Industrial wastewater treatment device

A treatment device and technology for industrial wastewater, applied in the direction of aerobic process treatment, heating water/sewage treatment, neutralized water/sewage treatment, etc. The mud effect is not ideal and other problems, to achieve the effect of small filter layer resistance, ideal reaction conditions, suitable for microbial growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

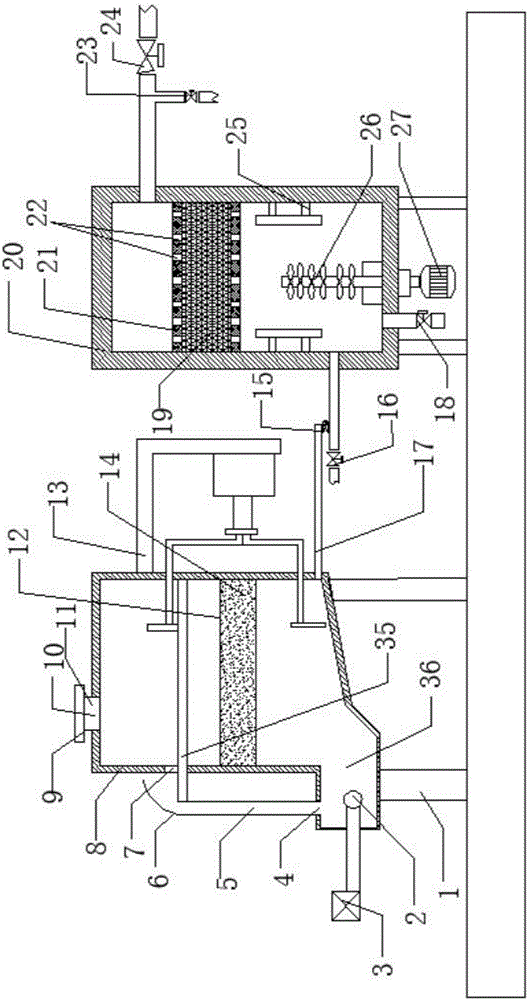

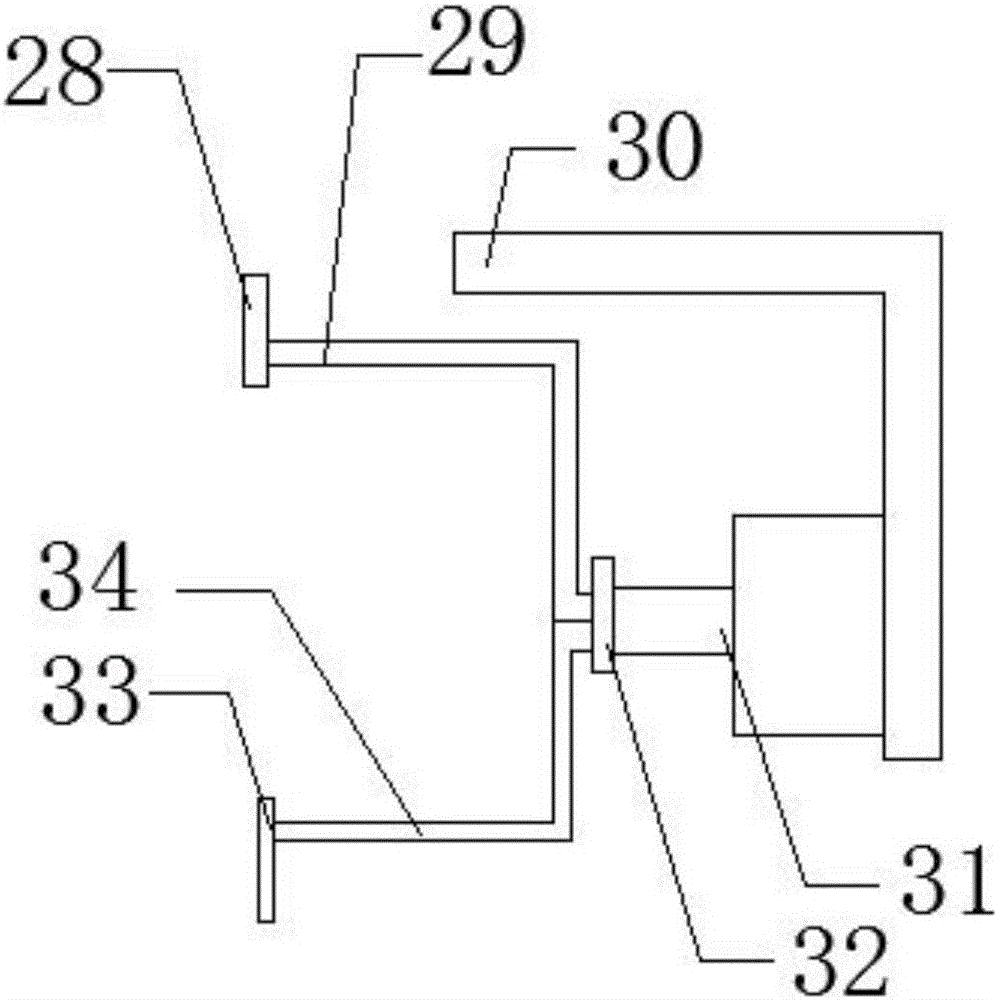

[0026] figure 1 and figure 2 The specific embodiment of the present invention: a kind of industrial wastewater treatment device, comprising support 1, decontamination device and aeration tank, described decontamination device and aeration tank are all installed on the support 1, decontamination device and aeration tank The pools are connected by pipelines 17, and the decontamination device includes a water treatment tank 8, a mud scraping assembly 13, a filter screen 35 and a neutralizing agent filter layer, and one end of the water treatment tank 8 is provided with a collection tank 36 for filtering The screen plate 35 and the neutralizer filter layer are fixed inside the water treatment tank 8 from top to bottom in sequence. A mud scraper 28, a second connecting rod 33, and a second mud scraper 34 are formed. The side walls of the water treatment tank body 8 are respectively provided with a first through hole, a second Two through holes, the push rod motor 31 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com