Seasoning for hot and sour rice noodles

A technology of hot and sour powder and seasoning, which is applied in the direction of sugar-containing food ingredients, oil-containing food ingredients, and food ingredients as odor improvers, etc. It can solve the problems of inconsistent taste of seasoning, different taste of hot and sour powder, time-consuming and other problems , to achieve the effect of saving cooking time, obvious hot and sour characteristics, and uniform taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

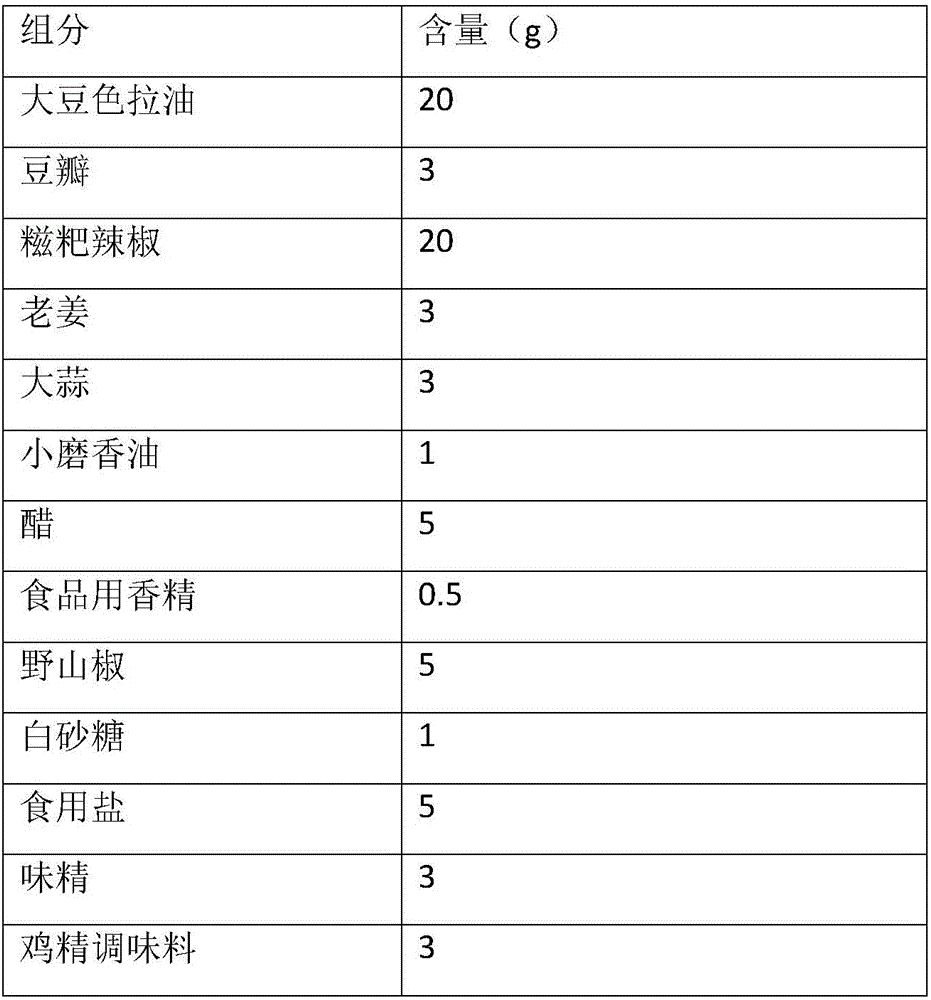

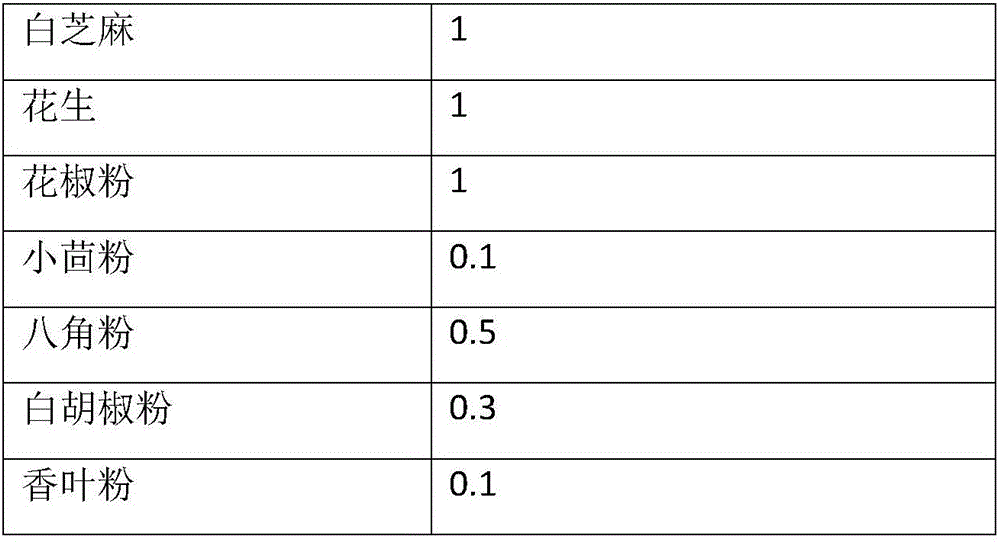

[0012] A kind of hot and sour powder seasoning, the mass parts of each component are as follows:

[0013]

[0014]

Embodiment 2

[0016] A kind of hot and sour powder seasoning, the mass parts of each component are as follows:

[0017]

[0018]

Embodiment 3

[0020] A kind of hot and sour powder seasoning, the mass parts of each component are as follows:

[0021] components

Content (g)

soybean salad oil

30

4

Ciba Chili

25

Ginger

4

garlic

4

small ground sesame oil

1

vinegar

8

1

wild pepper

8

White sugar

2

cooking salt

7

monosodium glutamate

4

Chicken Seasoning

4

White sesame

1

peanut

1

pepper powder

1

cumin powder

1

star anise powder

0.5

White pepper

0.5

Geranium powder

0.3

[0022] The preparation method of hot and sour powder seasoning is as follows:

[0023] ① Raw material preparation

[0024] Prepare raw materials according to Example 1: soybean salad oil 20g; watercress 3g; glutinous rice cake pepper 20g; ginger 3g; garlic

[0025] 3g; small ground sesame oil 1g; vinegar 5g; food flavor 0.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com