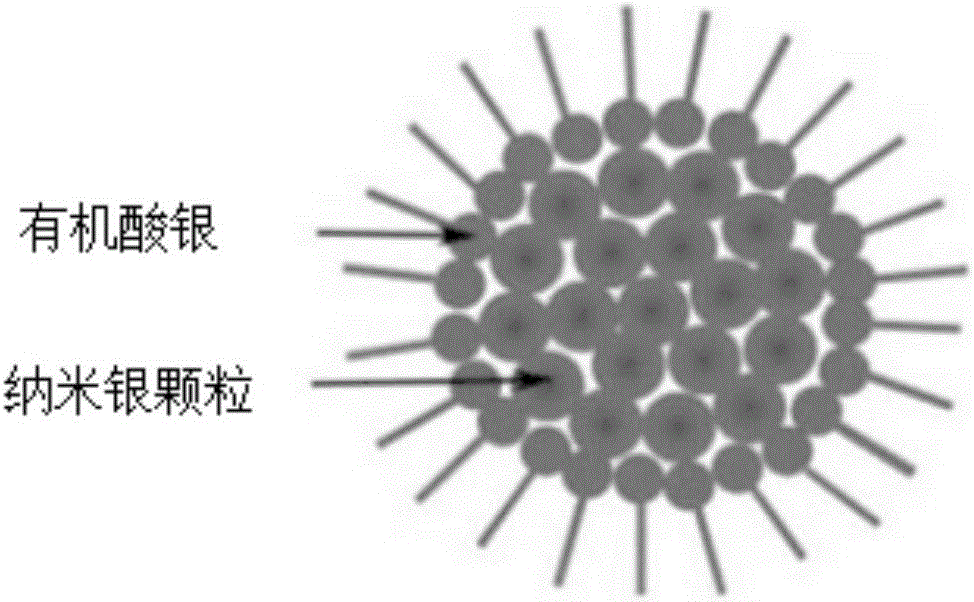

Silver nano-particle coated by organic acid silver, method for preparing silver nano-particle and application thereof

A technology of nano-silver particles and organic acid silver, which is applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of agglomeration and large particle size, and achieve the effects of simple operation, broad industrial application prospects, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Using lauric acid etc. as raw materials to prepare organic acid silver-coated nano-silver particles, the specific steps are as follows:

[0030] (1) Mix 0.015 mol of NaOH, 0.016 mol of lauric acid and 600 ml of deionized water, and heat to 80°C, then add 0.015 mol of silver nitrate, stir for 1.5 hours, let stand and separate layers, take out the upper layer of white The waxy substance is silver laurate with a small amount of impurities;

