Aluminum alloy material for aerospace large thick castings and preparation method thereof

An aluminum alloy material and aluminum alloy technology, which is applied in the field of aluminum alloy manufacturing, can solve the problems of inability to meet the mass production of aerospace castings and high production costs, and achieve the effects of low cost, reducing harmful effects and overcoming high gas content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

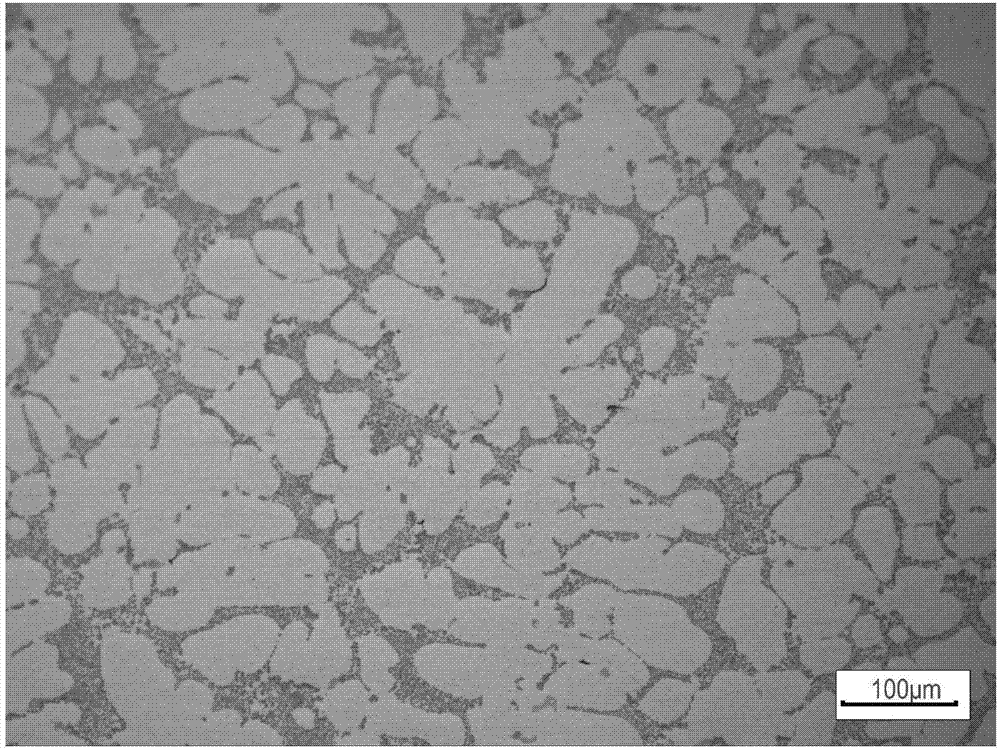

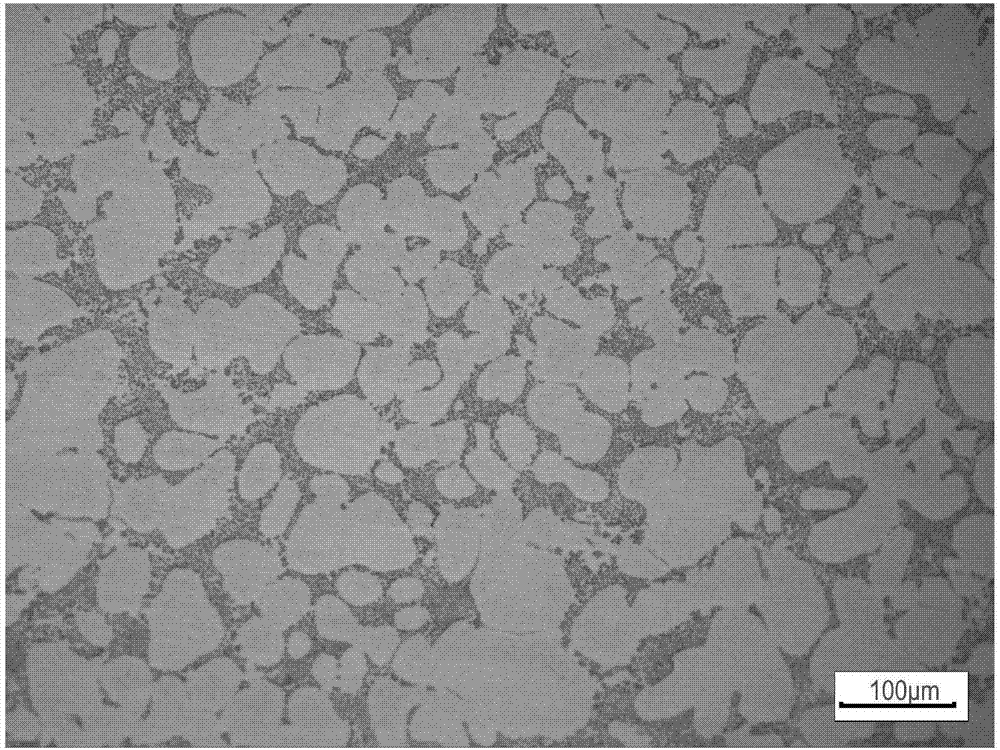

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

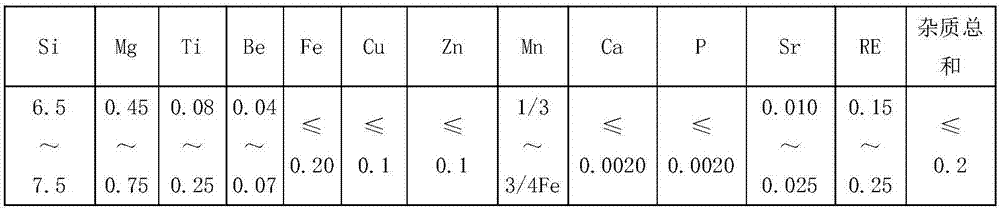

[0034] An aluminum alloy material for aerospace large-scale thick castings, its components and mass percentages are:

[0035]

[0036] (1) Weigh common aluminum (Al≥99.70%), metal silicon (441), metal magnesium (Mg≥99.95%), titanium intermediate (AlTi10), beryllium intermediate (AlBe3), manganese intermediate (AlMn10) according to the above proportions , titanium boron rod (AlTi5B1), strontium intermediate (AlSr10), mixed rare earth RE; among them, metal silicon is crushed 1~5cm 3 of small pieces.

[0037] (2) Weigh ST sodium-free refining agent according to 0.1-0.2% of the total feeding;

[0038] (3) Use a forklift to put the aluminum ingots and silicon metal for remelting in step (1) into a 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com