Pressure sensing device with high sensitivity

A sensing device and high-sensitivity technology, which is applied in measurement devices, fluid pressure measurement using optical methods, and fluid pressure measurement. Measuring ranges, creating simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment example, the present invention will be further described:

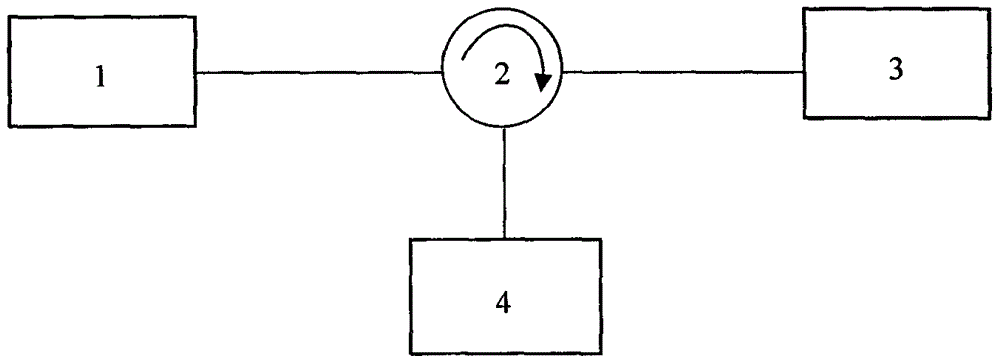

[0016] figure 1 Shown is a schematic diagram of an implementation and application system of the present invention, including a broadband light source 1 , a circulator 2 , a sensor head 3 , and a spectrum analyzer 4 . The connection method is as follows: the circulator 2 has three interface ports, namely: the light source inlet port, the light source outlet port, and the feedback port. The inlet port is connected to the broadband light source 1 , the outlet port is connected to the connecting sensor head 3 , and the feedback port is connected to the spectrum analyzer 4 .

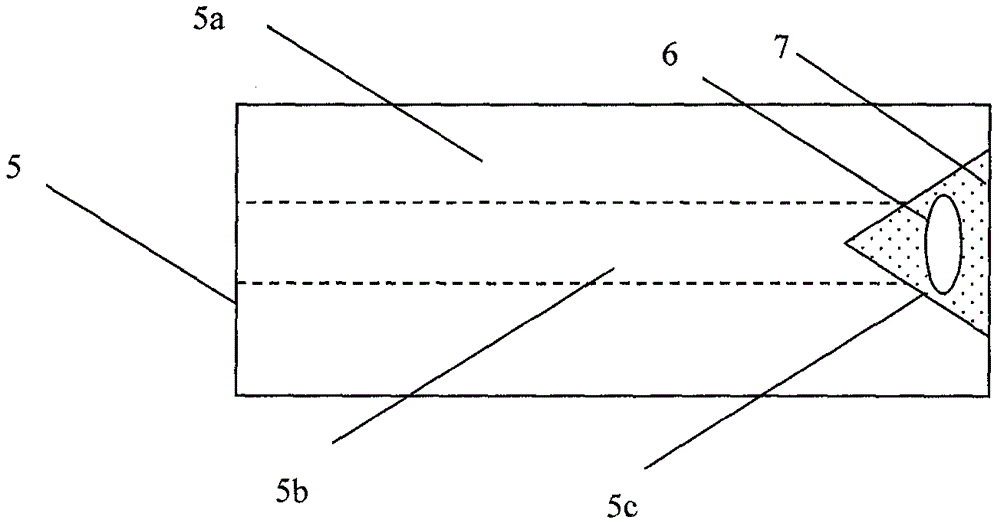

[0017] figure 2 Shown is a schematic structural view of the sensor head 3 of the present invention, the sensor head 3 is composed of an etched multimode fiber 5, an air cavity 6, and ultraviolet glue 7, and the corroded multimode fiber 5 includes a multimode fiber cladding 5a, T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com