Rotary multifunctional enzymolysis fermentation machine and fermentation process thereof

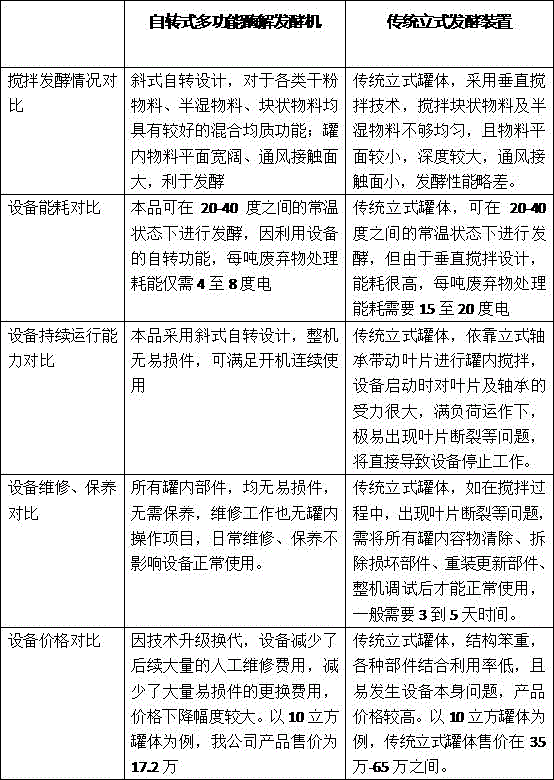

A multi-functional enzyme and fermentation machine technology, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, enzymology/microbiology device, etc., can solve the problem of low combined utilization of components and paid maintenance , small ventilation contact surface, etc., to achieve the effect of reducing manual maintenance costs, large price reduction, and large ventilation contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

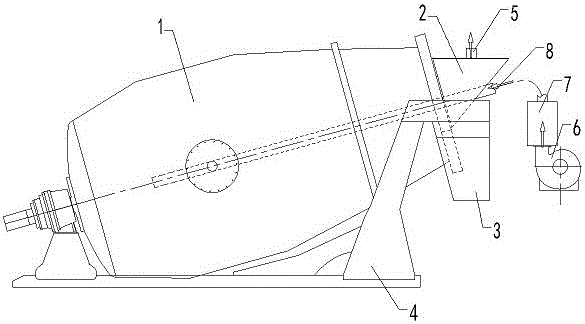

[0028] Examples such as figure 1 As shown, the self-rotating multi-functional enzymolysis fermentation machine includes a tank body 1, which is arranged in an oblique rotation, and adopts a stirring tank structure provided with a sealed air supply device, and the top of the tank body 1 is sealed and connected with the air supply device , and the temperature, ventilation, humidity and drying program are automatically set through the air supply device to assist fermentation.

[0029] The inclination angle between the central axis of the tank body 1 and the horizontal ground is 13-16 degrees. Due to the use of the rotation function of the equipment, the energy consumption per ton of waste treatment only needs 4-8 degrees of electricity, and the tank body 1 can be used at 20- Fermentation at room temperature between 40 degrees.

[0030] The air supply device includes an air supply pipe 8 arranged coaxially with the tank body 1 and installed inside the tank body 1 for ventilation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com