Construction method for mounting layer-divided sinking apparatus in deep compressible soil layer

A layered settlement and construction method technology, applied in the field of foundation soil survey, infrastructure engineering, construction, etc., can solve problems such as distortion of observation results, achieve the effects of avoiding settlement, ensuring durability, and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The present embodiment is for further improving the method of the present invention, before carrying out described step (1), the specific content of preparatory work of adding earlier stage, preparatory work of early stage comprises collecting and installing the geological prospecting report of layered settlement instrument soil layer, and using The relevant technical parameters of the layered settlement instrument, and through no less than three groups of indoor tests, determine the cubic uniaxial compressive strength of the cement slurry standard test block.

[0057] Among them, it is necessary to collect geological survey reports and instrument manuals issued by instrument manufacturers, and to master the instrument size, total weight, soil side friction resistance qu, end resistance qp, soil compression modulus Esi measured by standard penetration tests, etc. Design parameters, no less than three sets of indoor tests, to determine the cubic uniaxial compressive stren...

Embodiment 2

[0064] In this embodiment, on the basis of the above embodiments, the process of grouting the borehole is further described in detail, including the following steps:

[0065] (2.1) According to the actual situation, design reasonable grouting construction parameters, and use the designed grouting construction parameters as the reference value for actual construction; among them, the specific grouting construction parameters are, use ordinary portland cement grout as grouting For grouting materials, the grouting pressure is not greater than 0.5MPa, the grouting water-cement ratio is 1:0.55, and the grouting speed is not greater than 50L / Min;

[0066] (2.2) Make and install the grouting device;

[0067] (2.3) Grouting into the borehole, when the corresponding design grouting parameters have been reached or approached, stop grouting;

[0068] (2.4) After the grouting is completed, recover the grouting device within 20 minutes. After 1 hour, lower the hammer measuring rope to mea...

