Bucket type elevating ship loader

A bucket elevator and ship loader technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of poor sealing performance, long occupied track length, complicated installation, etc., and achieve good sealing performance, easy sealing, and shortened The effect of the itinerary

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

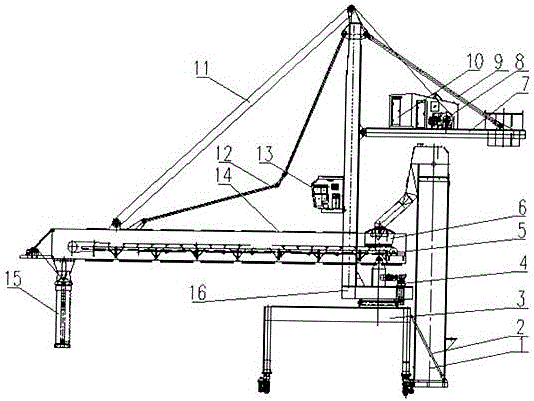

[0012] This technical solution is suitable for the working conditions where the wharf track is short, the material particles are small, and dust is likely to be generated at the material transfer point during transportation. It can meet the bucket elevator type ship loader installed in multiple places in the wharf according to the unloading situation. Specific examples figure 1 As shown, the hoist is connected with the upstream conveying belt conveyor system, and the material is transferred from the upstream to the hoist. The hoist is fixed on the platform support by high-strength bolts and connected with the door frame 3 by a pull rod 2. There are at least four pull rods to ensure the stability of the hoist. When working, the hoist can move with the cart traveling mechanism installed on the lower part of the mast. The other end of the material barrel is inserted into the funnel 14, and a slewing support 4 is installed on the upper part of the door frame. The slewing support i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com