Proportional electromagnetic valve used for treating tail gas through solid ammonia

A technology of proportional solenoid valve and solid ammonia, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of low service life of solenoid valve, non-adjustable position of solenoid valve, size requirements of parts assembly, etc., to avoid metal Abrasion, simple structure, effect of improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

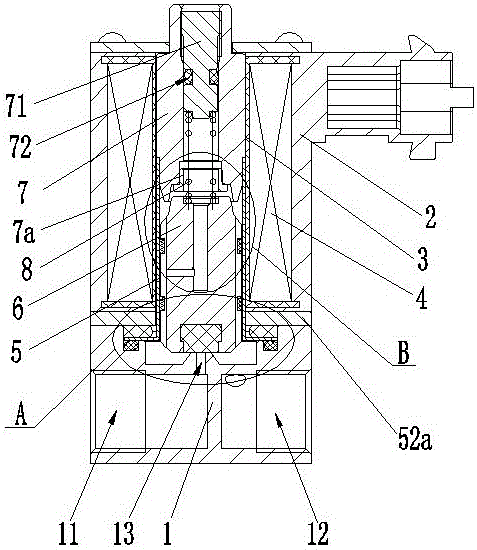

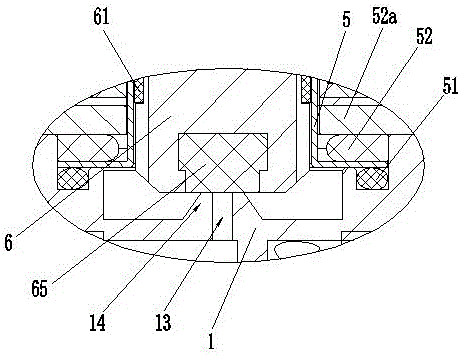

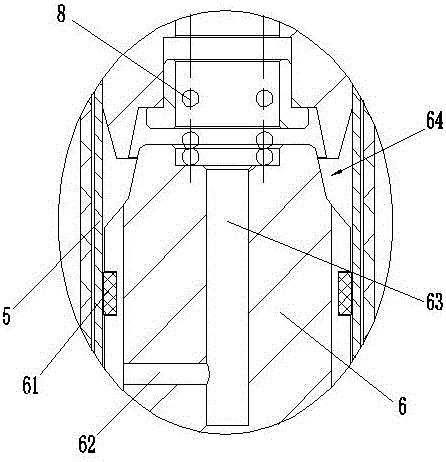

[0022] like Figure 1 to Figure 3 Shown is the structural representation of the present invention,

[0023] The reference signs are: valve body 1, fluid inlet 11, fluid outlet 12, fluid channel 13, round platform 14, shell 2, coil support 3, coil 4, sleeve 5, second sealing ring 51, gasket 52, Intermediate partition 52a, moving iron core 6, wear-resistant ring 61, pressure relief hole 62, pressure relief channel 63, cavity 64, gasket 65, static iron core 7, magnetic isolation ring 7a, manual lever 71, first seal Circle 72, spring 8.

[0024] like Figure 1 to Figure 3 as shown,

[0025] A proportional solenoid valve for treating exhaust gas with solid ammonia, comprising a valve body 1, on which a fluid inlet 11 and a fluid outlet 12 are provided, the fluid inlet 11 and the fluid outlet 12 are connected through a fluid channel 13, the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com