Ultrahigh-speed magnetic suspension solid-liquid separation device

A solid-liquid separation and magnetic levitation technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve the problems of polluted solution, low separation speed and high cost, and achieve the effect of saving cost, avoiding replacement and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

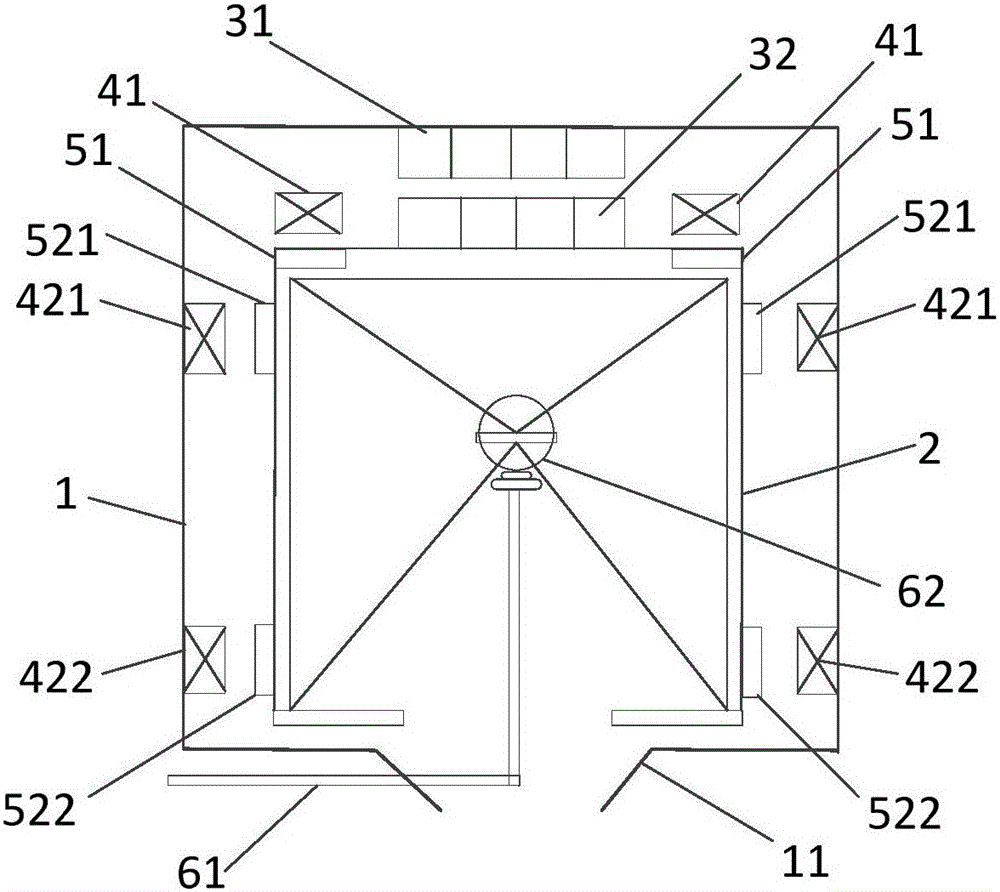

[0024] like figure 1 As shown, this embodiment provides an ultra-high-speed magnetic levitation solid-liquid separation device, including a housing 1, a disc motor, a rotating chamber 2, an axial electromagnetic coil 41, a side electromagnetic coil, a top permanent magnet 51, a side permanent magnet, and a nozzle Connect shaft 61 and nozzle 62 and other components. The side electromagnetic coil includes an upper electromagnetic coil 421 and a lower electromagnetic coil 422 , the side permanent magnet includes an upper permanent magnet 521 and a lower permanent magnet 522 , and the disc motor adopts an axial magnetic field disc switched reluctance motor. The top permanent magnet 51 , the upper permanent magnet 521 and the lower permanent magnet 522 are made of magnetic steel material. The housing 1 includes a top plate, a side plate and a bottom plate. The top plate is fixedly connected to the side plates, and the bottom plate is movably connected to the side plates, so that c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com