An Intelligent Robot Welding System

A robot welding and welding assembly technology, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., to achieve the effects of assembly inspection before welding, real-time control of weld quality, and prevention of welding deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

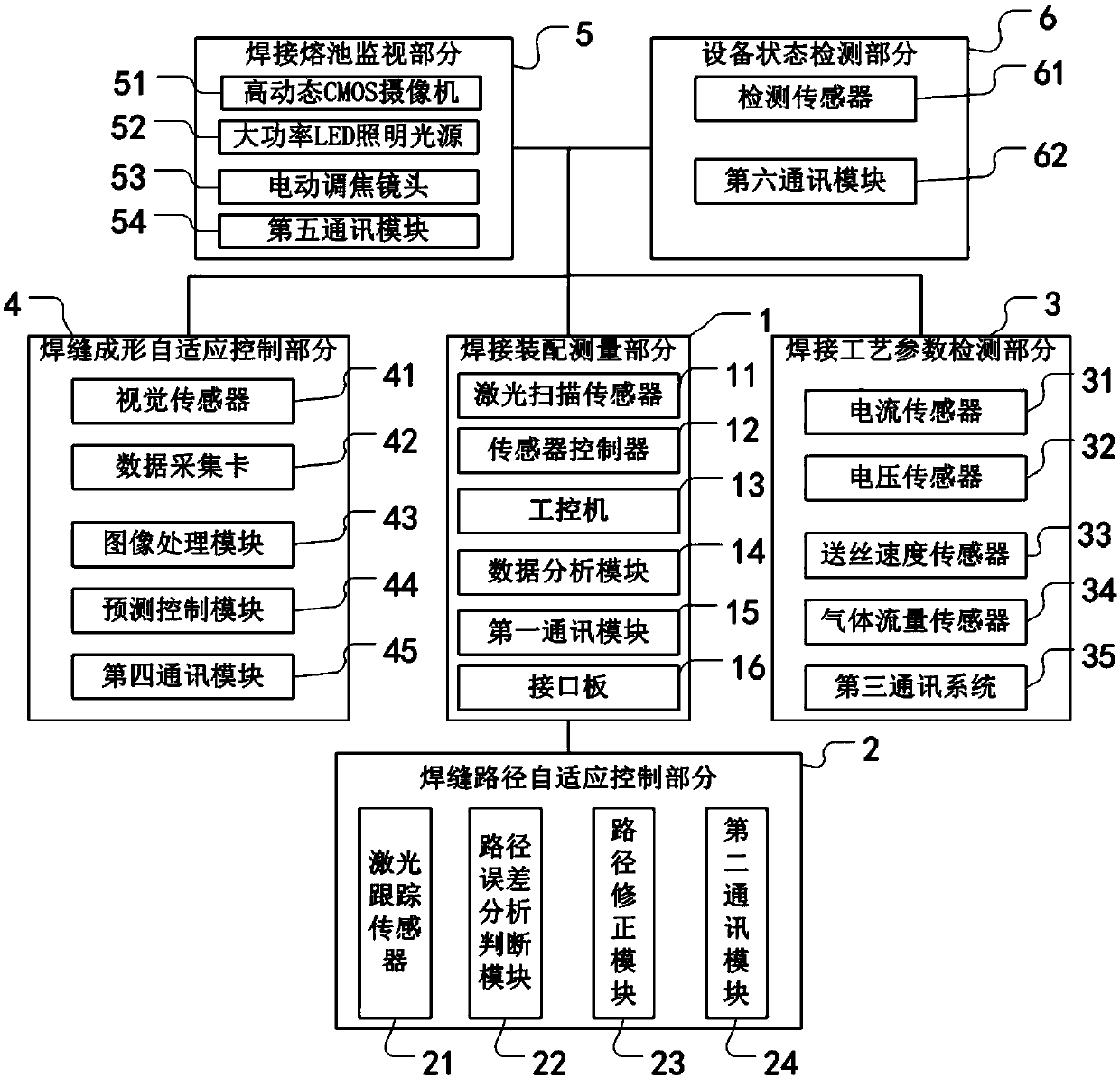

[0065] Examples such as figure 1 As shown, an intelligent robot welding system includes a welding assembly measurement part 1, a weld path adaptive control part 2, a welding process parameter detection part 3, a weld shape adaptive control part 4, a welding melt A pool monitoring section 5 and an equipment status detecting section 6.

[0066] Wherein, the welding assembly measurement part 1 is used for high-precision on-line detection and analysis of parameters or information of the welding assembly in the welding environment, so as to realize pre-welding assembly detection.

[0067] Specifically, the welding assembly measurement part 1 includes a laser scanning sensor 11 , a sensor controller 12 , an industrial computer 13 , a data analysis module 14 , a first communication module 15 and an interface board 16 and so on.

[0068] The laser scanning sensor 11 is used to scan and weld the area and obtain and upload various parameters or information of the welding area, includin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com