Fast softening, slicing and drying method for traditional Chinese medicine

A drying method and technology of Chinese herbal decoction pieces, which are applied in chemical instruments and methods, biomass drying, and drying solid materials, etc., can solve the problems of reducing the efficacy and active ingredients of Gastrodia elata, loss of active ingredients of Gastrodia elata, and high water content in decoction pieces, so as to achieve good results. Practical value and application prospect, saving traditional Chinese medicine resources, effect of low water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

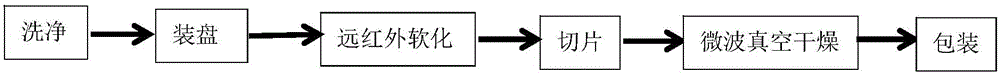

[0047] refer to figure 1 , after cleaning Gastrodia elata, put it into the stainless steel plate of the far-infrared drying oven; turn on the far-infrared drying oven, set the time for 25 minutes, and carry out far-infrared vacuum softening at a temperature of 35 ° C. After slicing, put the gastrodia decoction pieces in the microwave In the stainless steel plate of the vacuum drying oven; turn on the microwave vacuum drying oven, vacuumize, and dry under the conditions of microwave setting 2450MHz, time 30min, temperature 35°C, vacuum degree -0.02MPa. There is a gelatinous layer on the surface of Gastrodia elata decoction pieces.

[0048] The alcohol-soluble extract and gastrodin of the above-mentioned Tianma decoction pieces were detected, and the results showed that the alcohol-soluble extract of the Gastrodia elata decoction pieces was 55.1.6%, the gastrodin was 3.22%, and the water content was 7.3%. After being placed in the open air indoors for 3 days, the measured mois...

Embodiment 2

[0050] refer to figure 1 , after cleaning Gastrodia elata, put it into the stainless steel plate of the far-infrared drying oven; turn on the far-infrared drying oven, set the time for 20 minutes, and perform far-infrared vacuum softening at a temperature of 45°C, slice it, and put the Gastrodia elata decoction pieces in the microwave In the stainless steel plate of the vacuum drying oven; turn on the microwave vacuum drying oven, vacuumize, and dry under the conditions of microwave setting 2450MHz, time 20min, temperature 45°C, vacuum degree -0.04MPa. There is a gelatinous layer on the surface of Gastrodia elata decoction pieces.

[0051] The alcohol-soluble extract and gastrodin of the sliced Gastrodia elata decoction pieces were detected, and the results showed that the alcohol-soluble extract of the Gastrodia elata decoction pieces was 56.2%, the gastrodin 3.16%, and the water content 7.2%. After being placed in the open air indoors for 4 days, the measured moisture co...

Embodiment 3

[0053] refer to figure 1 , after washing Gastrodia elata, put it into the stainless steel plate of the far-infrared drying oven; turn on the far-infrared drying oven, set the time for 15 minutes, and carry out far-infrared vacuum softening at a temperature of 55 ° C. After slicing, put the gastrodia decoction pieces into the microwave In the stainless steel plate of the vacuum drying oven; turn on the microwave vacuum drying oven, vacuumize, and dry under the conditions of microwave setting 2450MHz, time 10min, temperature 55°C, vacuum degree -0.06MPa. There is a gelatinous layer on the surface of Gastrodia elata decoction pieces.

[0054] The alcohol-soluble extract and gastrodin in the sliced Gastrodia elata decoction pieces were detected, and the results showed that the alcohol-soluble extract in the Gastrodia elata decoction pieces was 54.6%, gastrodin 3.12%, and water 7.1%. After being placed in the open air indoors for 5 days, the measured moisture content was 7.4%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com