In-mold gel coat for wind power blades

A technology for wind turbine blades and gel coats, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of low weather resistance and long curing time, and achieve obvious weather resistance, short mold time, and low irritation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] This example provides a highly weather-resistant and fast-curing polyurea in-mold gel coat for wind power blades. The in-mold gel coat includes a main agent and a curing agent.

[0068] The main ingredient comprises the following components by weight:

[0069] Resin A1 100 parts;

[0070] Pigment and filler 0-100 parts;

[0071] Auxiliary 0-10 parts;

[0072] The resin A1 is a polymer formed by Michael addition reaction of diethyl maleate and hexamethylene diamine.

[0073] The pigment and filler are specifically weather-resistant rutile titanium dioxide.

[0074] Curing agent wherein is Desmodur N100, Desmodur N3300, DesmodurN3600 of Covestro Company, Tolonate HDT of Vencorex Company or similar products of other companies or isocyanate (NCO) weight content is a kind of in the aliphatic prepolymer of 1~20%

[0075] And the dosage of the curing agent is 50-100% of the weight of the resin A1 in the main agent.

[0076] Based on this, a weather-resistant fast-curing p...

Embodiment 2

[0078] This example provides a highly weather-resistant and fast-curing polyurea in-mold gel coat for wind power blades. The in-mold gel coat includes a main agent and a curing agent.

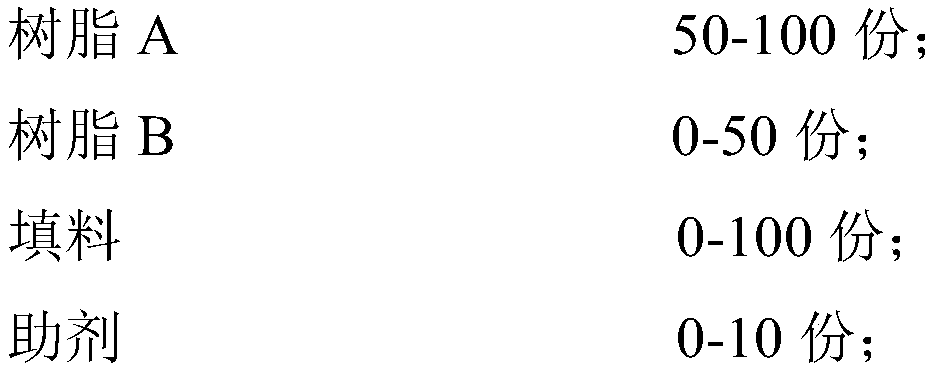

[0079] The main ingredient comprises the following components by weight:

[0080]

[0081] The resin A1 is a polymer formed by Michael addition reaction of diethyl maleate and hexamethylene diamine.

[0082] Resin B1 is a polymer formed by Michael addition reaction of diethyl maleate and amino-terminated polyether with a molecular weight of 230.

[0083] The pigment and filler are specifically weather-resistant rutile titanium dioxide.

[0084] Curing agent wherein is Desmodur N100, Desmodur N3300, DesmodurN3600 of Covestro Company, Tolonate HDT of Vencorex Company or similar products of other companies or isocyanate (NCO) weight content is a kind of in the aliphatic prepolymer of 1~20%

[0085] And the dosage of the curing agent is 50-100% of the weight of the resin in the main agent.

...

Embodiment 3

[0088] This example provides a highly weather-resistant and fast-curing polyurea in-mold gel coat for wind power blades. The in-mold gel coat includes a main agent and a curing agent.

[0089] The main ingredient comprises the following components by weight:

[0090]

[0091] Resin A2 wherein is the polymer that diethyl maleate and 4.4' diaminodicyclohexylmethane form by Michael addition reaction.

[0092] Resin B2 is a polymer formed by Michael addition reaction of dimethyl maleate and amino-terminated polyether with a molecular weight of 230.

[0093] The pigment and filler are specifically weather-resistant rutile titanium dioxide.

[0094] Curing agent wherein is Desmodur N100, Desmodur N3300, DesmodurN3600 of Covestro Company, Tolonate HDT of Vencorex Company or similar products of other companies or isocyanate (NCO) weight content is a kind of in the aliphatic prepolymer of 1~20%

[0095] And the dosage of the curing agent is 50-100% of the weight of the resin in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com