Dynamic simulation engine testing system and method

A technology of dynamic simulation and test system, applied in the direction of engine test, general control system, control/regulation system, etc., can solve the problem of inability to accurately simulate the performance of the whole vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

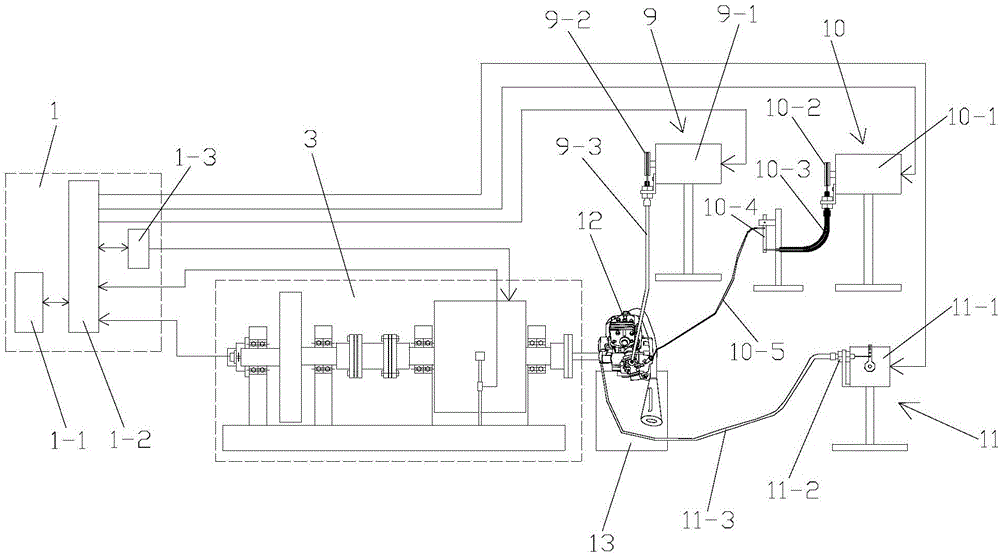

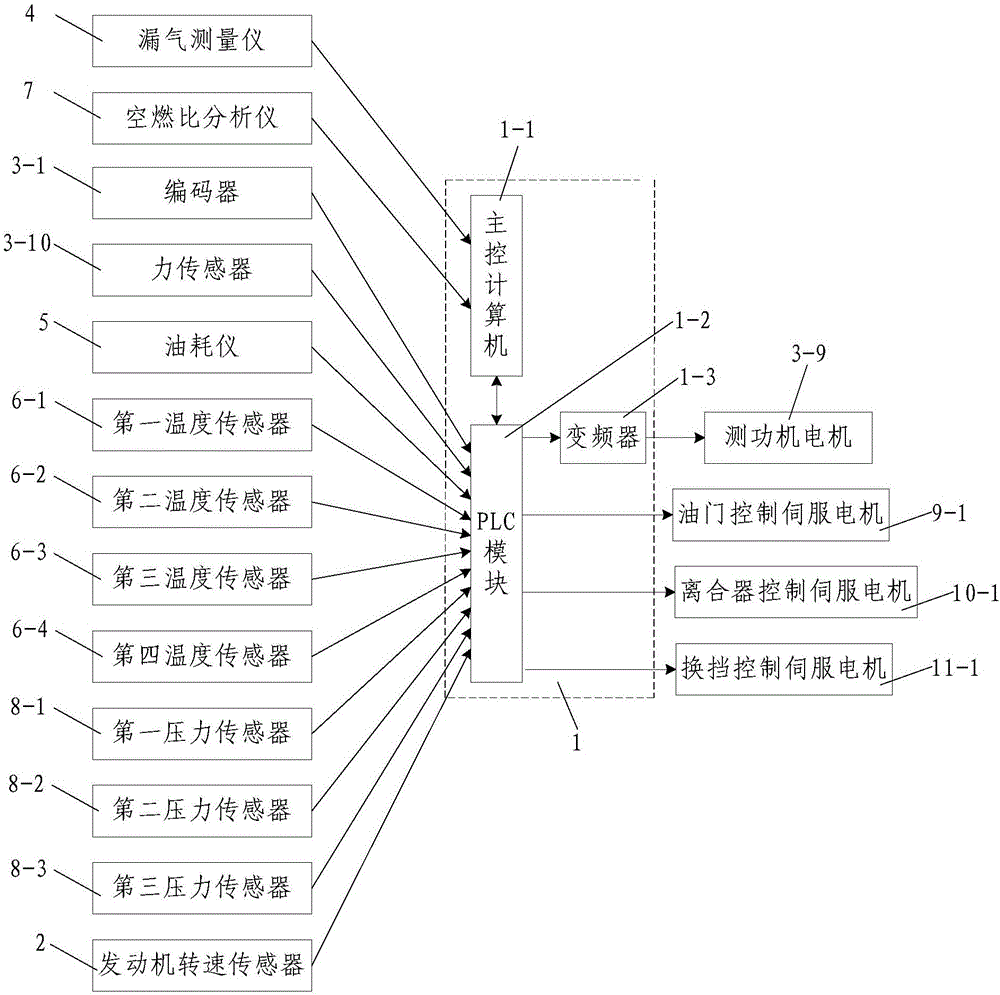

[0115] Such as figure 1 As shown, the dynamic simulation engine test system of the present invention comprises a dynamic simulation dynamometer 3, a sensing detection system, a control system 1 and an engine stand 13 for installing the engine to be tested 12, and for operating the engine to be tested 12 Accelerator operating mechanism 9, clutch operating mechanism 10 and shift operating mechanism 11;

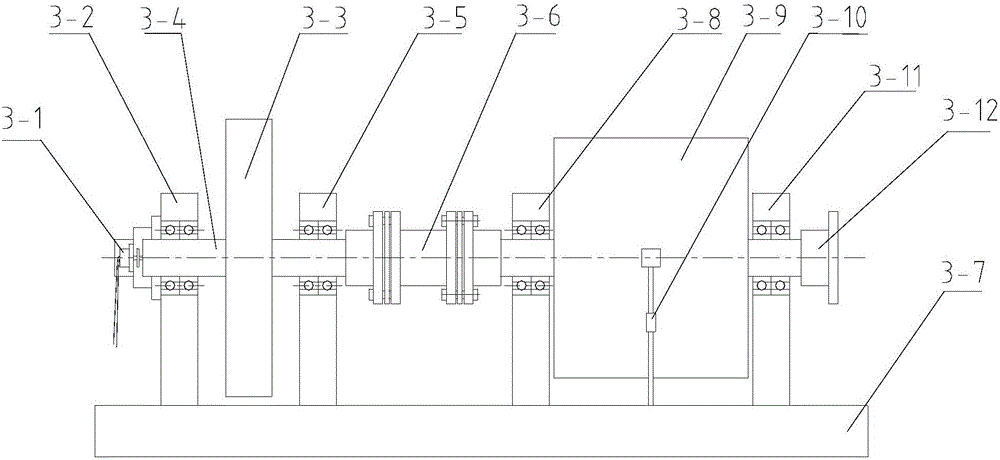

[0116] combine image 3 , the dynamic simulation dynamometer 3 includes a base 3-7 and a first inertia flywheel bearing support 3-2 fixedly connected to the base 3-7, a second inertia flywheel bearing support 3-5, a first motor bearing support 3 -8 and the second motor bearing support 3-11, the first inertia flywheel bearing support 3-2 and the second inertia flywheel bearing support 3-5 are equipped with a flywheel shaft 3-4, located at the first inertia flywheel bearing A flywheel shaft 3-4 between the support 3-2 and the second inertia flywheel bearing support 3-5 is connec...

Embodiment 2

[0185] Such as Figure 6 , Figure 7 and Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that the inertia flywheel is a flange type inertia flywheel 3-13, and the flange type inertia flywheel 3-13 includes a disc-shaped flange type flywheel body 3- 131 and the flanged flywheel installation hole 3-132 that is arranged at the center of the flanged flywheel body 3-131 and is used to connect the flywheel shaft 3-4, the two sides of the flanged flywheel body 3-131 The tops are all provided with circular weight-reducing process tanks 3-133. All the other structures are the same as in Example 1. By setting the weight-reducing process tank 3-133, a large-radius inertial flywheel can be realized with less material, and then the simulation of a larger inertia can be realized, which saves materials and costs, and expands the application range.

[0186] The dynamic simulation engine test method of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com