Standard pigsty

A pig house, standard technology, applied in animal houses, applications, animal husbandry, etc., can solve the problems of unsatisfactory ventilation and sewage discharge, and achieve the effect of facilitating feeding and cleaning, promoting circulation, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

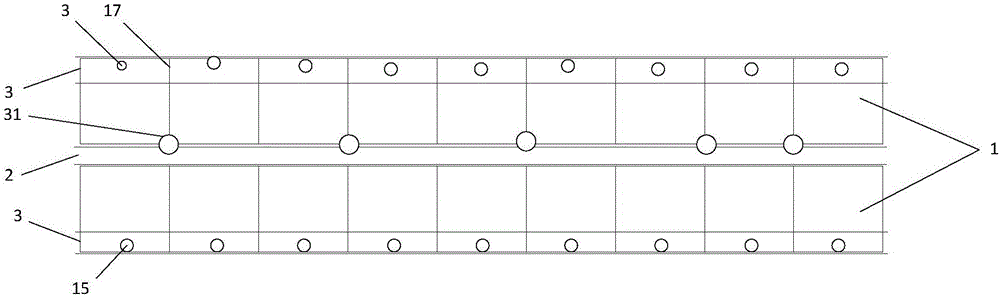

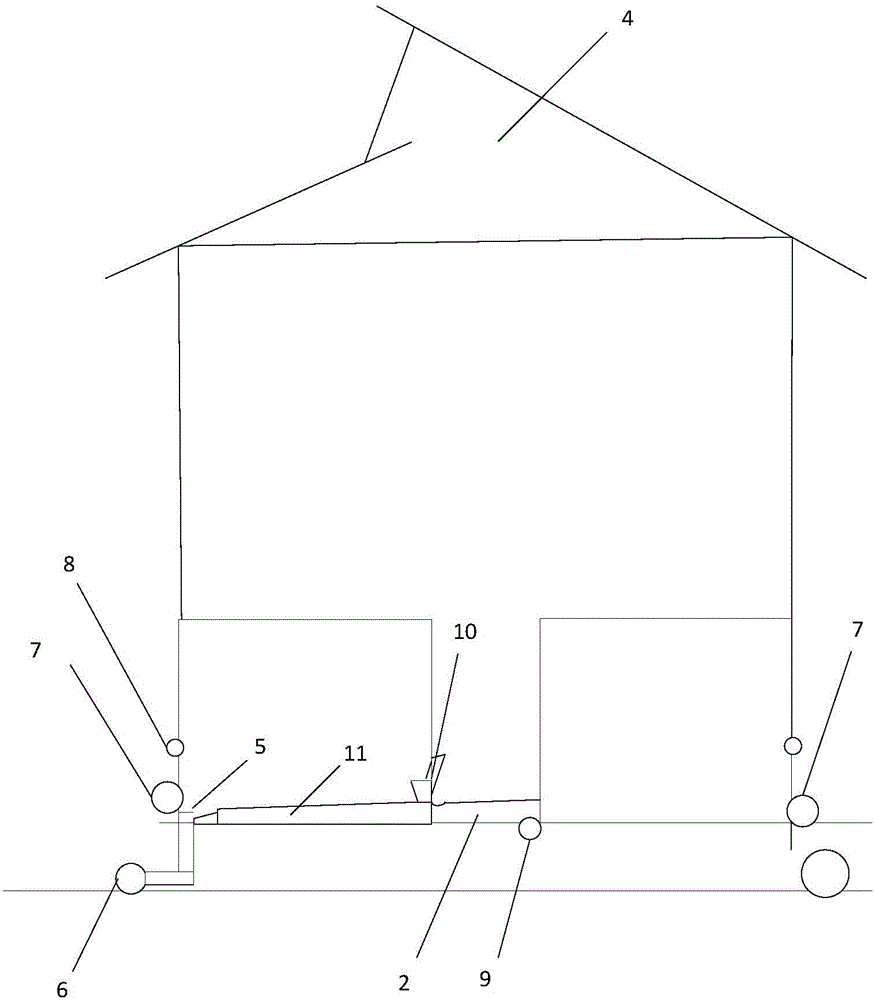

[0033] figure 1 It is a top view of a standard pig house, and Figure 2 is figure 1 Sectional view along A-A direction.

[0034] As shown in Figure 2(a), the standard pig house is divided into upper and lower layers. The upper layer is away from the ground and is the body of the pig house. The lower layer is flush with the ground and is the waste collection area for collecting pig feces, waste and wastewater. Between the upper layer and the lower layer The height difference is 0.8m.

[0035] The purpose of doing this is to realize the separation of breeding and waste collection, reduce the residue of waste in the breeding area, help maintain the hygienic environment of the breeding area, and at the same time facilitate the ventilation of the pig house and improve the environment in the pig house.

[0036] As shown in Figure 2(a), the pig house body on the upper floor of the standard pig house is surrounded by the roof 4 at the top and the wall at the bottom. The chamber is c...

