Grinding method and grinding apparatus

A grinding and grinding technology, which is used in grinding drive devices, machine tools designed for grinding workpiece rotating surfaces, metal processing equipment, etc., can solve the problem of reduced compressor performance, increased mechanical loss, compressor wear, etc. problems, to achieve the effect of reducing surface roughness, inhibiting wear or sintering, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0046] [Structure of Cylindrical Grinder 100]

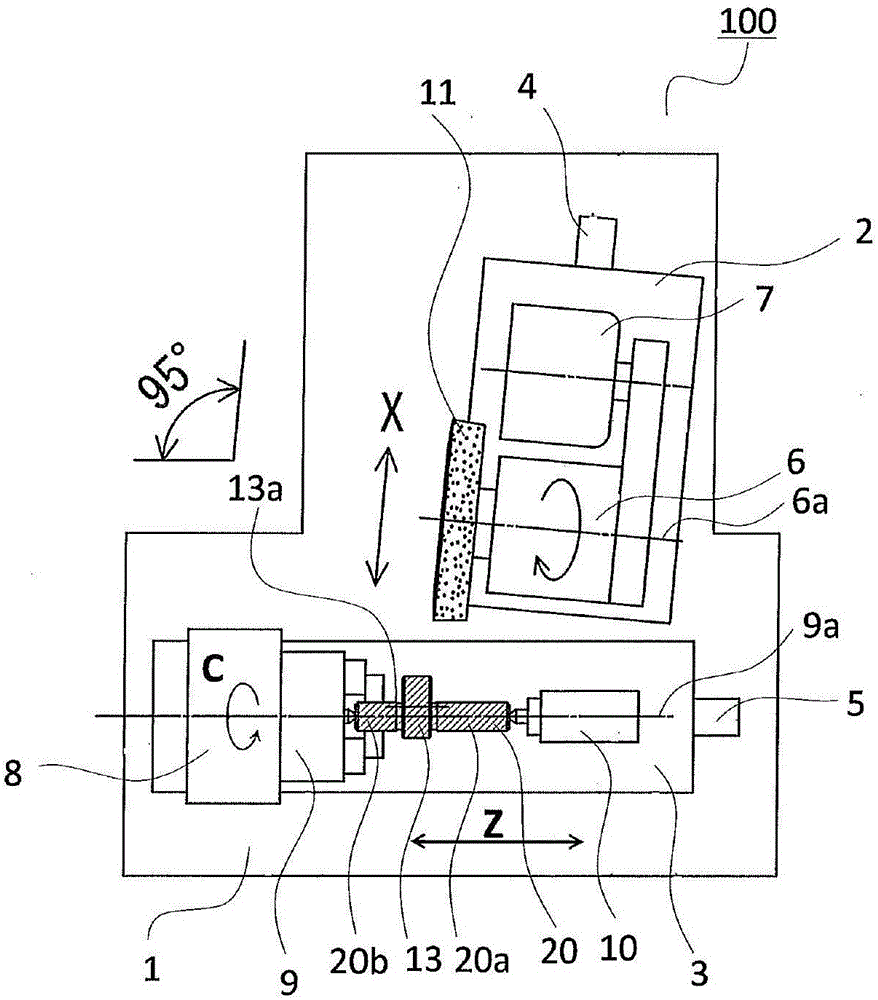

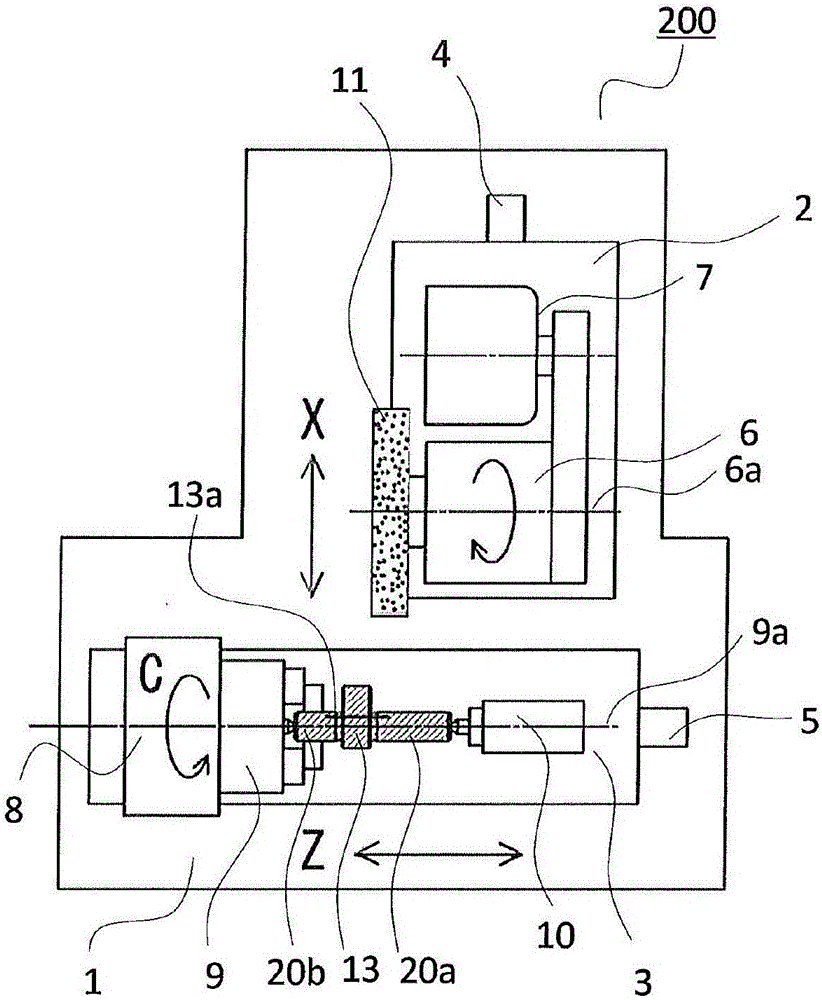

[0047] figure 1 It is a top view showing the structure of the cylindrical grinder 100 which concerns on this embodiment. In addition, the cylindrical grinder 100 corresponds to the "grinding device" of this invention.

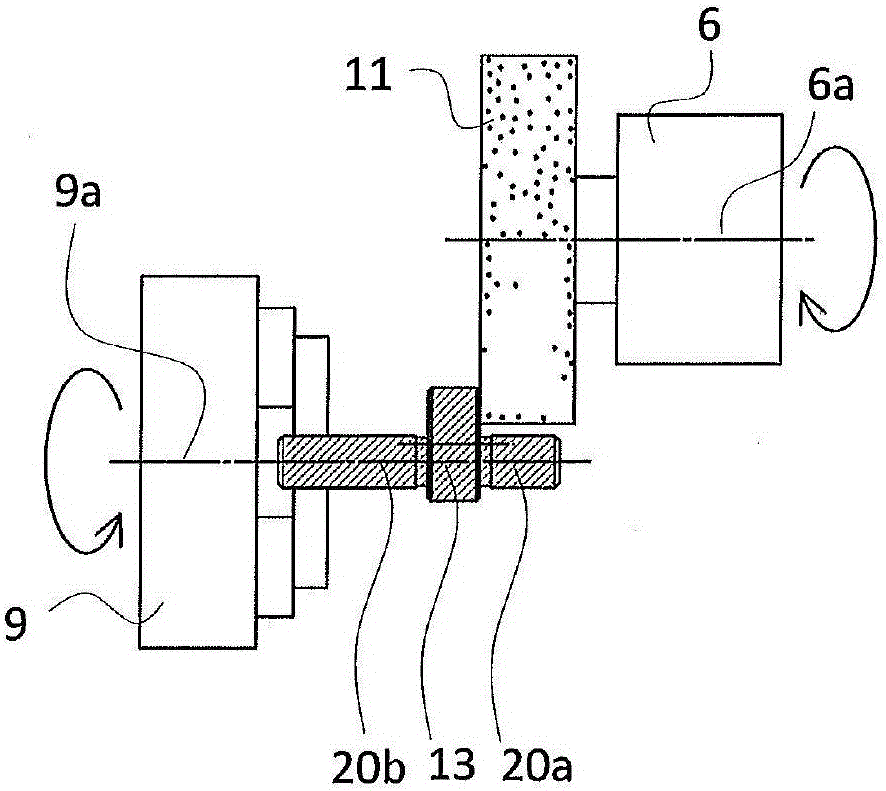

[0048] based on figure 1 The structure of the cylindrical grinder 100 which concerns on this embodiment is demonstrated. The lathe bed 1 that constitutes the base of the cylindrical grinding machine 100 is equipped with: the X-axis table 2 and the grinding wheel conveying device 4 that guide the conveying (X axis) of the grinding wheel; and the conveying (Z axis) to the main shaft 8 axis) to guide the Z-axis table 3 and the Z-axis conveying device 5. The X-axis table 2 and the Z-axis table 3 that move on the guide surface on the bed 1 are equipped with a combination device of a servo motor and a ball screw or a linear motor device as a conveyance drive mechanism. A grinding wheel spindle 6 and a grinding whee...

Embodiment approach 2

[0089] Figure 14 It is a figure which shows the processing process of the cylindrical grinding machine 100 which concerns on this embodiment.

[0090] Such as Figure 14 As shown, a crankshaft is processed by using an external cylindrical grinder 100, and the crankshaft includes: a cylindrical major axis portion 20a and a minor axis portion 20b concentric with each other; and a cylindrical eccentric portion 13 formed on the major axis portion Between 20a and the short-axis portion 20b, there is a center offset from the centers of the long-axis portion 20a and the short-axis portion 20b. In addition, in Figure 14 The minor axis portion 20b is not shown in FIG. The cylindrical grinder 100 performs grinding of the outer diameter of the eccentric portion 13 , continuous micro-curved surface processing of the thrust surface 12 , and cylindrical transverse grinding of the major axis portion simultaneously. The "simultaneous processing" mentioned here means "using the same chuc...

Embodiment approach 3

[0103] Figure 19 It is a vertical cross-sectional view showing the configuration of a rotary compressor 50 for refrigeration and air-conditioning using the crankshaft 20 according to the present embodiment.

[0104] Figure 20 It is a sectional view showing the mechanism of the compression chamber of the rotary compressor 50 according to this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com