Automatically adjustable transformer room ventilation system

A transformer room and automatic adjustment technology, applied in the field of power transmission and transformation technology and automatic control, can solve the problems of dust accumulation on the transformer body and bushings, and easy pollution flashover accidents, so as to reduce pollution flashover accidents and reduce the time of direct connection , reduce the effect of dust accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

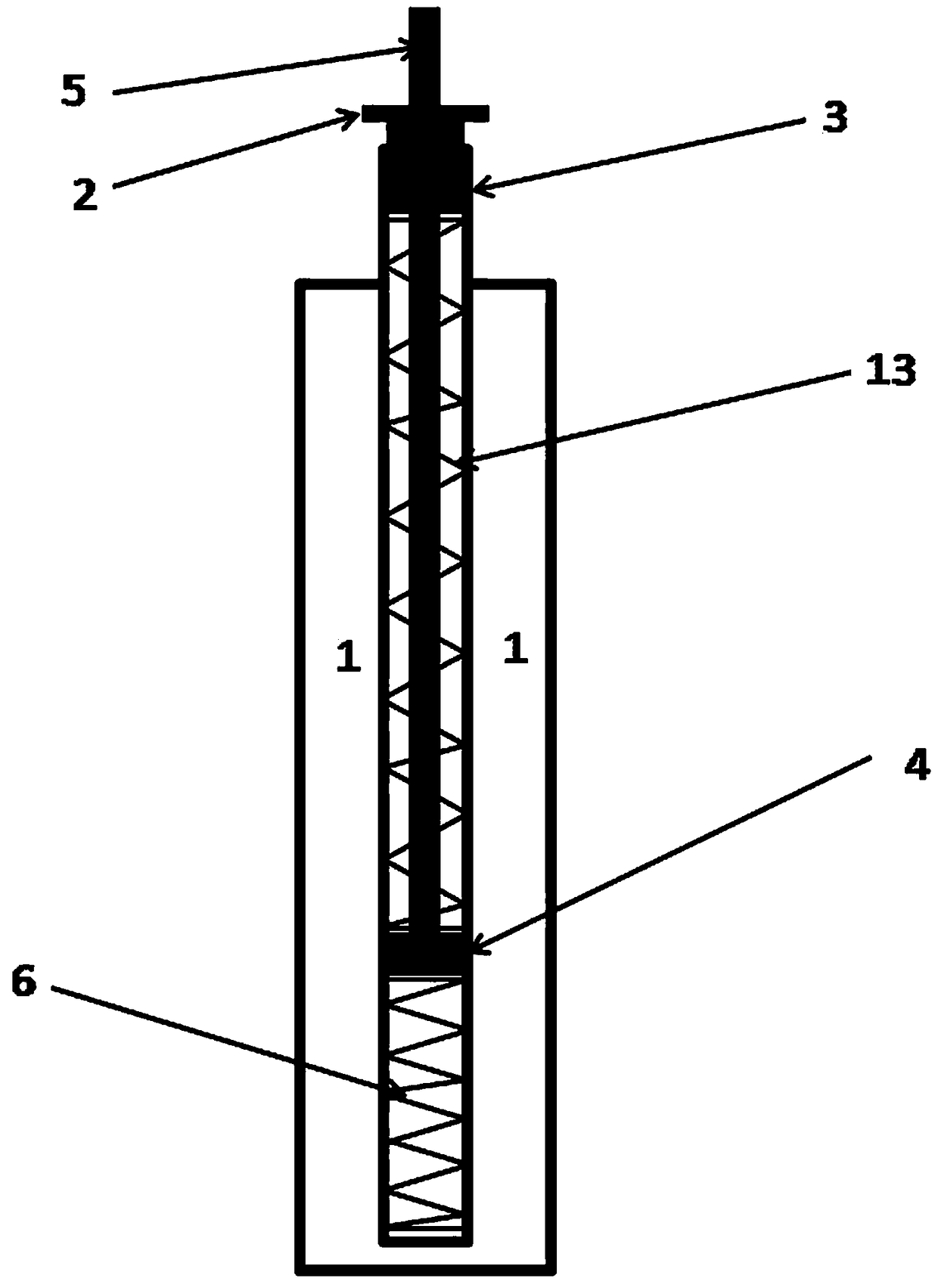

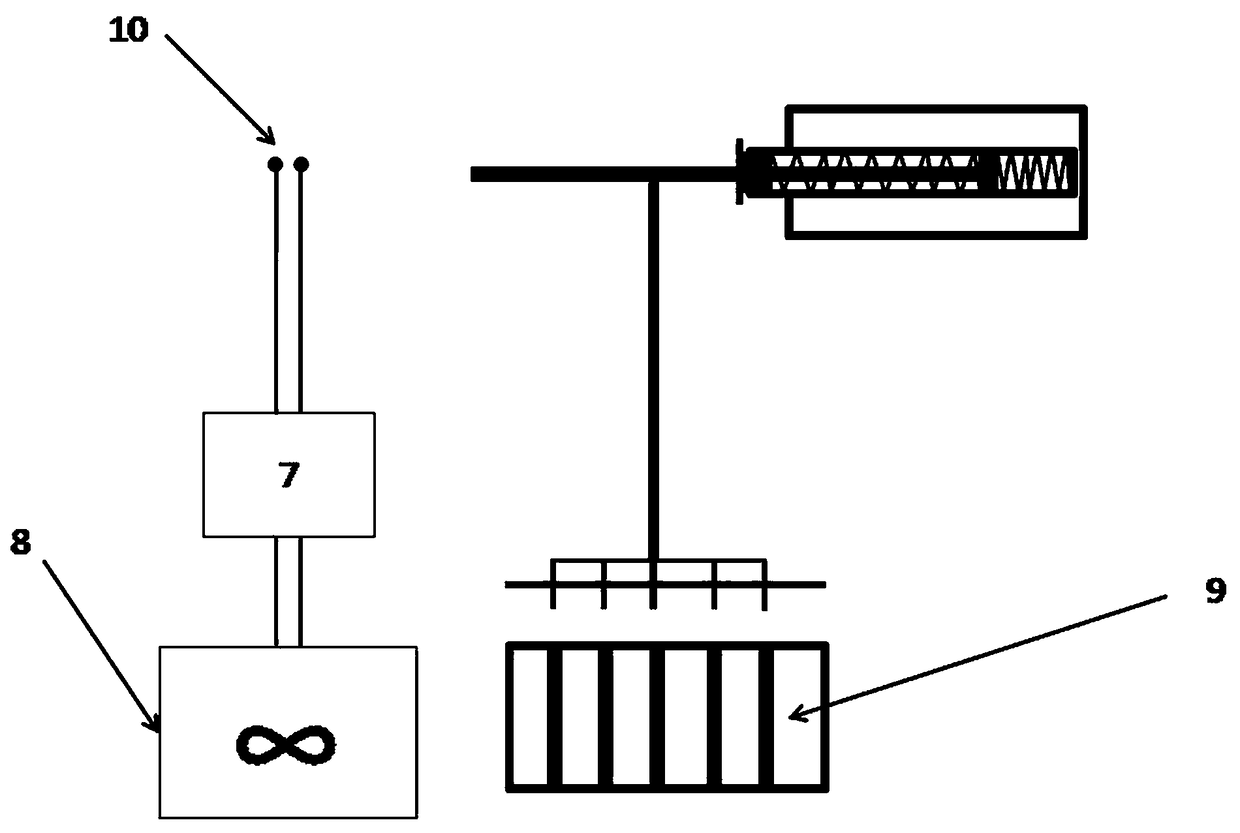

[0018] As shown in the figure, the present invention includes a vertical outer casing arranged in the ventilation channel of the transformer room, a vertical inner casing is arranged in the vertical outer casing, the vertical inner casing passes through the middle hole at the upper end of the vertical outer casing, and the vertical The lower end of the inner casing is opened and placed in the lower part of the vertical outer casing; the outer wall of the upper part of the vertical inner casing is airtightly connected with the inner wall of the middle hole.

[0019] The vertical inner casing is provided with a piston that can move up and down, and the inner space of the vertical inner casing at the lower part of the piston communicates with the inner space of the outer vertical outer casing of the vertical inner casing to form a gas chamber; the upper end of the piston is connected with the lower end of the vertical piston connecting rod, The upper end of the vertical piston con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com