A kind of water-soluble polyester resin with hydroxy acid end cap and preparation method thereof

A technology of water-soluble polyester and hydroxy acid, applied in the field of polyester resin, can solve the problems of unstable cost and poor storage stability of polyester aqueous dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

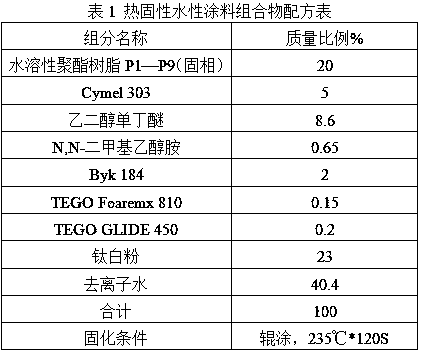

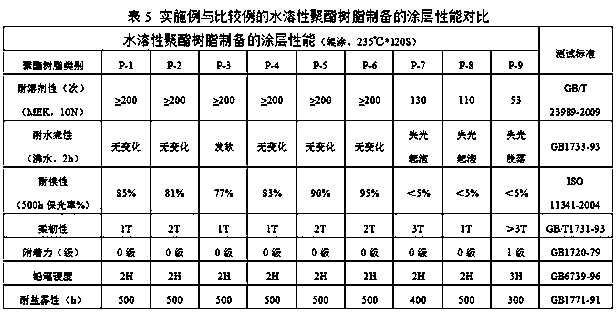

Examples

Embodiment 1

[0052] Add 2340 parts of dimethylpropanediol, 192 parts of 2-ethyl-2-butylpropanediol, 210 parts of trimethylolpropane, 89 parts of ethylene glycol to a reaction kettle equipped with a stirrer, reflux condenser and thermometer Alcohol and 130 parts of 1,4-cyclohexanedicarboxylic acid, 2510 parts of isophthalic acid, 1623 parts of adipic acid, and 9 parts of dibutyltin oxide were heated from room temperature to 140 ℃, raise the temperature of the reaction system from 140 ℃ to 240 ℃ at a rate of 8 ℃ per hour for esterification reaction, keep at 240 ℃ for 1.5 hours, the total esterification reaction time is 8 hours, and the acid value is less than 50mgKOH / g , adjust the vacuum degree of the reactor to be -0.1~-0.12MPa to carry out the polycondensation reaction. After 1 hour, the acid value of the reactant is 40mgKOH / g, the hydroxyl value is 30~50mgKOH / g and the number average molecular weight is 3000~5000, and the polyester is obtained. carboxyl-terminated prepolymer. Cool the r...

Embodiment 2

[0054]Add 1300 parts of dimethylpropanediol, 1527 parts of 2-ethyl-2-butylpropanediol, 129 parts of trimethylolpropane, 310 parts of 1,6-hexanediol and 426 parts of 1 , 4-cyclohexanedicarboxylic acid, 2573 parts of isophthalic acid, 1000 parts of terephthalic acid, 453 parts of hexahydrophthalic anhydride, and 12 parts of tetra-n-butyl titanate, with nitrogen gas constantly stirring Under normal circumstances, heat from room temperature to 140°C, raise the temperature of the reaction system from 140°C to 240°C at a rate of 8°C per hour for esterification reaction, reach 240°C for 1.5 hours, and the total esterification reaction time is 8.5 hours. When the acid value is less than 50mgKOH / g, adjust the vacuum degree of the reactor to -0.11~-0.13MPa for polycondensation reaction. After 1 hour, the acid value of the reactant is 35mgKOH / g, the hydroxyl value is 30~50mgKOH / g and the number average molecular weight is 3000~5000 to obtain polyester carboxyl-terminated prepolymer. Coo...

Embodiment 3

[0056] Add 1990 parts of 2-methyl-1,3-propanediol, 100 parts of 2-ethyl-2-butylpropanediol, 78 parts of ethylene glycol, 273 parts of 1,6-hexanediol to the above reaction kettle With 1535 parts of dodecanedioic acid, 1000 parts of isophthalic acid, 1873 parts of 1,6-adipic acid, 178 parts of trimellitic anhydride, and 15 parts of dibutyltin oxide, from room temperature under constant stirring with nitrogen Heating to 140°C, raising the temperature of the reaction system from 140°C to 240°C at a rate of 8°C per hour for esterification reaction, reaching 240°C for 2 hours, the total esterification reaction time is 10 hours, and the acid value is less than 50mgKOH / g, vacuuming and adjusting the vacuum degree of the reactor to -0.09~-0.1MPa for polycondensation reaction, 1.5 hours until the acid value of the reactant is 30mgKOH / g, the hydroxyl value is 30~50mgKOH / g and the number average molecular weight is 3000~5000, A polyester carboxyl-terminated prepolymer is obtained. Cool d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com