Flocking imitated fur material and manufacturing method thereof

A production method and fur technology, applied in the field of flocking imitation fur materials and its production, can solve the problems of large amount of binder usage, increased embossing procedures, complicated production process, etc., and achieve production cost saving, smooth lines, and production The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

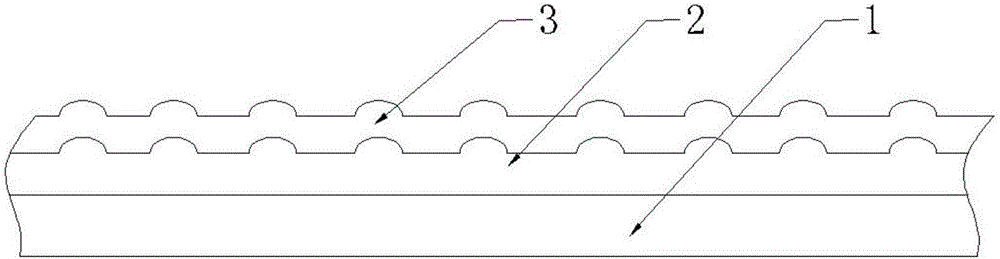

[0024] A flocking imitation fur material includes a base layer 1, one side of the base layer 1 successively includes a three-dimensional adhesive layer 2 and a fluff layer 3 adhered according to the adhesive layer structure. Wherein, the base layer 1 is a paper base layer, which has certain stiffness and toughness, and is convenient for making packaging cartons, photo frames, book covers, and the like. The fluff layer 3 is a chemical fiber of nylon material, and the length of the chemical fiber is 5-10mm.

[0025] The production method is:

[0026] (1) Setting the printing parameters: setting the printing parameters by analyzing the predetermined pattern in the computer, including forming the number of layers of the pattern forming layer, the height of the structure and the color of different heights;

[0027] (2) Velvet dyeing: dye the fluff fiber silk into the color required by the predetermined pattern, and put it into the flocking machine for standby;

[0028] (3) Three-...

Embodiment 2

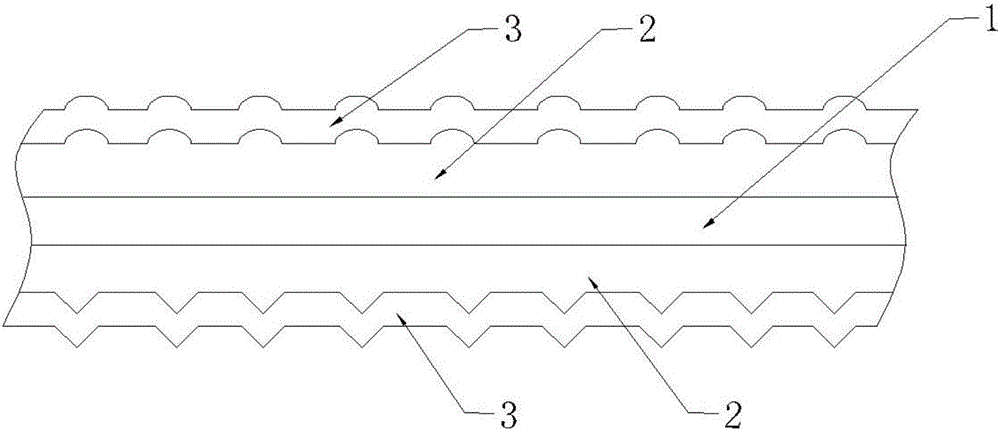

[0031] A flocking imitation fur material, comprising a base layer 1, one side of the base layer 1 successively includes a three-dimensional adhesive layer 2 and a fluff layer 3 adhered according to the structure of the adhesive layer, and the other side of the base layer 1 is successively a three-dimensional adhesive layer 2 and the fluff layer 3 adhered according to the adhesive layer structure. Wherein, the base layer 1 is double-sided flocking of the cotton cloth base layer, and the two sides can be of different patterns to form an AB version of the cloth. The fluff layer 5 is chemical fiber filaments of viscose fiber material, and the length of the chemical fiber filaments is 1-5mm.

[0032] The production method is:

[0033] (1) Setting the printing parameters: setting the printing parameters by analyzing the predetermined pattern on both sides in the computer, including forming the number of layers of the pattern forming layer, the height of the structure and the color ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com