Three-axis robot and arm and using method thereof

A robot arm and robot technology, applied in the field of robotics, can solve the problems of large volume, high manufacturing cost, complex structure, etc., and achieve the effect of small size, low manufacturing cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

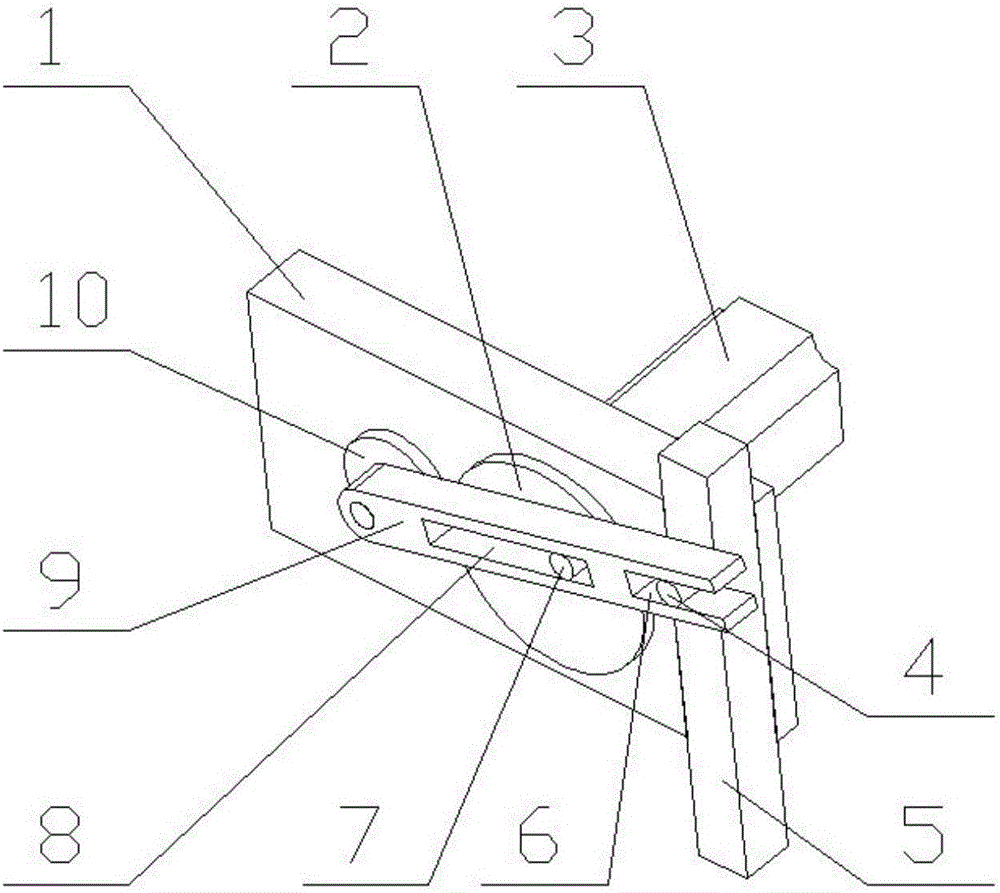

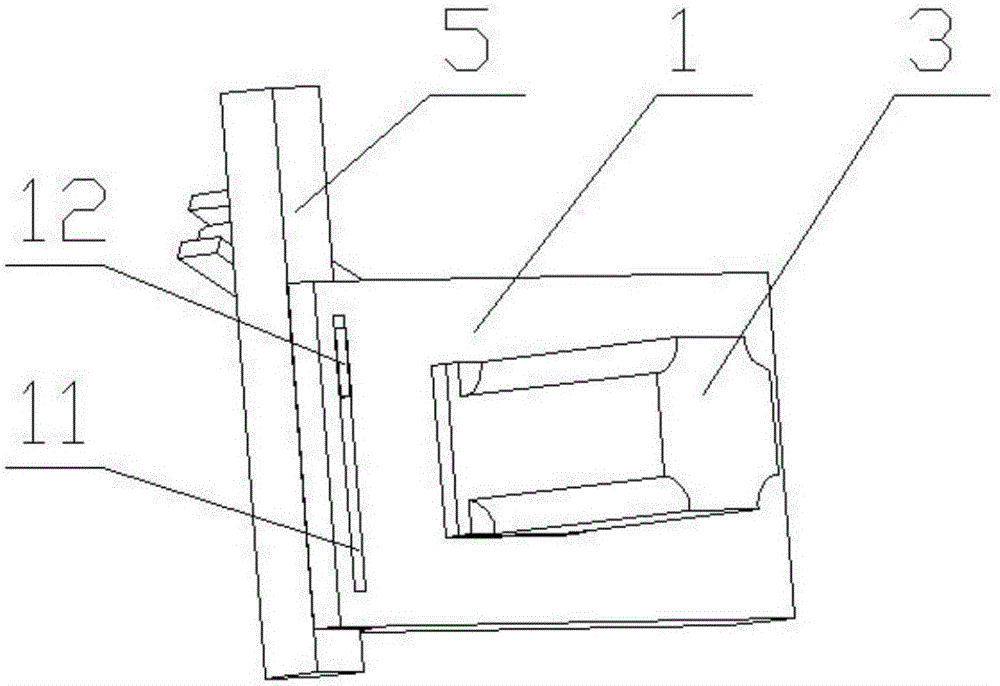

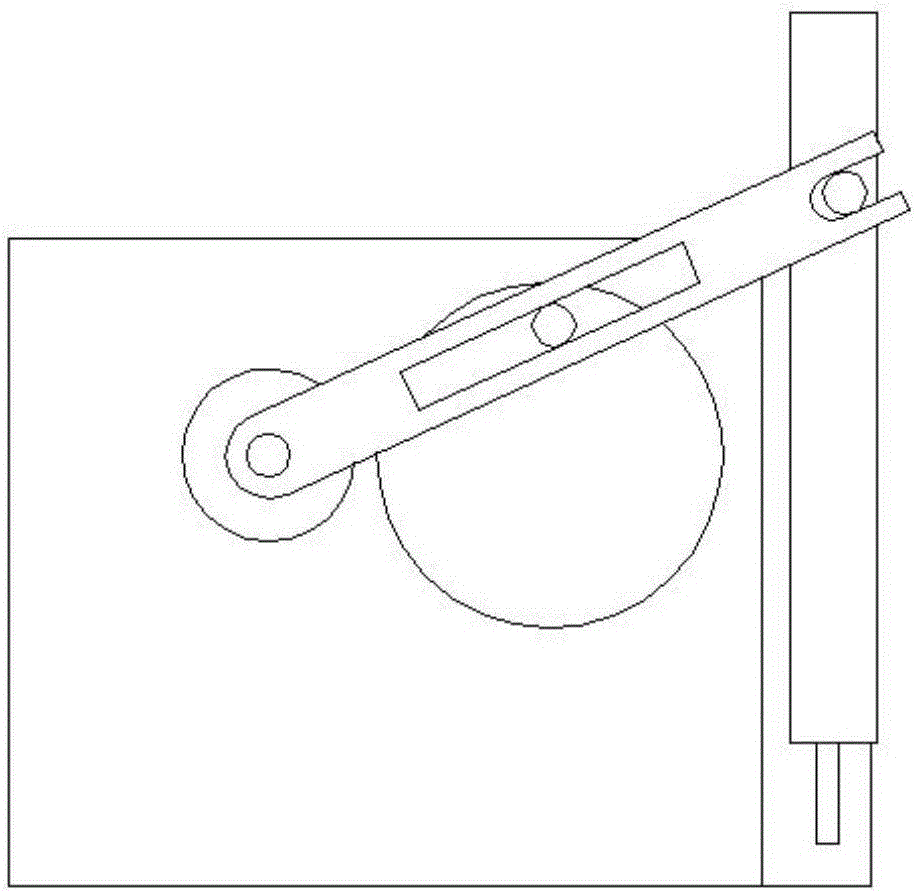

[0048] like figure 1 As shown, a three-axis robot arm includes a main frame 1, a servo motor 3 and a lifting arm 5 arranged at the end of the main frame 1, such as figure 2 As shown, the end of the main frame 1 is provided with a third chute 11, the length of the third chute 11 is L=100mm, the middle part is provided with a runner 2 and a lifting arm 9; the lifting arm 5 is provided with a second protrusion 12; the second protrusion 12 is set in the third chute 11; one end of the lifting arm 9 and the center of the runner 2 are connected to the main frame 1 through the pin shaft; the lifting arm 9 and the runner 2 can be wound around the pin shaft Rotate relative to the main frame 1; the axis of the pin shaft at one end of the lifting arm 9, the center line of the runner 2 and the surface of the main frame 1 intersect to form two points The connection line is perpendicular to the straight line where the chute is located; the runner 2 is provided with The eccentric column 7; th...

Embodiment 2

[0063] A three-axis robot arm, the same as Embodiment 1, the difference is that a rotating base plate 10 is provided at the joint between the pulling arm 9 and the runner 2; the rotating base plate 10 is fixedly connected with the running wheel 2; the pulling arm 9 One end of the pin shaft connected with the running wheel 2 is fixedly connected with the running wheel 2, and the other end passes through the lifting arm 9 so that the lifting arm 9 can rotate around the pin shaft.

[0064] This embodiment can have the same beneficial effect as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com