High-rigidity, high-melt-strength and low-temperature-impact-resistant thermo-plastic ABS resin composition used for blow molding

A high melt strength, ABS resin technology, applied in the field of thermoplastic ABS resin composition, can solve the problems of unbalanced melt strength, rigidity and low temperature toughness, high melt strength, etc., and achieve improved melt flow rate and shear viscosity , high melt strength and excellent low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

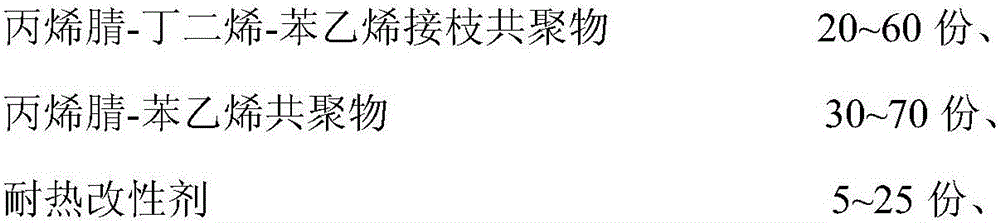

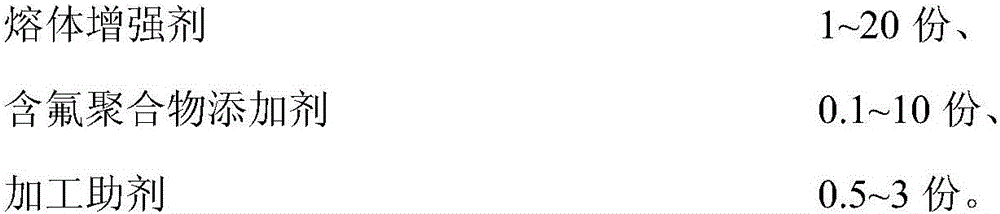

Method used

Image

Examples

Embodiment 1

[0045] 40 parts of acrylonitrile-butadiene-styrene graft copolymer, 50 parts of acrylonitrile-styrene copolymer, 10 parts of heat-resistant modifier (HR-2), 5 parts of melt enhancer (MR-1) , 3 parts of fluoropolymer additive (FA-1), 0.6 part of processing aid. The raw materials were weighed according to the above parts, and the ABS resin composition for blow molding was prepared by the following method:

[0046] (1) Fully mix the prepared raw materials in a high-speed mixer for 30 minutes;

[0047] (2) The premixed material prepared in step 1 is sent into the twin-screw extruder through the metering device, under the conveying, shearing and mixing of the screw, the material is melted and compounded, and then extruded, drawn, cooled, In the pelletizing step, a high-rigidity, high-toughness, and high-melt strength thermoplastic ABS resin composition for blow molding is obtained. The screw aspect ratio of the twin-screw extruder is 36-44, and the vacuum degree is controlled at ...

Embodiment 2-7、 comparative example 1-3

[0049] In order to reflect the inventiveness of the present invention by comparison, the ratios of Examples 2-7 are based on Example 1, respectively comparing different types of heat-resistant modifiers (α-methylstyrene) and fluoropolymer additives. The effect of addition amount, different types of melt reinforcing agents, compounding of different types of melt reinforcing agents, and compounding of different types of fluoropolymer additives on the performance of the material, the specific preparation method is the same as that of Example 1, and the ratio of raw materials is shown in Table 1. In addition, the processing aids in Examples 2 to 7 can be any value in the range of 0.5 to 3.0, and the material components can be one or more of antioxidants, lubricants, and mold release agents. The comparability of 1, the weight fraction selected here is 0.6.

[0050] The raw material formula of table 1 embodiment 1-7 and comparative example 1-3

[0051]

[0052]

[0053] Note:...

Embodiment 8

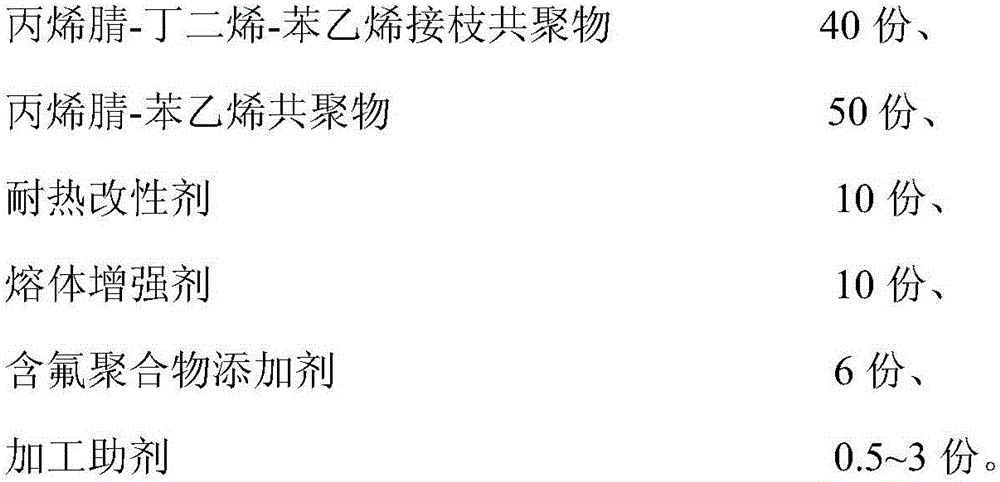

[0068] Embodiment 8 Preparation of thermoplastic ABS resin with high rigidity, high melt strength and low temperature impact resistance

[0069] 40 parts of acrylonitrile-butadiene-styrene graft copolymer, 50 parts of acrylonitrile-styrene copolymer, 10 parts of heat-resistant modifier (HR-1), 10 parts of melt enhancer (MR-1) , 6 parts of fluoropolymer additive (FA-3), 0.6 part of processing aid. The raw materials were weighed according to the above parts, and the ABS resin composition for blow molding was prepared by the following method:

[0070] (1) Fully mix the prepared raw materials in a high-speed mixer for 30 minutes;

[0071] (2) The premixed material prepared in step 1 is sent into the twin-screw extruder through the metering device, under the conveying, shearing and mixing of the screw, the material is melted and compounded, and then extruded, drawn, cooled, In the pelletizing step, a high-rigidity, high-toughness, and high-melt strength thermoplastic ABS resin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com