Embodiment 2

[0043] As shown in FIG. 3( a ), each breeding area 1 includes a living area 18 and a sewage discharge area 3 . Wherein the living area 18 is close to the aisle 2, the width is 3.3m, and the length is 4m, and the side of the living area 18 near the aisle 2 is provided with a pigsty door, a cleaning water pipe 9 and a feed tank 10. One side of the sewage area 3 is adjacent to the living area 18, and the other side is the wall of the living area 18 away from the aisle 2. The length of the sewage area 3 is 4m, and the width is 1.2m. Hole 15, drainage hole 15 is connected with pig manure pipe 6 and communicates with the waste material collection area of pig house lower floor. As shown in Figure 2(a), one side wall of the sewage discharge area 3 is provided with a drinking water pipe 8 for pigs and a biogas slurry main pipe 7 for water tanks.

[0044] As shown in Figure 3(b), shale bricks are laid on the ground of breeding area 1. The ground of the living area 18 forms an inclin...

Embodiment 3

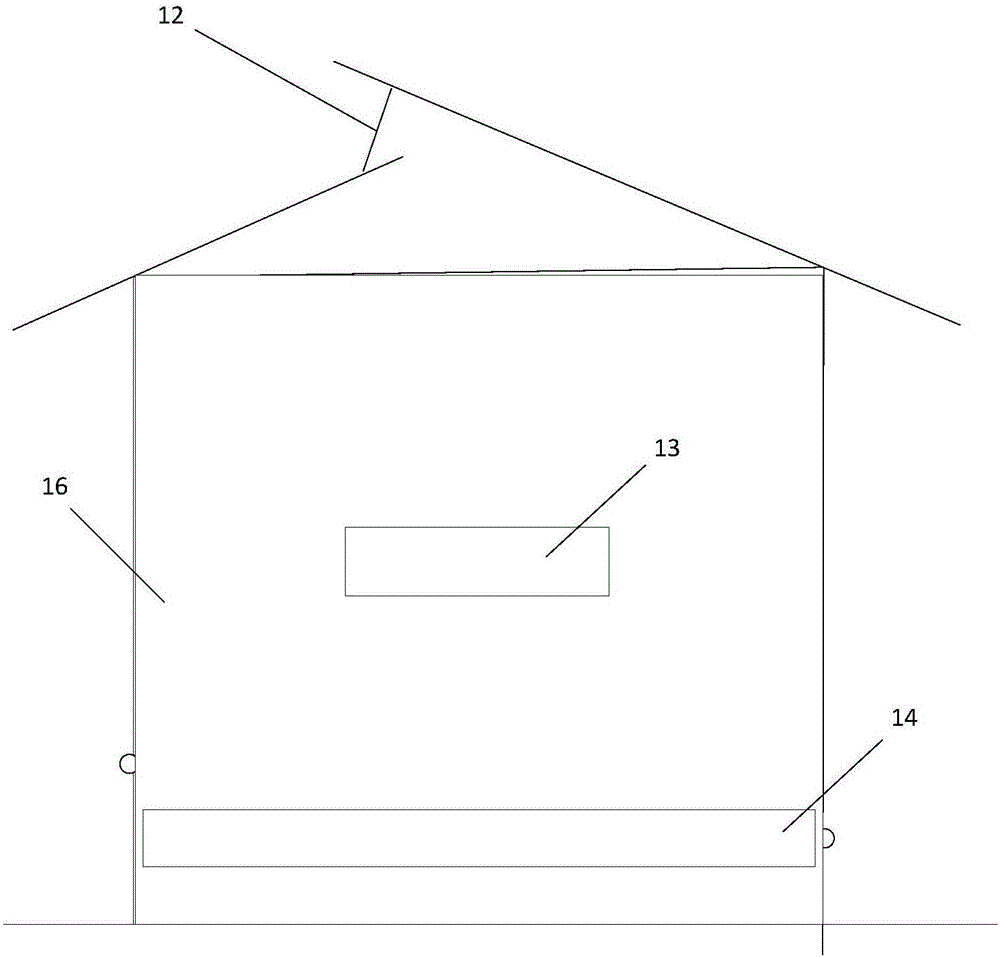

[0049] Such as Figure 6 As shown, the standard pig house also has a ventilation structure, which is divided into the ventilation structure of the pig house body and the lower ventilation structure.

[0050] Such as Figure 6 As shown, the wall of each sewage discharge area 3 is provided with ventilation windows 20, and the ventilation windows 20 are ventilation shutters. In the opposite two breeding areas 1, two ventilation windows 20 on the walls of both sides and the ventilation window 12 on the top of the house constitute a ventilation structure of the pig house body. There are multiple ventilation structures in the pig house body.

[0051] Its concrete principle is: the outside air enters in the pig house body through the ventilation windows 20 on both sides of the wall, mixes with the air in the pig house body, drives the air flow in the pig house body chamber, and the mixed air is in the air of the outside air. Driven to continuously rise through the breathable windo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com