Gas turbine motor for rotary combustion chamber

A technology of rotating combustors and gas turbines, which is applied to gas turbine devices, machines/engines, mechanical equipment, etc. It can solve problems such as complex cooling system structures, reduce production costs, reduce compressor power, and reduce manufacturing difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

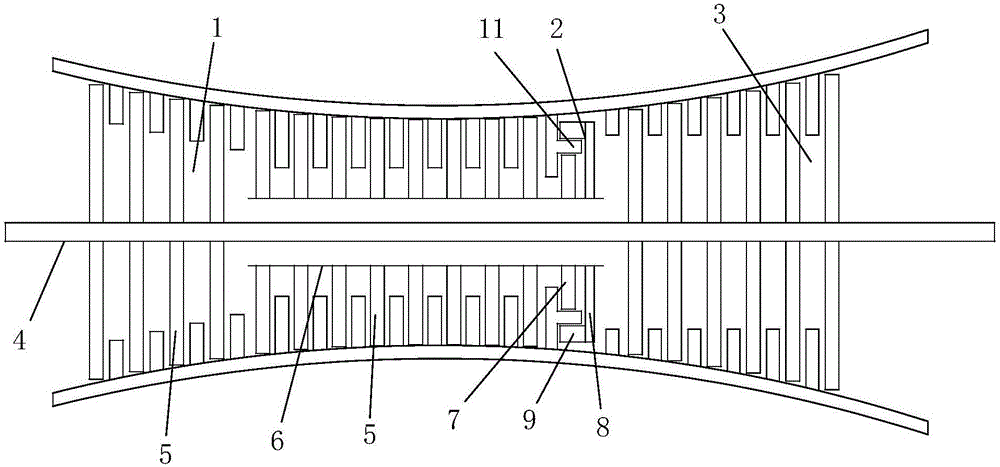

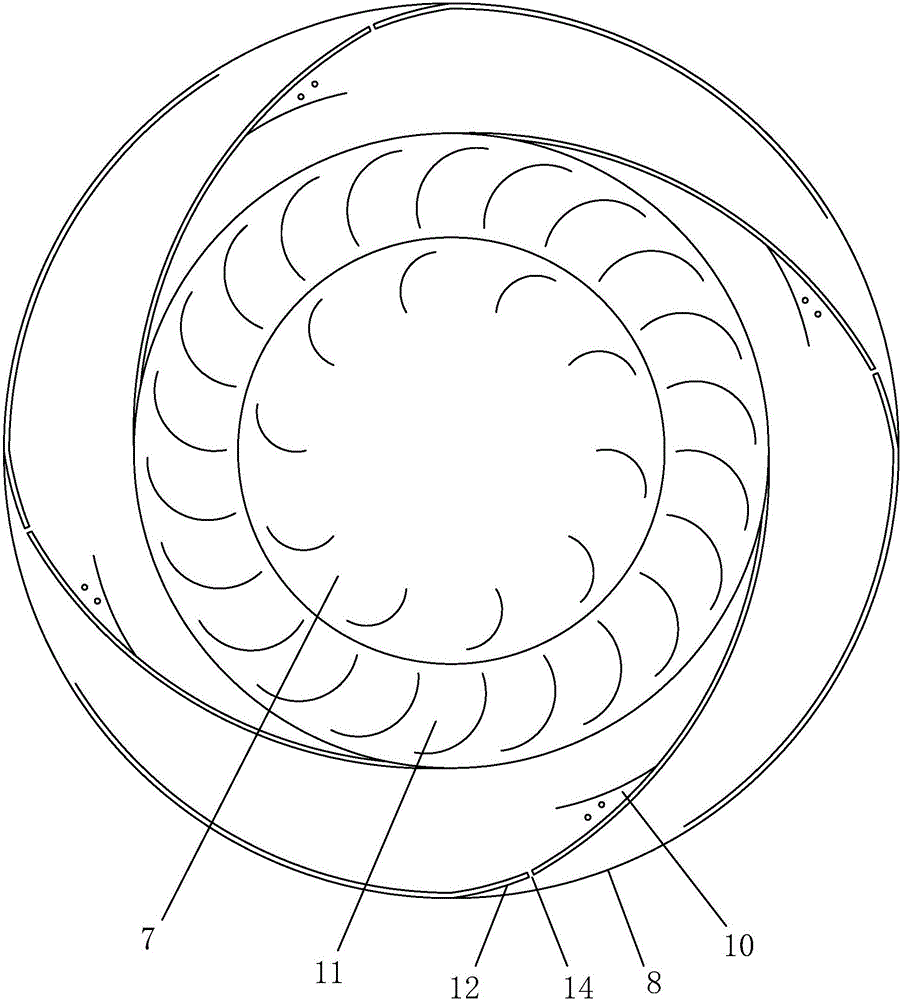

[0030] Such as Figure 1~3 As shown, a gas turbine engine with a rotating combustion chamber includes a compressor 1, a combustion chamber 2, and a turbine 3 arranged adjacently in sequence;

