A continuous frying equipment

A kind of equipment and roasting technology, which is applied in the fields of application, food processing, food science, etc., can solve the problems of energy saving and emission reduction, polluting the production environment of the workshop, and affecting the quality of fried materials, so as to shorten the roasting time and achieve the goal of roasting. The effect of shortening the time and speeding up the flow of hot air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiments are described below with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solution of the invention described in the claims.

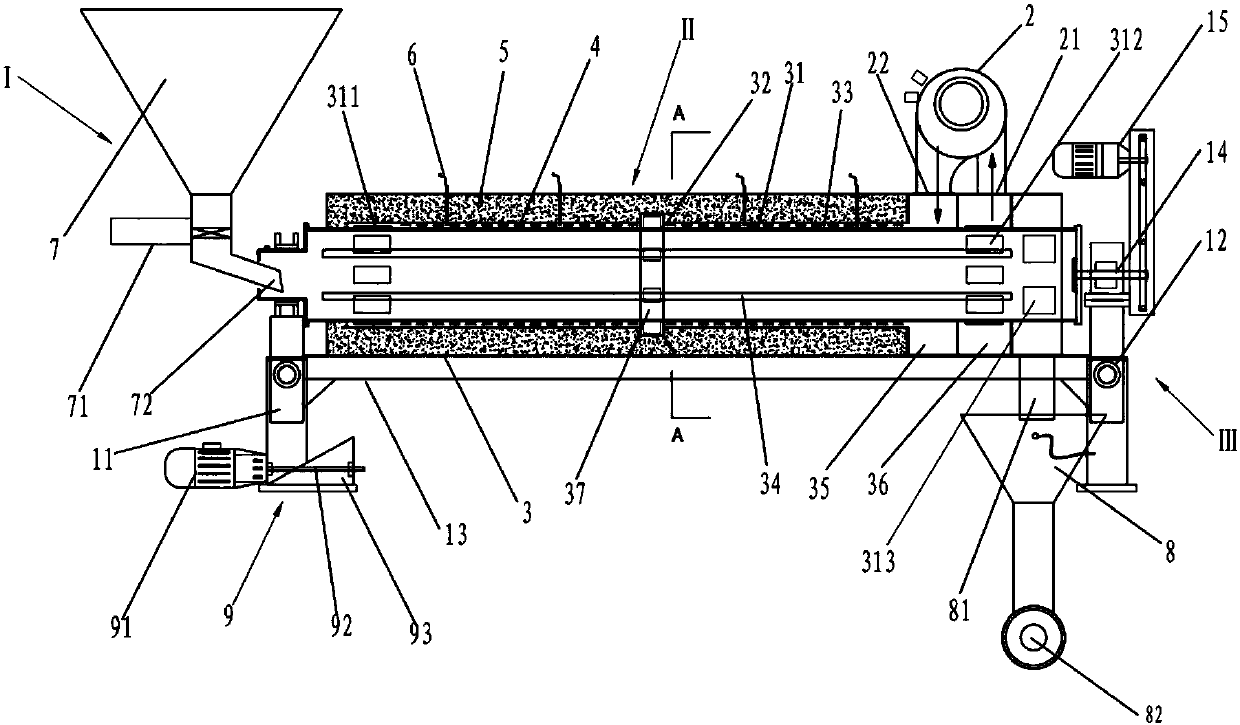

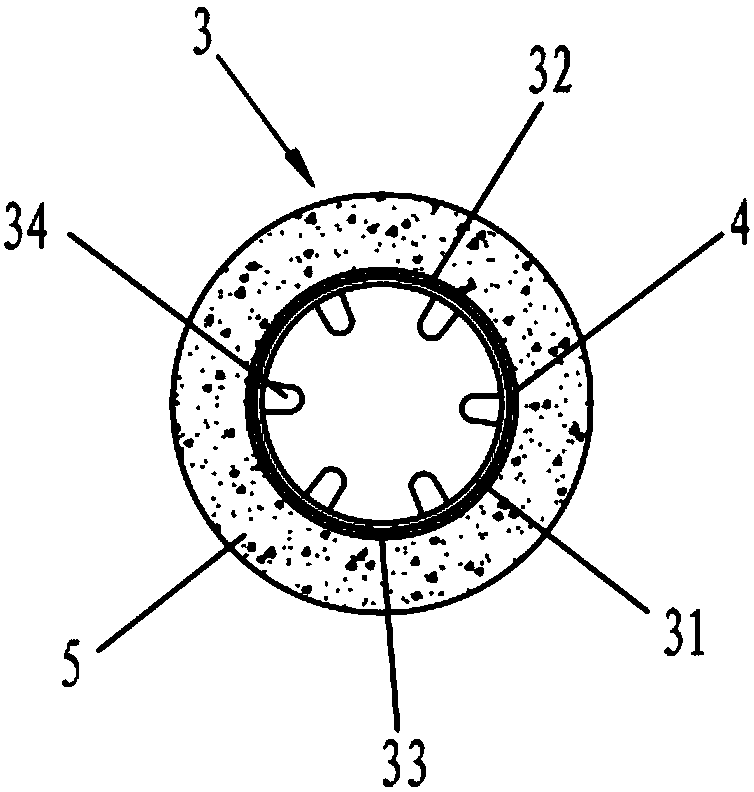