Embodiment 3

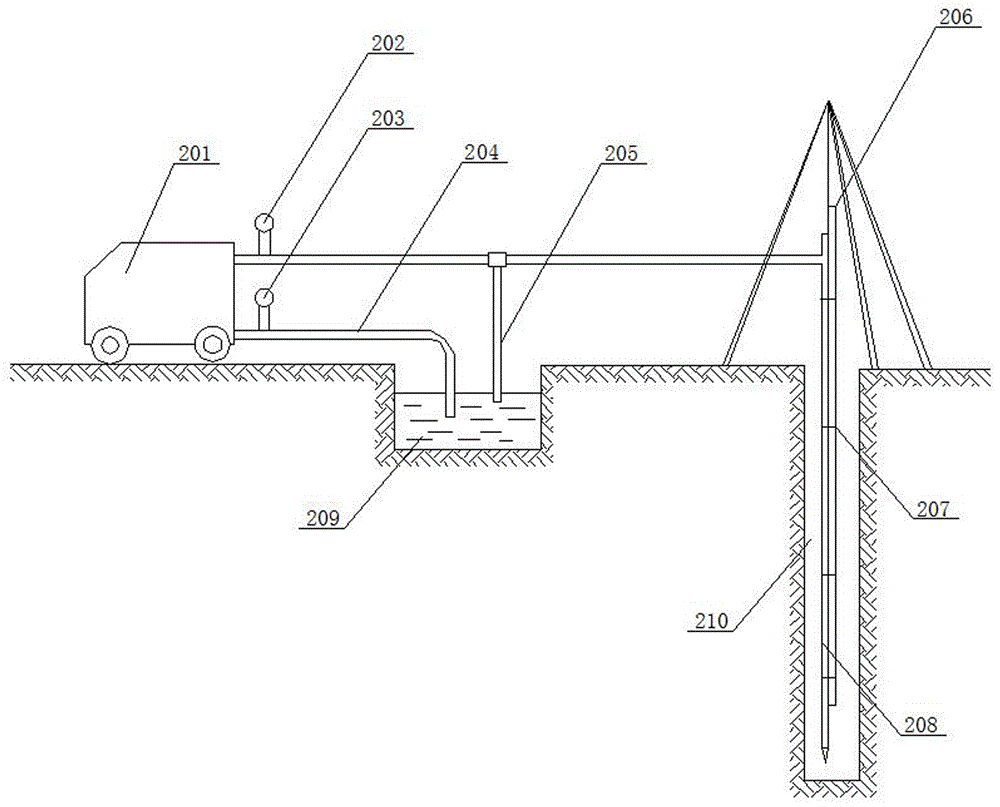

[0081] On the basis of the above-mentioned embodiments, this embodiment further defines the structure of the grouting device, such as figure 2 As shown, the grouting device includes a pressure mud pump 201 and a grouting pipe 208, and the pressure mud pump 201 is provided with a grout inlet pipe 204 for extracting slurry from a slurry pool 209, and a grout outlet pipe communicated with the grout pipe 208, The grouting pipe 208 is placed in the borehole 210; the grouting pipe 204 is also provided with a flow meter 203, the grouting pipe is also provided with a pressure gauge 202, and the middle part of the grouting pipe is also provided with an inlet The slurry discharge pipe 205 of the slurry tank 209.

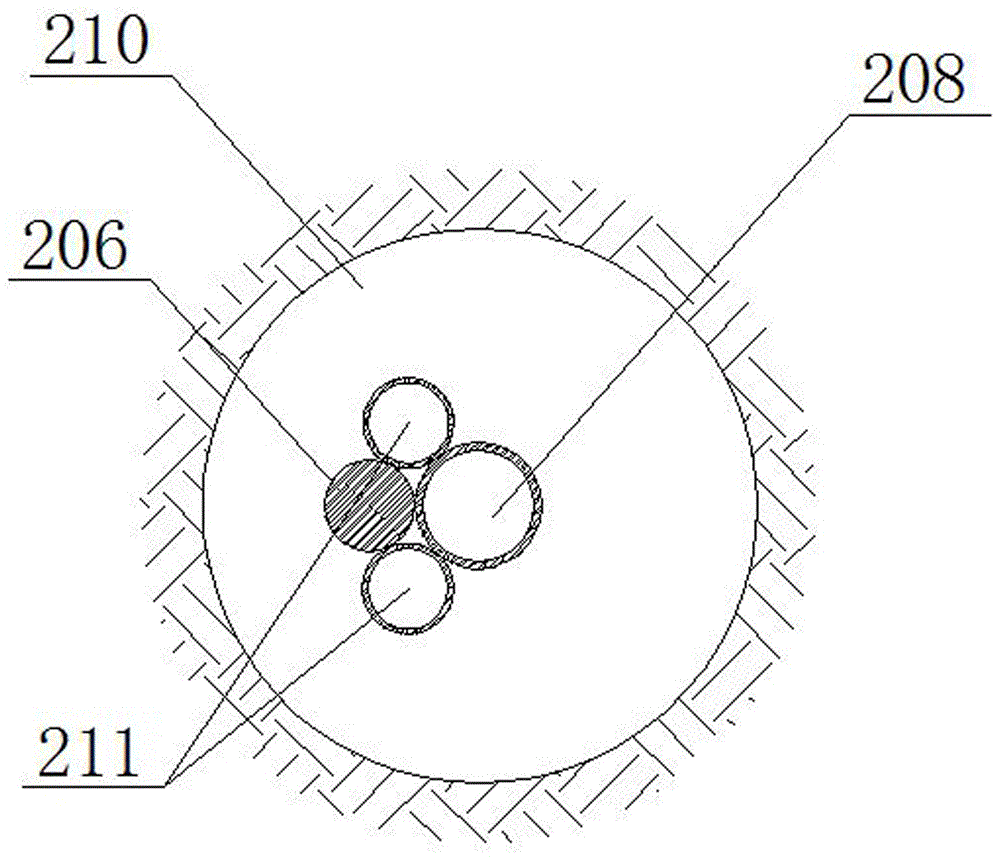

[0082] The grouting device also includes a tripod set up at the drilling hole, such as figure 2 , image 3 As shown, the tripod is hoisted with guiding steel bars 206, the guiding steel bars 206 are fixed with the grouting pipe 208 by at least two welded pipes 211, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com