Bio-membrane reactor realizing synchronous nitrification, denitrification and anaerobic ammoxidation and fast realization method

A biofilm reactor and anaerobic ammonium oxidation technology, which is applied in chemical instruments and methods, biological water/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem of long generation cycle of anammox bacteria and difficult Coupled with problems such as synchronous use and slow growth, to achieve the effects of partitioned growth, shortened start-up time, and high mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

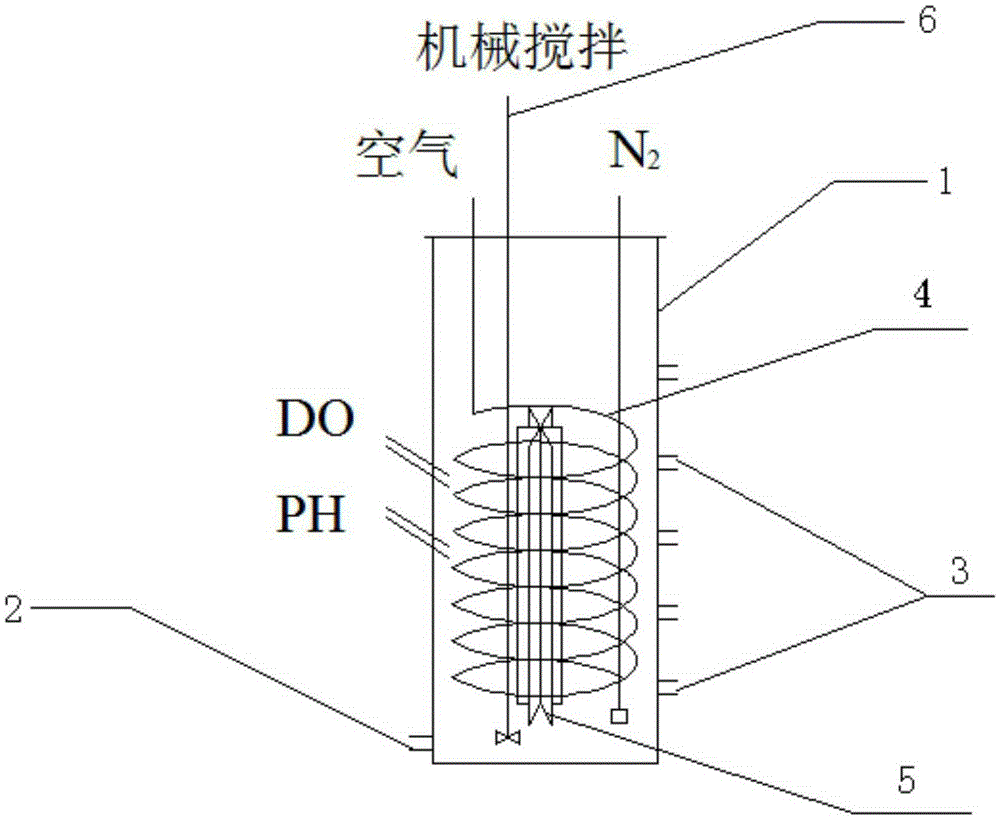

[0048] A biofilm reactor for synchronous nitrification-denitrification-anammox, with a structure such as figure 1 As shown, including a reactor body 1, an online dissolved oxygen meter and a pH meter, the reactor body is a vertical cylinder, and a water inlet 2 is provided at the bottom of the side wall of the reactor body, and a water outlet 3 is provided at the top. A spiral hollow fiber membrane tube 4 is arranged inside the reactor body, and the hollow fiber membrane tube 4 extends from the upper part of the reactor body to the lower part along the central axis of the reactor body. The diameter of the hollow fiber membrane tube 4 is 1mm, and the length is 8m. The membrane pore diameter on the tube wall is 0.1um, and the helical pitch of the helical hollow fiber membrane tube 4 is 6cm. In the space surrounded by the hollow fiber membrane tube spiral, a non-woven filler 5 is provided. The non-woven filler 5 includes 6 dendritic strip-shaped non-woven sheets connected togethe...

Embodiment 2

[0050] Utilize the biofilm reactor of embodiment 1 to realize the method for synchronous nitrification-denitrification-ANAMMOX, comprising steps as follows:

[0051] (1) Add 3L of activated sludge into the membrane aerated biofilm reactor, the effective volume of the membrane aerated biofilm reactor is 10L; the activated sludge is discharged from a municipal sewage treatment plant in Jinan City Sludge, through filtering and screening to remove impurities such as leaves, waste paper, waste plastics, etc. in the sludge, and then add the sludge to the reaction zone of the membrane aerated biofilm reactor, and use a peristaltic pump from the bottom of the reactor to Enter the waste water to be treated, so that the hydraulic retention time of the sewage to be treated in the reactor is 24 hours, and remove the floating and expanding sludge. After the membrane aerated biofilm reactor has been running for 7 days, the sedimented sludge at the bottom is collected as activated sludge.

...

Embodiment 3

[0057] Utilize the biofilm reactor of embodiment 1 to realize the method for synchronous nitrification-denitrification-ANAMMOX, comprising steps as follows:

[0058] (1) Add 3L of anaerobic granular sludge into the membrane aerated biofilm reactor, the effective volume of the membrane aerated biofilm reactor is 10L; the anaerobic granular sludge is taken from the wastewater treatment of a paper mill in Zibo The sludge discharged from the factory is filtered and screened to remove impurities such as leaves, waste paper, and waste plastics in the sludge, and then the sludge is added to the reactor, and the wastewater to be treated is fed from the bottom of the reactor with a peristaltic pump. The hydraulic retention time of the sewage to be treated in the reactor is 24 hours, and the floating and expanding sludge is removed. After the membrane aerated biofilm reactor has been operated for 7 days, the sedimented sludge at the bottom is collected as activated sludge.

[0059] (2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com