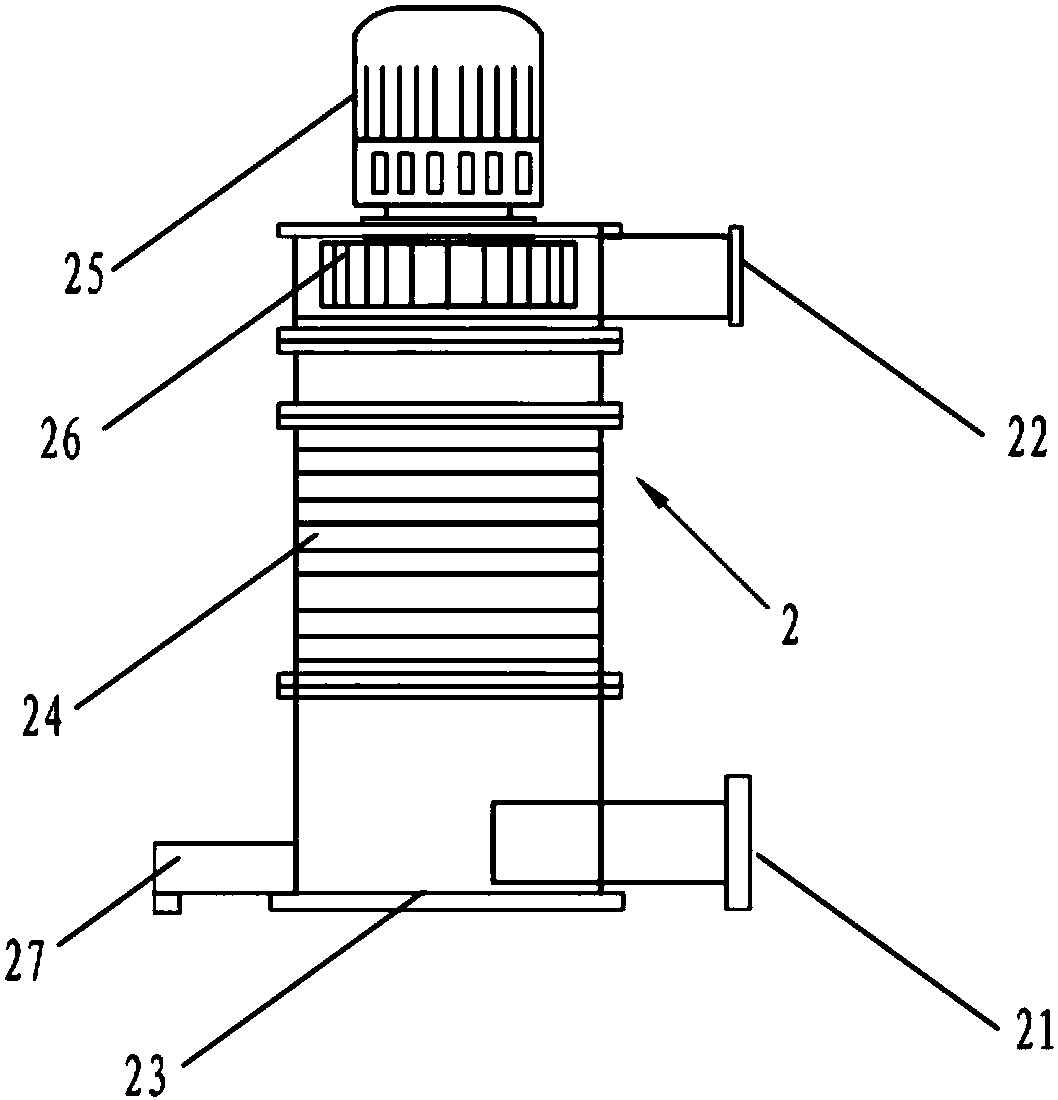

[0031] Such as figure 1 As shown, a continuous roasting and frying equipment includes a frame 1, a feeding mechanism I, a frying mechanism II, a discharge mechanism III and an oil separation and collection device 2. The two ends of the frying mechanism II pass through the rotating bearing seat respectively 14 is installed on the frame 1 and is driven to rotate around its axis by the geared motor 15. The feeding mechanism I and the discharging mechanism III are respectively arranged at the feeding end and the discharging end of the frying mechanism II and communicated with the frying mechanism II; Such as figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com