Water-saving non-water-tank toilet with pressure washing system as well as assembling method of water-saving non-water-tank toilet

A water-saving, tankless technology, applied in flushing toilets, water supply devices, flushing equipment with water tanks, etc., can solve the problems of large blasting risk, heavy installation, large water tank space, etc., to reduce material and transportation costs, The effect of reducing the volume and length and increasing the force-bearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

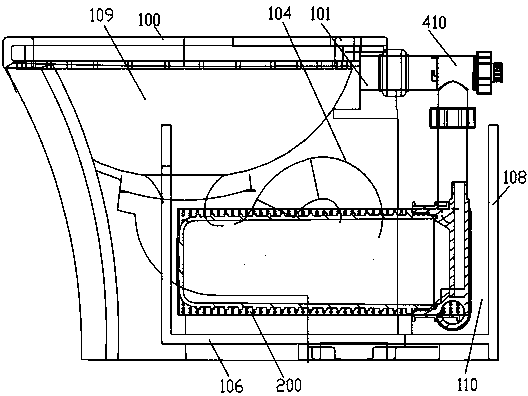

[0048] Example 1 Reference Figure 1 to Figure 8

[0049] A water-saving tankless toilet with a pressure flushing system, including an independent toilet seat 100, the independent toilet seat is not equipped with an independent water storage tank or a built-in water storage tank integrally formed with the independent toilet seat, the toilet of the independent toilet seat The bottom, back or side of the seat is provided with a water-saving flushing system 200 with the water inlet connected to the water supply system and with pressure energy storage. The water outlet of the flushing system is connected to the water inlet 101 of the independent toilet seat. A sewage outlet 102 for connecting the excreted waste is also arranged in the independent toilet seat. The above-mentioned pressure energy storage is air energy storage.

[0050] In this embodiment, the bottom of the independent toilet seat is provided with a bottom plate 106 connected to the two side walls of the independen...

Embodiment 2

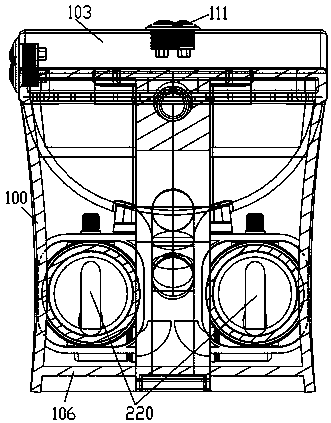

[0058] Example 2 Reference Figure 4 to Figure 9

[0059] A water-saving tankless toilet with a pressure flushing system, including an independent toilet seat 100, the independent toilet seat is not equipped with an independent water storage tank or a built-in water storage tank integrally formed with the independent toilet seat, the toilet of the independent toilet seat The bottom, back or side of the seat is provided with a water-saving flushing system 200 with the water inlet connected to the water supply system and with pressure energy storage. The water outlet of the flushing system is connected to the water inlet 101 of the independent toilet seat. A sewage outlet 102 for connecting the excreted waste is also arranged in the independent toilet seat.

[0060] In this embodiment, the bottom of the independent toilet seat is provided with a bottom plate 106 connected to the two side walls of the independent toilet seat, and the front and rear sides of the bottom plate are ...

Embodiment 3

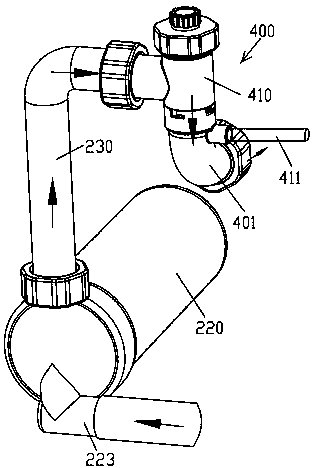

[0068] Example three reference Figure 4 to Figure 8 and Figure 10

[0069] A water-saving tankless toilet with a pressure flushing system, including an independent toilet seat 100, the independent toilet seat is not equipped with an independent water storage tank or a built-in water storage tank integrally formed with the independent toilet seat, the toilet of the independent toilet seat The bottom, back or side of the seat is provided with a water-saving flushing system 200 with the water inlet connected to the water supply system and with pressure energy storage. The water outlet of the flushing system is connected to the water inlet 101 of the independent toilet seat. A sewage outlet 102 for connecting the excreted waste is also arranged in the independent toilet seat.

[0070] In this embodiment, the bottom of the independent toilet seat is provided with a bottom plate 106 connected to the two side walls of the independent toilet seat, and the front and rear sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com