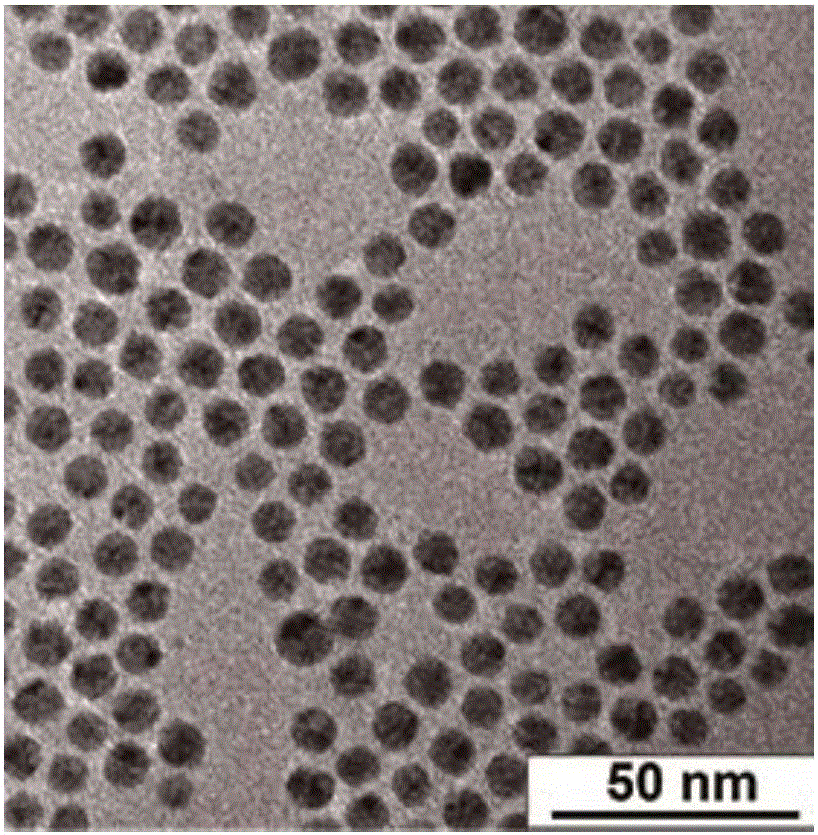

[0031] (2) Centrifuge the white waxy substance in the above step (1) for 3 times and 1 time respectively with deionized water and alcohol, the centrifugal rate is 7000r / min, and the cleaning time is 10min each time, the purpose is to remove impurities; then It was dried at a temperature of 80° C., and the drying time was 6 hours; finally, it was heated to 250° C. in nitrogen and kept at a temperature of 90 minutes to obtain powdered silver laurate-coated silver nanoparticles.

[0032] figure 2 It is the TEM photograph of the silver ...

Embodiment 2

[0034] Use ascorbic acid etc. as raw material to prepare organic acid silver-coated nano-silver particles, the specific steps are as follows:

[0035] (1) Mix 0.014 mol of NaOH, 0.015 mol of ascorbic acid and 550 ml of deionized water, and heat to 80°C, then add 0.02 mol of silver nitrate, stir for 1.5 hours, let stand and separate layers, take the upper white The waxy substance is silver ascorbate with a small amount of impurities;

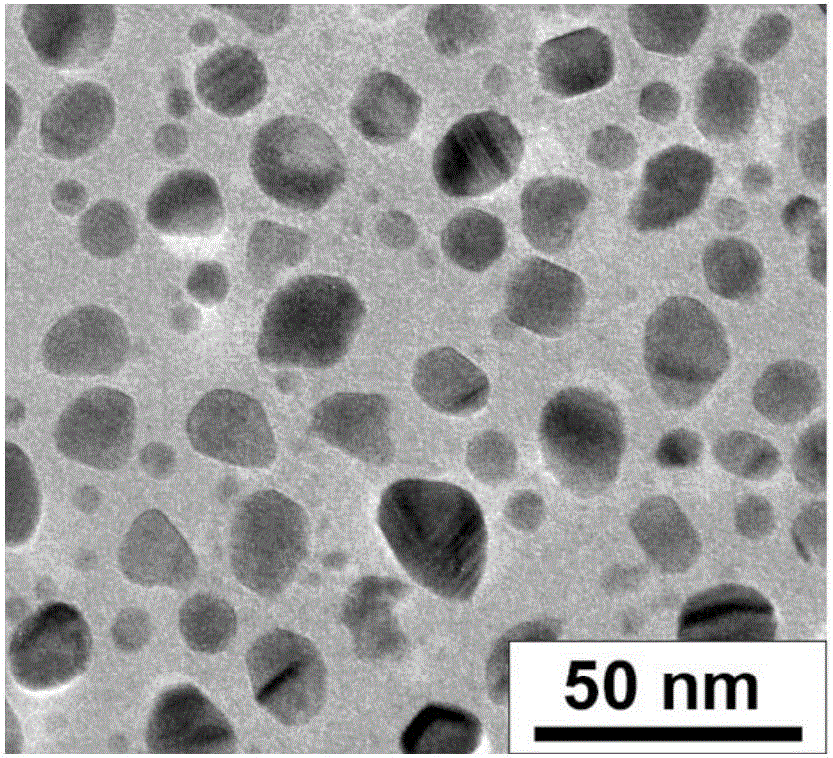

[0036] (2) The white waxy substance in the above step (1) is centrifugally cleaned 4 times and 1 time respectively with deionized water and alcohol, the centrifugal rate is 7000r / min, and the cleaning time is 10min each time, the purpose is to remove impurities; then It was dried at a temperature of 75° C., and the drying time was 8 hours; finally, it was heated to 230° C. in nitrogen and kept at a temperature of 100 minutes to obtain powdered silver ascorbate-coated silver nanoparticles.

[0037] image 3 It is the TEM photo of the silver asco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com