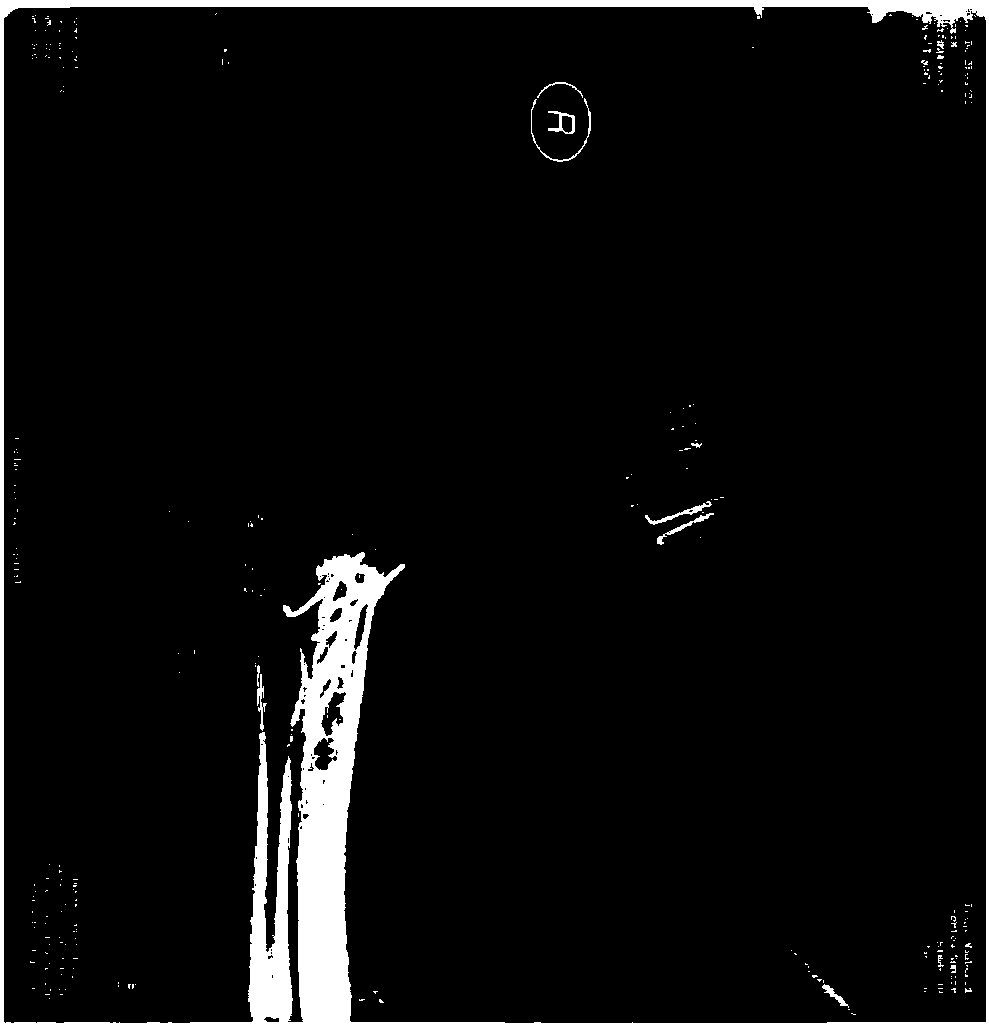

[0048] Ulnar coronoid dissection plate use

[0049] Such as Figure 4-6 As shown, the ulna coronoid anatomical bone plate includes a steel plate body 1 with a curved radian, and the curved arc of the steel plate body 1 is 44°. The steel plate body 1 includes a head and a handle, and the head and the handle are integrally connected, and its length is 52mm , with a height of 22 mm and a thickness of 1.5 mm. The width of the head is greater than that of the handle, and the width gradually decreases from the front end of the head to the tail end of the handle to match the anatomical shape of the anteromedial column of the ulna coronoid. The head is provided with a first locking hole 2, and a near row of steel needle holes 6 is also arranged between the first locking hole 2 and the front end of the head, wherein the head includes a set of holes for pre-setting the bone block in sequence near the front end. The fixed proximal row of steel needle holes 6 and the first locking hole 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com