Microbial agent for humus organic matter degradation and preparation method thereof

A microbial agent and organic matter technology, applied in the field of microbial agent and its preparation, can solve the problem that microorganisms cannot adapt to complex climates and effectively deal with various types of organic waste, lignin and cellulose substances that are difficult to degrade, and project costs To achieve the effects of easy and rapid mass production, accelerated degradation speed, and enhanced weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, the present invention will be further described in conjunction with the examples. It should be understood that the examples are only for illustration and not intended to limit the protection scope of the present invention.

[0027] The microorganisms used in the embodiment are as follows:

[0028] 1). Actinobacteria, generally thermophilic actinomycetes

[0029] 2). White rot fungus Phanerochaetc chrysosporium

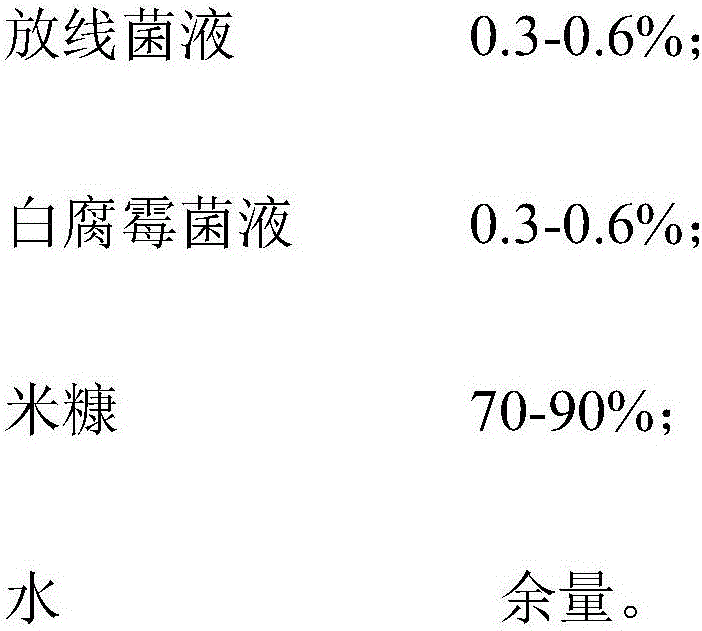

[0030] Raw material consumption according to weight percentage:

[0031] 1) Actinomycetes solution 0.5%

[0032] 2) White rot mold solution 1.0%

[0033] 3)Rice bran 85%

[0034] 4) Water balance

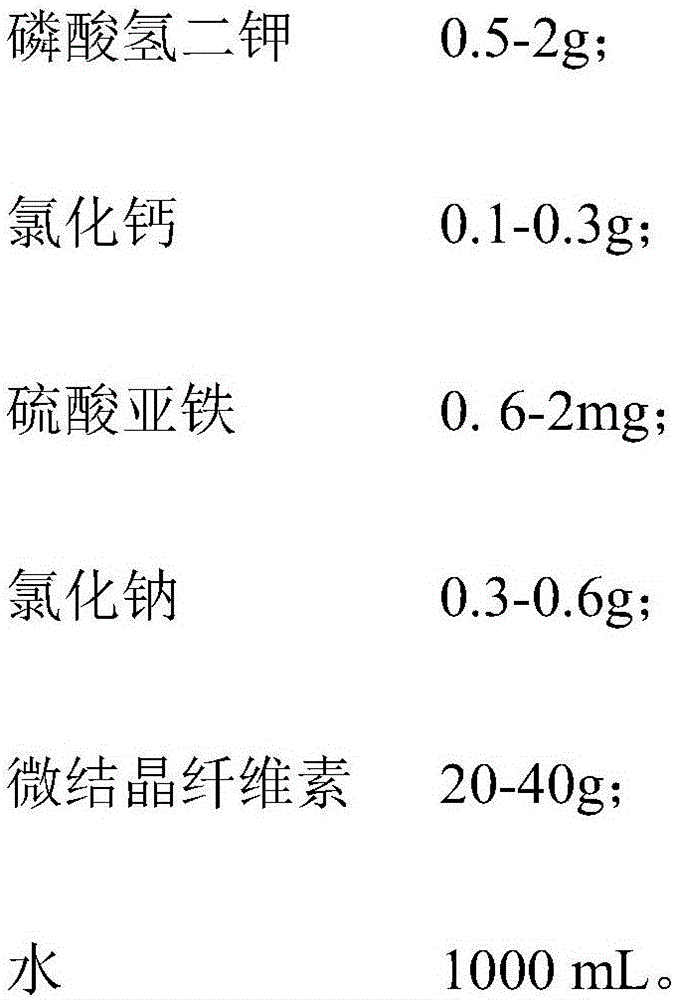

[0035] The content of each component of actinomycetes per liter of medium solution:

[0036]

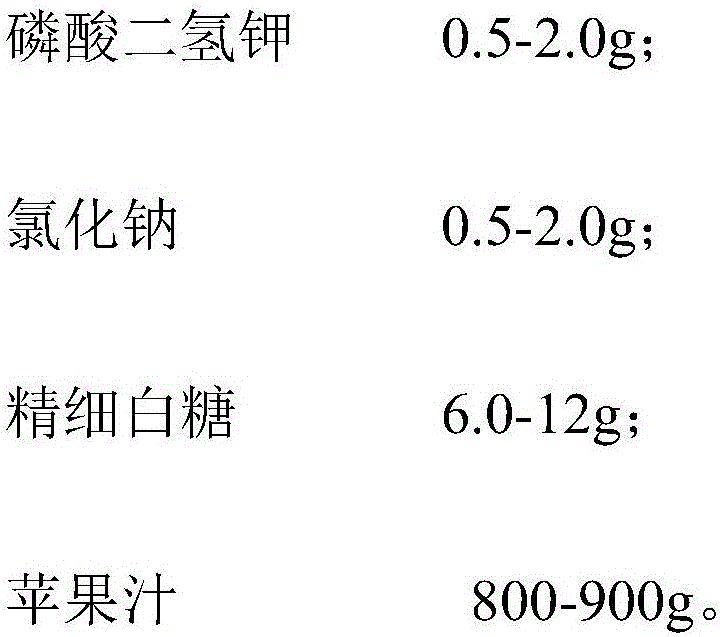

[0037] The content of each component of white rot mold per liter of medium solution:

[0038]

[0039] The preparation method of the microbial composite bacterial agent for the degradation of humic organic matter, the specific steps are as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com