Biguanide type waste gas treatment system

A technology of waste gas treatment and biguanides, which is applied in the direction of gas treatment, membrane technology, and separation of dispersed particles, which can solve environmental and air quality pollution, and can not eliminate the root cause of waste gas pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

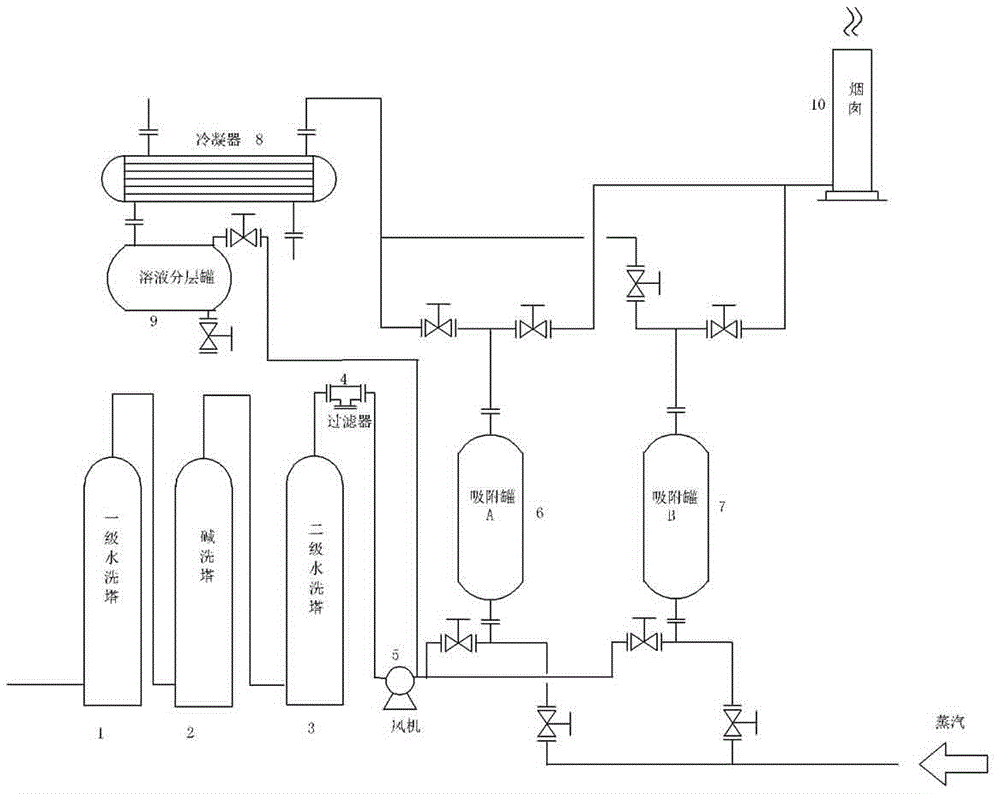

[0019] The technical solution and structure of the present invention will be described below in conjunction with the accompanying drawings, so as to facilitate the understanding of those skilled in the art.

[0020] As shown in Figure 1, a biguanide waste gas treatment system includes a waste gas treatment device and a waste gas recovery device. Exhaust gas treatment device The first-level water washing tower 1, the alkali washing tower 2, and the second-level water washing tower 3 are made of glass fiber reinforced plastics; the rear of the second-level water washing tower 3 is connected to the waste gas recovery device, and the waste gas recovery device includes filter 4, fan 5, and adsorption tank A6 , adsorption tank B7, condenser 8 and solvent stratification tank 9 are made of stainless steel. The first water washing tower 1, the alkali washing tower 2, the second water washing tower 3, the lower side of the adsorption tank A6, and the lower part of the adsorption tank B7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com