A flexible tooling system for assembly and welding of urban rail car floor and middle roof

A welding flexible and floor technology, which is applied in the field of urban rail car floor and middle roof assembly welding flexible tooling system, can solve the problems of time-consuming and laborious clamping, and achieve the effect of simple structure, fast clamping and reduced manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

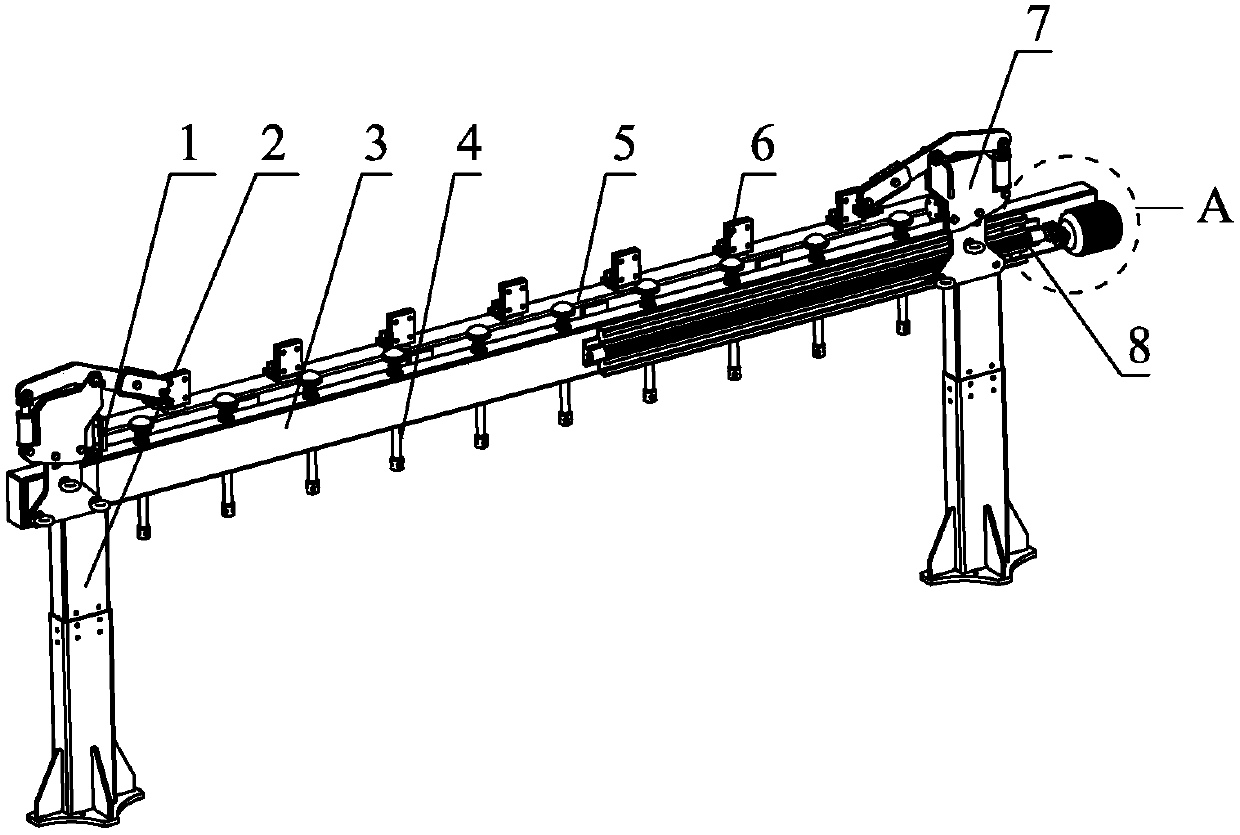

[0029] Embodiment 1 (floor assembly and welding)

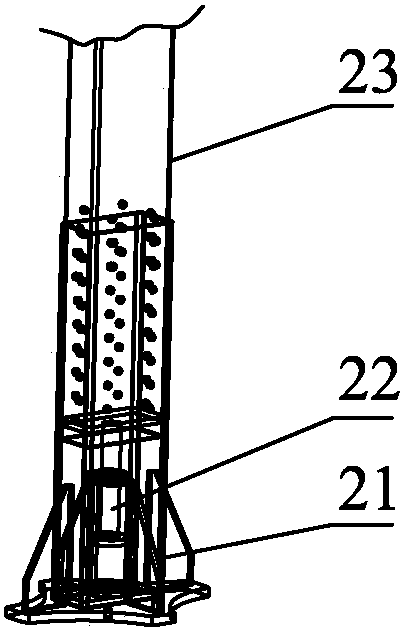

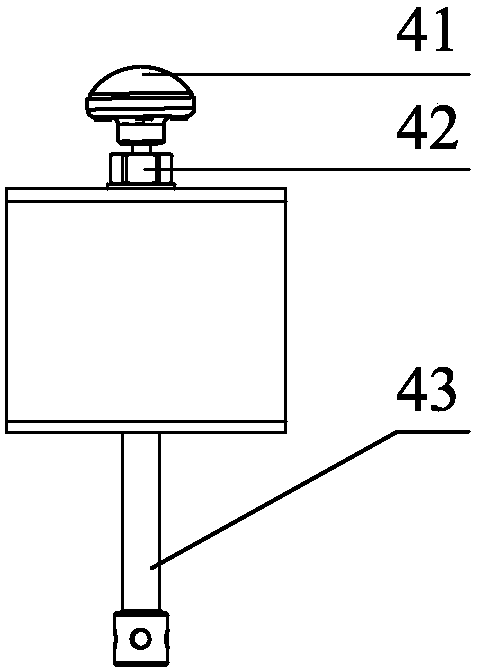

[0030] Such as Image 6 As shown, first, according to the length of the floor, increase the number of tooling units in the longitudinal direction of the floor. After the longitudinal number is determined, then adjust the column 2 of each tooling unit as follows according to the requirements of the operating height and the height of the workers. By controlling the hydraulic cylinder Ⅰ22 Adjust the inner column 23 to expand and contract relative to the outer column 21, so as to drive the beam 3 to a suitable height, only fix the end positioning beam 5 on the beam 3 of the tooling unit at the head end position, and install the end positioning beam 5 on the end positioning beam 5 Module 6. Secondly, place the side positioning module 1 on one end of the beam 3 of all tooling units, the support nail 43 is placed on the beam 3 through the sleeve 42, the plane type is selected for the support head 41, and the horizontal number of the...

Embodiment 2

[0031] Embodiment 2 (middle roof assembly and welding)

[0032]Firstly, increase the number of vertical tooling units on the floor according to the length requirements of the middle roof. After the vertical number is determined, the column 2 of each tooling unit is adjusted as follows according to the requirements of the operating height and the height of the workers. Adjustment is made by controlling the hydraulic cylinder I22 The inner column 23 is stretched relative to the outer column 21, thereby driving the beam 3 to a suitable height, only fixing the end positioning beam 5 on the beam 3 of the tooling unit at the head end position, and installing the end positioning module 6 on the end positioning beam 5 . Secondly, place the side positioning module 1 on one end of the crossbeam 3 of all tooling units, the support nail 43 is placed on the crossbeam 3 through the sleeve 42, the support head 41 selects the curved surface type, and adjusts the horizontal position of the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com