Hot-pressing sintering machine and temperature uniformity control method thereof

A technology of hot pressing sintering and temperature control devices, which is applied in the direction of furnace control devices, lighting and heating equipment, furnace types, etc., and can solve problems such as uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

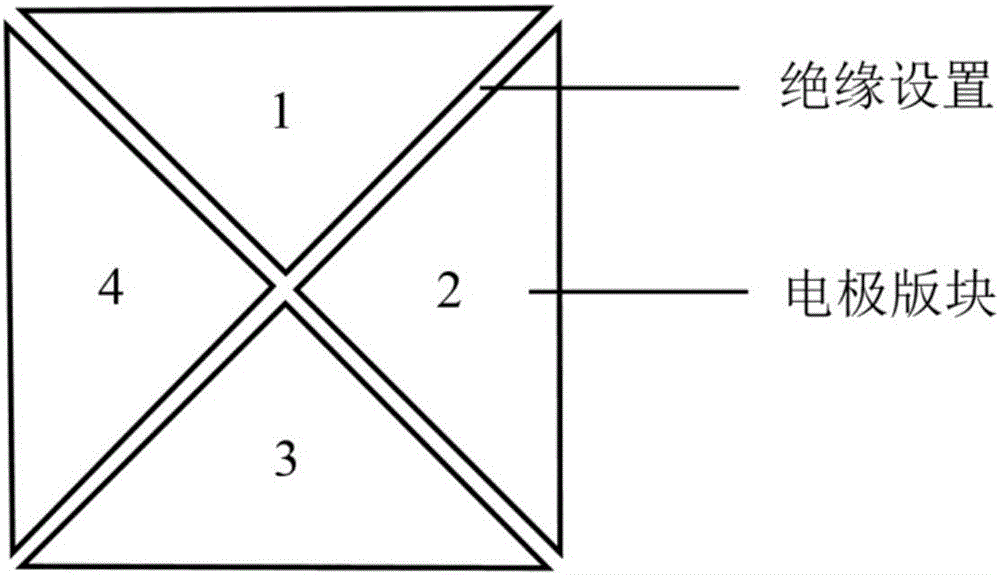

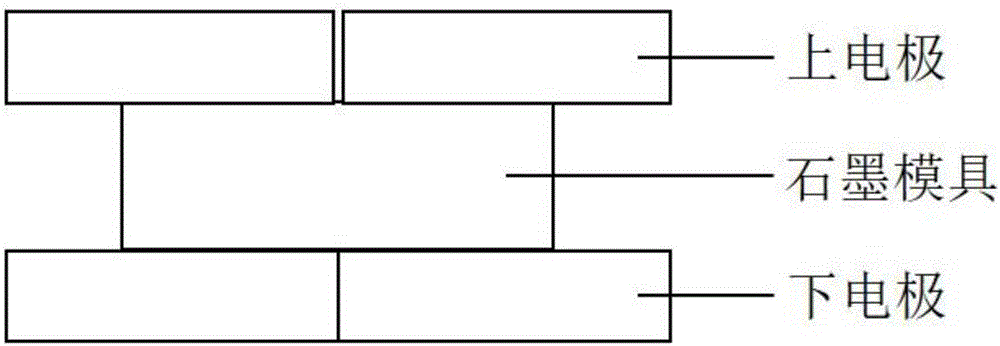

[0021] Such as figure 1 As shown, the upper electrode in the hot pressing sintering machine is divided into four parts, named: electrode block 1, electrode block 2, electrode block 3 and electrode block 4, each part is an isosceles right triangle. These 4 parts are insulated, and the insulation methods are as follows: insulation is set by insulating materials, or a certain distance is separated to realize the insulation, and the optional distance range is 1-10mm. There are no special requirements for the lower electrode, such as no treatment for the lower electrode, just use it directly, such as figure 2 As shown, it is a conductive whole. Therefore, the positional relationship between the upper and lower electrodes and the graphite mold is as follows image 3 shown. Since the upper electrode is divided into four parts, corresponding to these four electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com