[0031] The compressor includes a low-pressure stage and a high-pressure stage, and the last stage of the compressor is a centrifugal impeller 7; the low-pressure stage includes a low-pressure rotor 4, an impeller 5 arranged on the low-pressure rotor; the high-pressure stage includes a high-pressure rotor 6 set outside the low-pressure rotor, and the The impeller 5 on the high pressure rotor;

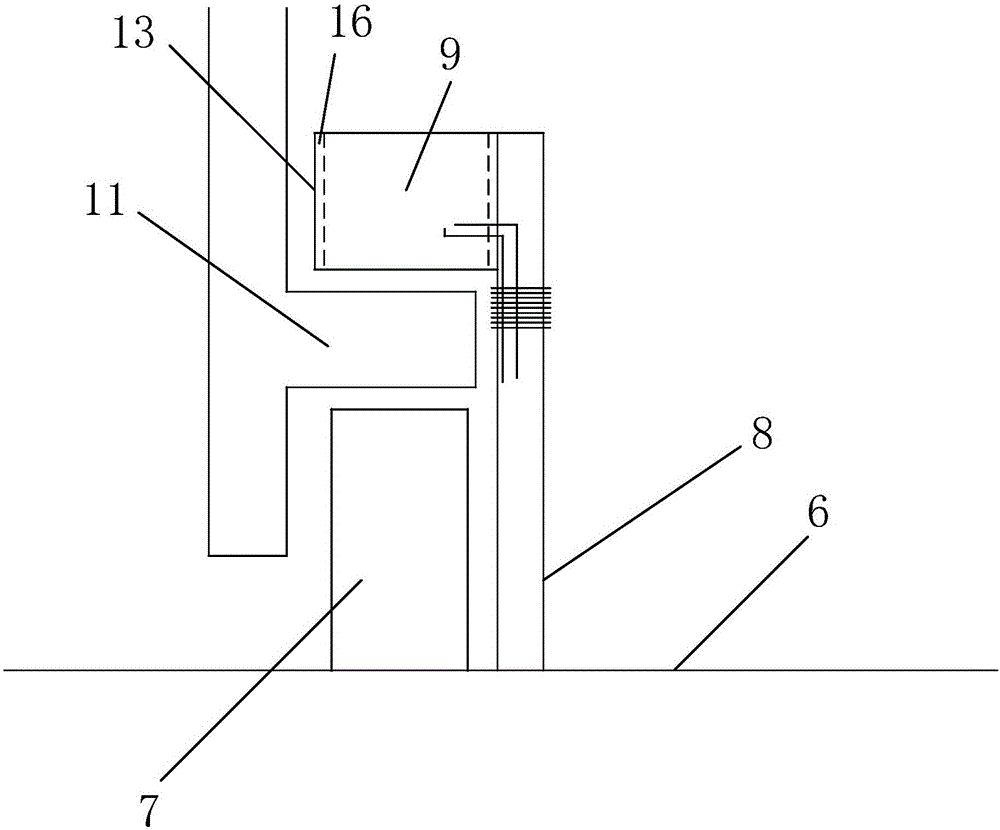

[0032] The combustion chamber includes a turntable 8 arranged on the high-pressure rotor, and more than two annular combustion chambers 9 arranged on one side of the turntable; each annular combustion chamber is provided with a flame chamber 10, and an ignition nozzle is arranged in the flame chamber and fuel nozzles; the annular combustion chamber is located at the edge of the turntable and outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com